Introduction

RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems.

In today's fast-paced world, understanding cold plate technology is crucial for effective thermal management in various industries. As companies strive to optimize performance and efficiency, water cooled systems and liquid cooling have emerged as innovative solutions to address heat dissipation challenges.

Understanding Cold Plate Technology

What is a cold plate? It's a crucial component in thermal management, designed to efficiently dissipate heat from electronic devices and equipment. By utilizing the principles of conduction, cold plates effectively transfer heat away from sensitive components, ensuring optimal performance and reliability.

Cold plates are essential for maintaining the optimal operating temperature of electronic devices and equipment. Without proper thermal management, these devices can overheat, leading to decreased performance and potential damage. By effectively dissipating heat through conduction, cold plates play a critical role in ensuring the reliability and longevity of sensitive components.

Importance of Thermal Management

Effective thermal management is essential for preventing overheating and ensuring the longevity of electronic devices. With the continuous demand for high-performance systems, the need for efficient cooling solutions has never been more critical. Cold plate technology plays a pivotal role in maintaining optimal operating temperatures.

Let's delve deeper into their specific benefits and applications:

The Cold Plate Advantage

- Precise Temperature Control: Cold plates maintain consistent temperatures across large heat-generating surfaces. This precision is vital for sensitive electronic components.

- Efficient Heat Dissipation: Cold plates maximize heat transfer by distributing heat evenly to a coolant, preventing hotspots and ensuring optimal performance.

- Compact Design: Cold plates can be integrated into compact spaces, making them ideal for devices with limited room for cooling solutions.

- Versatility: Cold plates can be used in various applications, from electronics and servers to automotive and aerospace industries.

By understanding the critical role of cold plates in thermal management, engineers and designers can develop more efficient and reliable products.

Water Cooled Systems and Liquid Cooling

Water cooled systems and liquid cooling have gained traction as advanced methods for managing heat in various applications. These innovative solutions offer enhanced thermal performance and are increasingly integrated into electronic devices, industrial machinery, and high-performance computing systems. One key component of liquid cooling systems is the cold plate, a heat exchanger that transfers heat from the electronic components to the liquid coolant. Cold plates are designed with intricate channels to maximize the contact area between the coolant and the hot components, ensuring efficient heat transfer. As a result, cold plates play a crucial role in maintaining optimal operating temperatures for high-power electronics and other heat-generating equipment.

What is a Cold Plate?

The Basics of Cold Plate Cooling

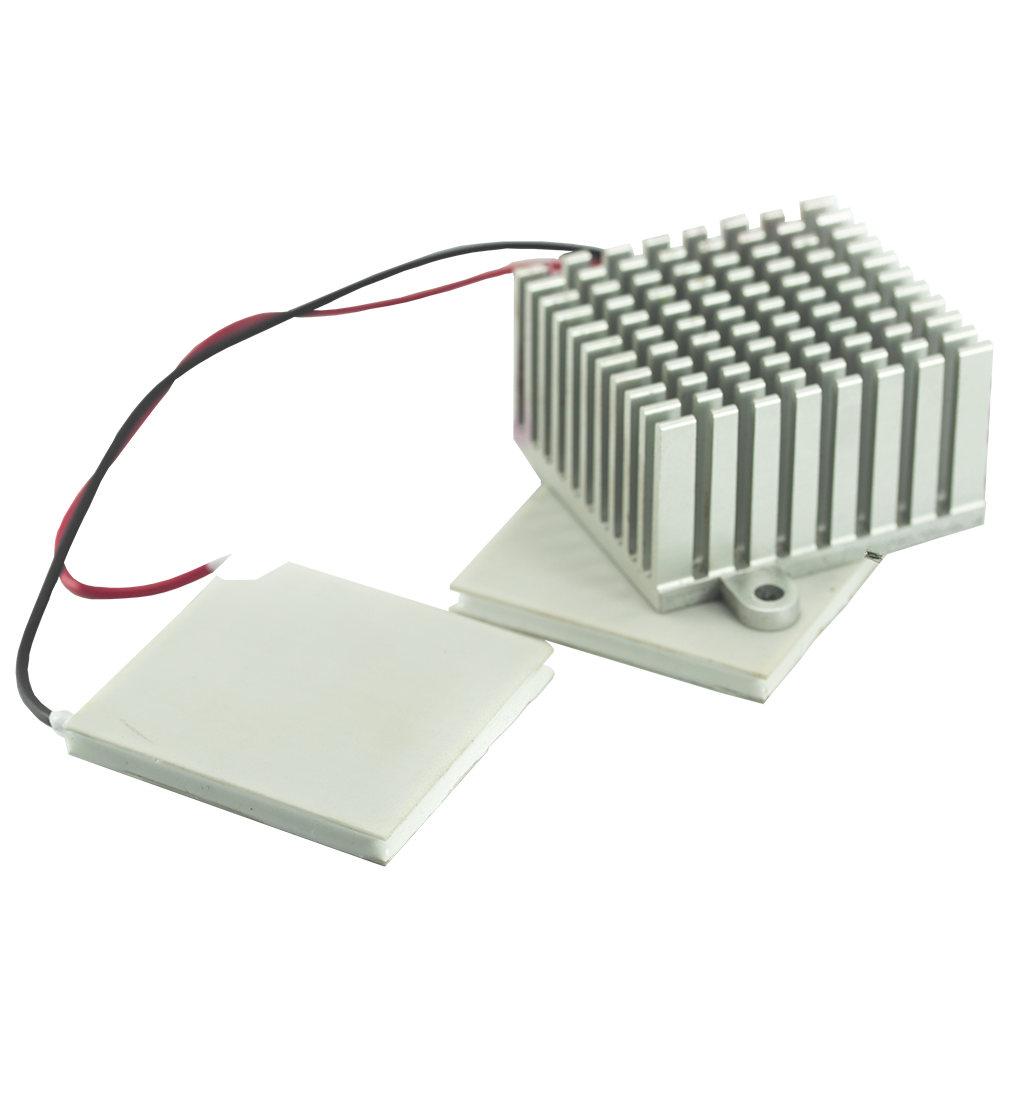

Cold plate technology is a method of thermal management that involves the use of a flat metal plate to transfer heat away from electronic components. The cold plate is typically made of aluminum or copper and has internal channels through which a cooling fluid, usually water, flows to absorb and dissipate heat. This process effectively cools the components and prevents overheating.

Benefits of Using Cold Plates for Thermal Management

Let's delve deeper into the specific advantages of cold plates and explore additional benefits:

Enhanced Performance and Reliability

- Increased System Uptime: Preventing overheating can significantly reduce system failures and downtime, resulting in increased productivity and cost savings.

- Enhanced Product Durability: Consistent temperature control protects sensitive components from thermal stress, leading to more durable and reliable products.

Environmental Benefits

- Reduced Energy Consumption: Efficient thermal management through cold plates can lead to lower energy consumption, contributing to a smaller environmental footprint.

- Extended Product Lifespan: By preventing premature component failure, cold plates help reduce electronic waste.

Applications of Cold Plates in Various Industries

Cold plates are extensively used in industries such as telecommunications, medical equipment, power electronics, and aerospace. They are employed in applications ranging from cooling high-power semiconductor devices to maintaining optimal operating temperatures for laser diodes and military electronics. Their versatility and effectiveness make them indispensable in ensuring the reliable performance and longevity of electronic systems.

Water-cooled systems play a crucial role in enhancing the efficiency of cold plates in various industries. Using water as a coolant, these systems can effectively dissipate heat from electronic components, ensuring optimal operating temperatures are maintained. This innovative approach not only improves the performance of cold plates but also contributes to electronic systems' overall reliability and longevity in demanding industrial applications.

The Role of Water Cooled Systems

How Water Cooled Systems Work with Cold Plates

Water cooled systems work with cold plates to efficiently manage thermal heat. These systems use water as a cooling medium to absorb heat from the cold plate, effectively dissipating it and maintaining optimal temperatures. Circulating water through the cold plate transfers heat away from the source, ensuring efficient thermal management.

Advantages of Water Cooled Systems in Thermal Management

The use of water cooled systems offers several advantages in thermal management. They provide superior heat dissipation compared to air cooling systems, making them ideal for high-performance applications. Additionally, water has a higher specific heat capacity than air, allowing it to carry away more heat energy from the cold plate. This results in more effective temperature control and enhanced overall performance.

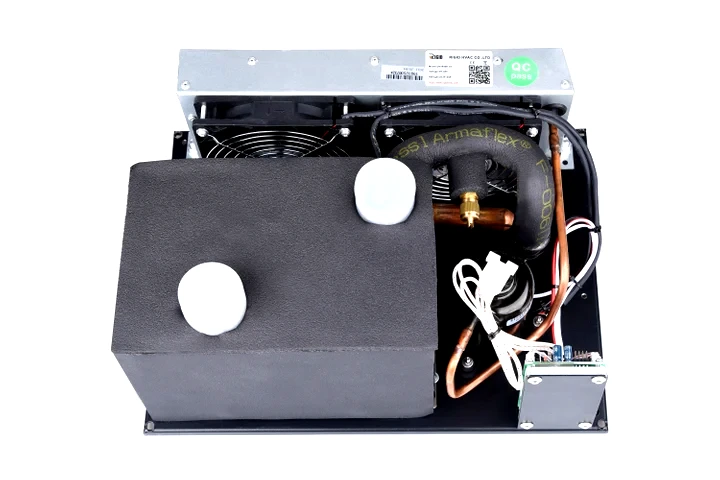

RIGID's Innovative Water Cooling System

RIGID has developed an innovative water cooling system that integrates seamlessly with cold plate technology. Our system is designed to optimize thermal management in various applications, offering reliable and efficient cooling solutions. Focusing on custom-made refrigeration solutions, RIGID's water cooling system is tailored to meet specific requirements and provide superior performance.

Liquid Cooling Technology

Liquid cooling technology is a revolutionary method of dissipating heat from electronic components using a liquid coolant, such as water or a water-based solution. This innovative approach offers superior thermal management to traditional air cooling systems, making it an ideal choice for high-performance applications.

Exploring Liquid Cooling Solutions

Liquid cooling solutions involve the circulation of a liquid coolant through cold plates or heat exchangers to absorb and transfer heat away from electronic devices. This process effectively reduces the temperature of the components, ensuring optimal performance and longevity. RIGID offers advanced liquid cooling solutions tailored to specific requirements, providing efficient thermal management for various industries.

Comparing Liquid Cooling with Traditional Air Cooling

Liquid cooling technology offers significantly higher heat dissipation efficiency and better temperature control than traditional air cooling methods. By utilizing cold plates and water-cooled systems, liquid cooling minimizes the risk of overheating and allows for more compact designs in electronic devices. RIGID's commitment to advancing refrigeration solutions includes incorporating liquid cooling for enhanced thermal management in modern applications.

Incorporating Liquid Cooling in High-Performance Applications

Implementing liquid cooling technology greatly benefits high-performance applications such as gaming PCs, data centers, and electric vehicles. By effectively managing heat through cold plates and water-cooled systems, these applications can operate at peak performance without the risk of thermal throttling or component damage. RIGID's expertise in custom-made refrigeration solutions extends to incorporating liquid cooling for optimal thermal management in diverse high-performance environments.

Advantages of Cold Plates in Thermal Management

1. Enhanced Heat Transfer with Cold Plate Technology

Cold plates are designed to efficiently transfer heat away from electronic components, ensuring optimal performance and longevity. Cold plates can effectively dissipate heat and maintain lower operating temperatures in electronic devices by utilizing a combination of materials with high thermal conductivity, such as copper or aluminum.

Cold plates are also designed with advanced fin and microchannel configurations to maximize surface area contact and improve heat dissipation. This allows for more efficient temperature control in electronic devices, reducing the risk of overheating and potential damage to sensitive components. By incorporating these innovative features, cold plate technology can significantly enhance electronic systems' overall performance and reliability.

2. Efficient Temperature Control in Electronic Devices

Water cooled systems and liquid cooling technology are integrated with cold plates to provide precise temperature control for electronic devices. This ensures that sensitive components remain within their specified operating temperature range, preventing overheating and potential damage. RIGID's innovative water cooling system is precisely engineered to work seamlessly with cold plate technology, offering reliable thermal management solutions.

In addition to providing precise temperature control, RIGID's water cooled systems and liquid cooling technology also offer energy efficiency, reducing the overall power consumption of electronic devices. By effectively dissipating heat from sensitive components, these innovative solutions contribute to the longevity and reliability of electronic devices, ultimately saving on maintenance and replacement costs. With RIGID's custom-made refrigeration solutions, businesses can optimize the performance of their electronic equipment while minimizing environmental impact.

Custom-Made Refrigeration Solutions by RIGID

RIGID specializes in providing custom-made refrigeration solutions tailored to clients' specific needs across various industries. Our expertise in cold plate technology, water cooled systems, and liquid cooling enables us to deliver efficient and cost-effective thermal management solutions that enhance the performance of electronic devices while extending their lifespan.

Our team at RIGID works closely with clients to understand their unique requirements and challenges, allowing us to develop tailored refrigeration solutions that meet their specific needs. Whether it's designing a custom cold plate system for a medical device or implementing a water-cooled solution for an industrial application, we have the expertise and flexibility to deliver the right solution. By prioritizing efficiency and cost-effectiveness, we ensure that our thermal management solutions enhance device performance and contribute to long-term reliability.

Implementing Thermal Management Solutions

Tailored Cold Plate Solutions for Specific Requirements

At RIGID, we understand that each industry and application have unique thermal management needs. That's why we offer tailored cold plate solutions to meet specific requirements. Whether for electronics, medical equipment, or industrial machinery, our team works closely with clients to design and manufacture cold plates that deliver optimal cooling performance. By customizing our cold plate solutions, we ensure that our clients' systems operate at peak efficiency, increasing productivity and cost savings. Our expertise in thermal management allows us to address even the most complex cooling challenges, providing innovative solutions that give our clients a competitive edge in their respective industries.

Boosting Competitiveness through Effective Thermal Management

Effective thermal management is crucial for boosting competitiveness in today's fast-paced market. By implementing advanced cold plate technology, water cooled systems, and liquid cooling solutions, businesses can enhance the performance and reliability of their products. RIGID's innovative refrigeration solutions play a key role in helping clients stay ahead of the competition.

In addition to providing cutting-edge refrigeration solutions, RIGID also offers custom-made options tailored to each client's specific needs. This personalized approach ensures businesses can optimize their thermal management systems to maximize efficiency and performance. By collaborating with RIGID for custom-made refrigeration solutions, companies can gain a competitive edge by having a system designed specifically for their unique requirements.

Collaborating with RIGID for Custom-Made Refrigeration Solutions

When it comes to custom-made refrigeration solutions, RIGID is the go-to partner for businesses across various industries. Our expertise in cold plate technology, water cooled systems, and liquid cooling allows us to collaborate with clients and develop tailored refrigeration solutions that align with their needs and budget constraints.

In addition to our technical expertise, RIGID also prides itself on our commitment to customer service. Our team of experienced professionals works closely with clients to understand their unique refrigeration needs and provide personalized support every step of the way. From initial consultation to installation and ongoing maintenance, we are dedicated to delivering our clients a seamless and stress-free experience.

Embracing Water Cooled, Liquid Cooling, and Cold Plate Technology

Efficient thermal management is crucial in various industries, and RIGID understands this. With our commitment to providing custom-made refrigeration solutions, we aim to address the specific needs of our clients and help them stay competitive in their respective fields. By embracing water-cooled, liquid cooling, and cold plate technology, we ensure that our clients have access to cutting-edge thermal management solutions.

The Importance of Efficient Thermal Management

Efficient thermal management ensures the longevity and optimal performance of electronic devices and industrial equipment. By utilizing advanced technologies such as cold plates, water cooled systems, and liquid cooling, businesses can effectively regulate temperatures and prevent overheating issues.

RIGID's Commitment to Custom-Made Refrigeration Solutions

RIGID may not be a century-old company, but we are dedicated to staying ahead of the curve when providing innovative refrigeration solutions. Our focus on understanding clients' budgets allows us to offer tailored products that meet their specific requirements while boosting their market competitiveness.

As a forward-thinking company, RIGID embraces the latest advancements in thermal management technology. Our range of products includes water cooled systems, liquid cooling solutions, and custom-made cold plates designed for high-performance applications across various industries.