Introduction

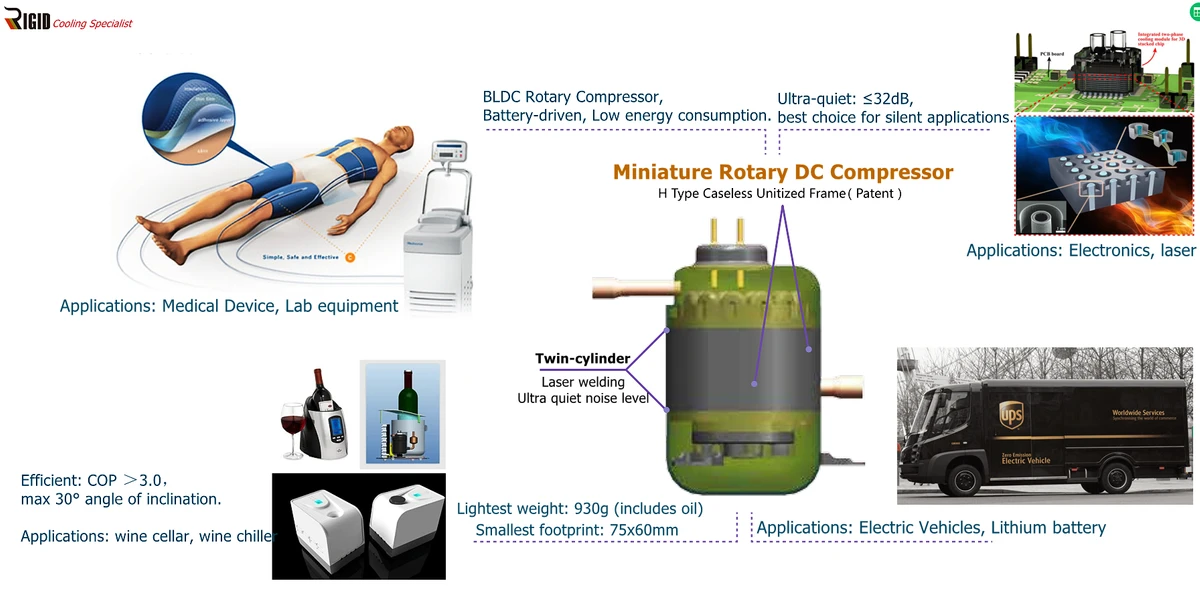

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of cooling systems, oil separator refrigeration plays a pivotal role in enhancing efficiency and performance. These specialized devices not only optimize the operation of refrigeration systems but also ensure longevity and reliability across various applications, including cold storage facilities. Understanding how oil separators function and their significance can help businesses maximize their cooling capabilities.

Understanding Oil Separator Refrigeration

Oil separator refrigeration involves the use of devices designed to separate refrigerant oil from the gas in a cooling system. This process is crucial for maintaining optimal performance, as it prevents oil contamination that can impair efficiency and lead to system failures. By effectively managing oil within these systems, operators can ensure that their equipment operates smoothly and reliably.

The Importance of Efficiency in Cooling Systems

Efficiency is paramount in any cooling system, especially in industries where energy costs are a significant concern. High-efficiency systems not only reduce operational expenses but also contribute to environmental sustainability by minimizing energy consumption. In this context, understanding what is the use of an oil separator in cold storage becomes essential; it ensures that refrigeration units run at peak efficiency while extending their lifespan.

Key Functions of Oil Separators

Oil separators serve several key functions within refrigeration systems, particularly in compressors where they manage lubrication effectively. One primary function is to prevent excess oil from circulating back into the refrigerant lines, which can lead to reduced cooling capacity and increased wear on components. Additionally, different types of refrigeration oil separators are designed to cater to varying needs—ensuring that businesses can choose the right solution for their specific applications while optimizing overall system performance.

What is Oil Separator Refrigeration?

Oil separator refrigeration is a critical component in modern cooling systems. It involves using specialized devices to separate oil from refrigerants, ensuring the efficient operation of refrigeration systems. By maintaining optimal oil levels, these separators play a vital role in enhancing the performance and longevity of cooling equipment.

Definition and Overview

An oil separator in refrigeration is designed to remove oil from the refrigerant flow before it returns to the compressor. This process helps maintain a clean and efficient system, preventing potential damage caused by excessive oil buildup. Essentially, it ensures that the refrigerant can effectively absorb heat without interference from oil residues.

The use of an oil separator in cold storage is particularly significant, as these systems require consistent and reliable cooling performance. By separating oils efficiently, the system can maintain lower temperatures for longer periods without compromising on energy consumption or overall effectiveness. This is essential for businesses that rely on cold storage solutions to preserve perishable goods.

How Oil Separators Enhance Efficiency

Oil separators enhance efficiency by ensuring that compressors operate with minimal friction and maximum output. When excess oil accumulates within the compressor, it can lead to reduced performance and increased energy consumption—definitely not what you want when you're trying to keep your costs down! By effectively removing this excess oil, separators help maintain optimal operating conditions.

Moreover, when discussing what is the function of an oil separator in a compressor, it's clear that these devices facilitate better heat exchange within the system. This means that refrigeration units can achieve desired temperatures faster while using less energy—an appealing prospect for any business owner looking to improve their bottom line! The result? A more sustainable approach to cooling operations.

The Role in Cold Storage Systems

In cold storage environments, maintaining consistent temperatures is paramount; this is where an effective refrigeration oil separator shines! These systems prevent fluctuations that could compromise product quality or safety by ensuring proper refrigerant flow without excessive oils interfering with heat exchange processes.

Additionally, understanding how does an oil separator work in refrigeration helps clarify its importance in avoiding costly maintenance issues down the line. By keeping compressors running smoothly and efficiently, businesses can focus on their core operations rather than worrying about equipment failures or unexpected downtime—which could be disastrous for perishable inventory!

Ultimately, RIGID's innovative approach to mini compressor solutions exemplifies how modern technology meets these needs head-on. With their focus on compact designs tailored for specific applications like micro refrigeration & air conditioning systems, RIGID ensures clients receive top-notch products that enhance efficiency across various industries—making them leaders in this space!

What is the Use of an Oil Separator in Cold Storage?

In cold storage systems, the role of an oil separator is pivotal for maintaining optimal refrigeration performance and ensuring system reliability. The oil separator refrigeration technology effectively segregates oil from the refrigerant, thereby enhancing cooling efficiency and preventing potential operational issues. Understanding what is the use of an oil separator in cold storage can significantly impact how businesses manage their refrigeration systems.

Maintaining Refrigeration Performance

One of the primary functions of an oil separator is to maintain refrigeration performance by ensuring that only clean refrigerant flows through the system. Oil can accumulate in various parts of a refrigeration unit, leading to reduced efficiency and increased energy consumption. By implementing effective oil separation techniques, operators can optimize energy usage while prolonging equipment life, which is essential for any cold storage facility aiming for sustainability.

Preventing Oil Contamination in Systems

Preventing oil contamination in cooling systems is another crucial benefit provided by an oil separator. Contaminated refrigerants can lead to compressor failures and decreased overall system performance, which could be financially detrimental for businesses relying on cold storage solutions. The use of a well-designed oil separator ensures that contaminants are filtered out effectively, safeguarding both system integrity and product quality.

Case Study: Cold Storage Solutions

Consider a case study involving a large-scale cold storage facility that faced challenges with compressor failures due to excessive oil contamination. By integrating advanced refrigeration oil separator types into their existing systems, they were able to drastically reduce downtime and maintenance costs while improving overall efficiency. This real-world example highlights how understanding what is the function of an oil separator in compressor applications directly translates into enhanced operational effectiveness within cold storage environments.

What is the Function of Oil Separator in Compressor?

Oil separators play a crucial role in maintaining the efficiency and reliability of refrigeration compressors. By effectively managing oil within the system, these separators ensure that compressors operate at optimal performance levels, preventing potential damage and inefficiencies. Understanding what is the function of an oil separator in a compressor can significantly enhance system longevity and effectiveness.

Oil Management in Compressors

An oil separator for compressor applications works by extracting excess oil from the refrigerant vapor before it re-enters the compressor. This not only helps maintain lubrication but also prevents issues such as foaming and contamination, which could lead to costly repairs or replacements.

Furthermore, proper oil management ensures that the right amount of lubricant circulates throughout the system. This balance is vital because too much oil can reduce heat transfer efficiency, while too little can lead to wear and tear on moving parts. In essence, understanding what is the use of an oil separator in cold storage systems reflects its importance in maintaining optimal compressor function.

Impact on Overall System Efficiency

The impact of an effective oil separator on overall system efficiency cannot be overstated; it’s like having a well-tuned engine under your hood. By removing excess oil from refrigerant gases, these separators help maintain consistent pressure levels within the compressor, leading to improved energy efficiency and reduced operational costs. When we consider refrigeration oil separator types available today, each design aims to maximize this efficiency while minimizing energy consumption.

Moreover, when compressors run smoothly due to effective oil management facilitated by separators, they contribute significantly to lower greenhouse gas emissions—an increasingly important factor in today's eco-conscious market landscape. Thus, investing in high-quality separators not only enhances performance but also aligns with sustainability goals that many companies are now prioritizing.

RIGID's Approach to Compressor Solutions

RIGID stands out as a mini compressor innovation leader in China with its commitment to superior design and uncompromising quality when it comes to refrigeration solutions. With a focus on developing advanced technologies for mobile and compact cooling systems, RIGID integrates state-of-the-art oil separation techniques into their products for unparalleled performance. Their approach ensures that clients receive custom-made refrigeration solutions tailored specifically for their needs—whether it's micro refrigeration or air conditioning applications.

By prioritizing clients' budgets while enhancing competitiveness through innovative designs, RIGID has built a growing list of satisfied customers who rely on their expertise in mini compressors and small chillers alike. As they continue pushing boundaries within the micro cooling industry, RIGID exemplifies how modern technology can optimize what is the function of an oil separator in compressor systems while delivering exceptional results across various applications.

Refrigeration Oil Separator Types

Different Types Explained

Refrigeration oil separators come in several types, each designed to serve specific functions within an oil separator refrigeration system. Common types include centrifugal separators, coalescing filters, and magnetic separators. Each of these types utilizes different mechanisms to separate oil from refrigerant, enhancing overall efficiency and preventing contamination—a critical factor when considering what is the use of an oil separator in cold storage.

Centrifugal separators rely on high-speed rotation to force heavier oil particles out of the refrigerant stream, while coalescing filters capture smaller droplets by merging them into larger ones for easier removal. Magnetic separators utilize magnetic fields to attract ferrous contaminants from the refrigerant flow, ensuring that only clean refrigerants reach your compressor. Understanding these differences helps clarify what is the function of an oil separator in compressor systems.

Choosing the Right Separator for Your Needs

Selecting the appropriate refrigeration oil separator requires careful consideration of various factors such as system size, type of refrigerant used, and specific application requirements. It's essential to assess how each type manages oil separation effectively while maintaining optimal performance levels within your cooling system. Knowing how does an oil separator work in refrigeration can guide you towards making an informed decision tailored to your unique needs.

For instance, if you're working with a large-scale cold storage facility where efficiency is paramount, a centrifugal separator might be ideal due to its ability to handle high volumes with minimal maintenance. Conversely, smaller systems may benefit more from coalescing filters that offer excellent filtration without taking up too much space or requiring extensive modifications. RIGID's innovative approach provides custom solutions that cater specifically to client budgets and operational requirements—ensuring you get precisely what you need without unnecessary frills.

Innovations in Separator Design

Innovation plays a pivotal role in enhancing the effectiveness of refrigeration oil separators across various applications today. Recent advancements have led to designs that improve separation efficiency while reducing energy consumption—ideal for businesses looking to boost their competitiveness without breaking the bank on energy costs. RIGID’s commitment to capturing new technologies means they are at the forefront of these innovations.

One notable trend involves integrating smart technology into separator designs that monitor performance metrics in real-time; this allows users not only better oversight but also predictive maintenance capabilities—anticipating issues before they escalate into costly repairs or downtime! Additionally, advancements such as compact designs enable easier installation even within tight spaces typical of micro cooling applications like those provided by RIGID’s lineup: mini compressors and small chillers are prime examples where efficient design matters most.

In summary, understanding refrigeration oil separator types equips businesses with essential knowledge for optimizing their cooling systems efficiently while also addressing critical considerations around performance longevity and cost-effectiveness—all key elements highlighted by RIGID's approach toward modern refrigeration solutions.

How Does an Oil Separator Work in Refrigeration?

In the realm of refrigeration, understanding how an oil separator works is crucial for maintaining system efficiency and performance. An oil separator plays a vital role in ensuring that the refrigerant remains free from oil contamination, which can hinder cooling effectiveness. By effectively separating oil from refrigerants, these devices enhance the overall functionality of refrigeration systems, including those used in cold storage.

The Process Explained Step by Step

The process of oil separation begins as the refrigerant circulates through the compressor and into the condenser. During this phase, some oil gets mixed with the refrigerant due to high pressures and temperatures. The oil separator refrigeration unit then employs centrifugal force or gravity to separate the oil from the refrigerant; this is typically achieved through a series of baffles or filters that allow for efficient separation.

Once separated, the recovered oil is directed back into the compressor while clean refrigerant continues its journey through the system. This process not only ensures that compressors operate smoothly but also answers What is the use of an oil separator in cold storage?—by maintaining optimal cooling performance without interruptions caused by excess oil buildup. Ultimately, a well-functioning oil separator significantly contributes to energy savings and extended equipment lifespan.

Benefits of Effective Oil Separation

Effective oil separation provides numerous benefits that impact both efficiency and reliability within refrigeration systems. First and foremost, it prevents issues related to excessive lubrication that can lead to compressor failure—addressing What is the function of an oil separator in a compressor? directly by ensuring proper lubrication levels are maintained without flooding any components.

Moreover, effective separation translates into improved heat exchange processes within cold storage applications; this means more consistent temperatures and reduced energy consumption over time. Additionally, knowing various refrigeration oil separator types allows operators to choose solutions tailored specifically for their needs—ensuring compatibility with their existing systems while maximizing performance.

Real-World Applications and Success Stories

Real-world applications highlight just how critical an efficient oil separator can be across different industries—from food preservation in cold storage facilities to pharmaceutical distribution requiring precise temperature control. For instance, RIGID has successfully implemented innovative mini compressors equipped with advanced refrigeration oil separators designed for compact cooling systems in various settings.

One success story involves a large-scale cold storage facility that experienced significant energy savings after installing RIGID's custom-designed solutions featuring state-of-the-art separators. By addressing key operational challenges—such as maintaining optimal temperatures without excessive energy costs—they demonstrated just how transformative proper technology can be when integrated into everyday operations.

Conclusion

In the world of refrigeration, the role of oil separators cannot be overstated. They enhance cooling system longevity and efficiency, ensuring that compressors operate at peak performance. As we’ve explored, understanding oil separator refrigeration is essential for anyone involved in cold storage or compressor systems.

Enhancing Cooling System Longevity

The importance of effective oil management in refrigeration systems is critical to their longevity. By utilizing an oil separator, operators can maintain optimal performance and prevent potential failures due to oil contamination. This proactive approach not only extends the life of compressors but also enhances overall system reliability.

RIGID's Role in Modern Refrigeration

RIGID stands out as a mini compressor innovation leader in China, focusing on advanced technologies for mobile and compact cooling systems. With a commitment to superior design and uncompromising quality, RIGID offers tailored solutions that leverage the latest advancements in refrigeration oil separator types. Their expertise ensures that clients receive custom-made solutions that meet specific needs while boosting competitiveness in the market.

Boosting Efficiency in Competitive Markets

In today's competitive landscape, efficiency is key to staying ahead, and this is where an effective oil separator shines. By understanding what is the function of an oil separator in a compressor and how it works within refrigeration systems, businesses can optimize their operations significantly. RIGID’s innovative approach not only addresses these needs but also empowers clients to make informed decisions about their cooling solutions.