Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of cooling systems, the refrigerant oil separator plays a pivotal role. As HVAC technologies evolve, the need for effective management of refrigerant and oil mixtures has become increasingly critical. Understanding how does a refrigerant oil separator work is essential for optimizing system performance and ensuring longevity.

The Need for Refrigerant Oil Separators

Refrigerants are crucial for effective cooling, but they often carry oil that can lead to inefficiencies if not properly managed. This is where the refrigerant oil separator comes into play, ensuring that oil is removed from the refrigerant flow before it returns to the compressor. Without these separators, systems would suffer from contamination, leading to reduced efficiency and potential damage.

Importance in Cooling Systems

The importance of refrigerant oil separators in cooling systems cannot be overstated; they enhance overall system efficiency while preventing costly breakdowns. By effectively removing excess oil from the refrigerant cycle, these devices help maintain optimal operating conditions within HVAC units and chillers alike. Consequently, understanding what is the function of the oil separator becomes vital for anyone involved in maintaining or designing cooling systems.

Overview of Key Functions

At its core, a refrigerant oil separator serves several key functions: it prevents contamination by separating oil from refrigerants, enhances system efficiency through improved heat transfer capabilities, and extends equipment lifespan by reducing wear on components. Additionally, knowing what is the oil separator in a chiller helps clarify its role as an integral component that directly impacts performance metrics such as energy consumption and thermal output. Lastly, exploring how does an oily separator work reveals mechanisms that ensure optimal operation and reliability across various applications.

What is a Refrigerant Oil Separator?

A refrigerant oil separator is a crucial component in various cooling systems, designed to ensure the efficient operation of HVAC units by separating oil from refrigerant. By doing so, it prevents the contamination of refrigerants and enhances overall system performance. Understanding what a refrigerant oil separator is and how it functions can help you appreciate its importance in maintaining optimal cooling efficiency.

Definition and Components

At its core, a refrigerant oil separator is a device that separates lubricating oil from the refrigerant gas in cooling systems. Typically, it consists of several key components including an inlet for the mixture of refrigerant and oil, a separation chamber where centrifugal forces work their magic, and an outlet for the purified refrigerant. This ingenious design allows for continuous operation without significant interruptions, ensuring that your cooling system runs smoothly.

Types of Refrigerant Oil Separators

There are various types of refrigerant oil separators available on the market today, each tailored to specific applications and needs. The most common types include centrifugal separators, which leverage high-speed rotation to separate oil from gas effectively; gravity separators that rely on density differences; and coalescing separators that use filter media to collect droplets of oil. Understanding these different types can help you determine which one best suits your system's requirements.

Common Applications in HVAC

Refrigerant oil separators are widely used across numerous applications in HVAC systems, particularly in chillers and large commercial refrigeration units. They play an essential role not only in preventing contamination but also in enhancing energy efficiency—an increasingly critical factor as energy costs rise globally. Additionally, you'll find these separators employed in industrial refrigeration processes where maintaining optimal temperatures is vital for product quality and safety.

How Does a Refrigerant Oil Separator Work?

Understanding how a refrigerant oil separator works is essential for anyone involved in HVAC systems. The process of separating oil from refrigerant is crucial to maintaining system efficiency and preventing damage. By effectively removing the lubricant, these separators ensure that the cooling systems operate smoothly and efficiently.

Understanding the Separation Process

The separation process begins when the refrigerant-oil mixture enters the separator. Inside, the design facilitates gravity-driven separation, where heavier oil particles settle at the bottom while lighter refrigerant rises to the top. This fundamental mechanism is vital for answering questions like What is the function of the oil separator? as it directly influences performance and longevity.

The Role of Centrifugal Forces

Centrifugal forces play a significant role in enhancing the efficiency of a refrigerant oil separator. As the mixture flows through, it encounters rapid rotational motion that pushes heavier oil outward, further aiding in its separation from lighter refrigerants. This dynamic interaction not only improves how does an oily separator work but also optimizes overall system performance.

Interaction with Refrigerant Fluids

The interaction between refrigerant fluids and separated oil is critical for understanding what is the oil separator in a chiller? Once separated, lubricating oils are routed back into key components of cooling systems to ensure smooth operation without contamination risks. This seamless integration highlights why regular maintenance is essential; neglecting this aspect can lead to inefficiencies or even system failures over time.

What is the Function of the Oil Separator?

The refrigerant oil separator plays a crucial role in ensuring that cooling systems operate efficiently and effectively. By separating oil from refrigerant, it prevents potential contamination that could compromise system performance. In essence, the oil separator is a guardian of the system's integrity, keeping everything running smoothly.

Preventing Oil Contamination in Systems

One of the primary functions of a refrigerant oil separator is to prevent oil contamination within HVAC systems. When refrigerants cycle through these systems, they can carry small amounts of oil with them, which can lead to buildup and inefficiencies over time. By effectively removing this oil from the refrigerant before it circulates back into critical components, the separator ensures that each part operates without unnecessary strain or wear.

In addition to maintaining cleanliness within the system, preventing oil contamination helps avoid issues like compressor failure and reduced cooling capacity. Without an efficient separation process, contaminants could accumulate and lead to costly repairs or replacements down the line. Thus, understanding how does a refrigerant oil separator work becomes essential for anyone involved in HVAC maintenance and operation.

Enhancing System Efficiency

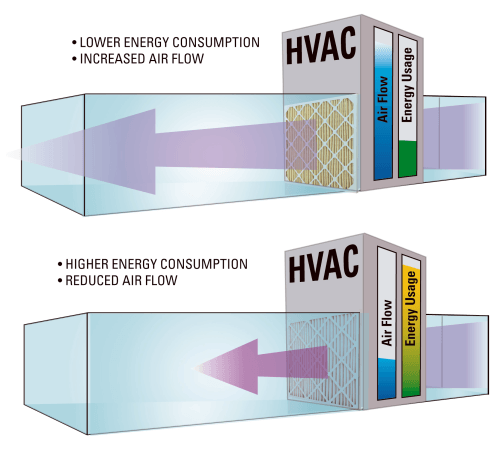

Another vital function of an oil separator is enhancing overall system efficiency. When excess oil remains mixed with refrigerants, it can hinder heat transfer processes essential for effective cooling performance. A well-functioning refrigerant oil separator ensures that only clean refrigerants circulate through evaporators and condensers, maximizing their ability to absorb and release heat.

Moreover, by reducing the amount of excess lubricant in circulation, these separators contribute to lower energy consumption levels across HVAC systems. This not only leads to cost savings on energy bills but also promotes environmental sustainability by minimizing wasteful energy use. Therefore, understanding what is the function of the oil separator can help facility managers make informed decisions about their cooling technology investments.

Extending Equipment Lifespan

Lastly, a properly functioning refrigerant oil separator significantly extends equipment lifespan across cooling systems like chillers and mini compressors. By preventing harmful contaminants from entering sensitive components such as compressors or expansion valves, these separators mitigate wear and tear on expensive machinery over time.

Regularly maintaining this component ensures that systems remain efficient throughout their operational life cycle—reducing downtime due to repairs or replacements caused by contaminated oils or lubricants clogging critical pathways within equipment assemblies. When considering what is the oil separator in a chiller specifically highlights its importance; without it functioning optimally, even state-of-the-art chillers may underperform or fail prematurely.

In conclusion, recognizing how does an oily separator work reveals its multifaceted benefits: preventing contamination enhances efficiency while extending equipment lifespan—all vital for any successful HVAC operation looking toward future growth!

What is the Oil Separator in a Chiller?

In the realm of chiller systems, the oil separator plays a pivotal role in ensuring optimal performance and longevity. Understanding what is the oil separator in a chiller can help clarify its significance as an integral component that manages refrigerant and oil separation efficiently. This not only enhances system reliability but also contributes to energy savings over time.

Integral Component of Chiller Systems

The refrigerant oil separator is an essential part of any chiller system, tasked with maintaining the balance between refrigerant and lubricant oils. Without it, excess oil could circulate through the system, leading to inefficiencies and potential damage to critical components. By effectively removing oil from the refrigerant before it returns to the compressor, this separator ensures smooth operation and maximizes cooling efficiency.

Differences Between Oil Separators and Other Components

When considering how does a refrigerant oil separator work compared to other components, it's important to note its unique function within the chiller system. Unlike filters that simply trap particles or debris, an oil separator actively separates liquid oil from vaporized refrigerant using centrifugal forces or gravity-based methods. This distinction means that while other components may enhance performance indirectly, the refrigerant oil separator directly impacts how well a chiller operates.

Impact on Chiller Performance

The impact of an effective refrigerant oil separator on chiller performance cannot be overstated; it plays a crucial role in maintaining system efficiency and preventing unnecessary wear on equipment. By regularly removing excess oil from the refrigerant cycle, these separators ensure that compressors are lubricated properly without being overwhelmed by liquid oils that could lead to flooding or inefficiency. Ultimately, understanding what is the function of the oil separator helps illustrate its importance in extending equipment lifespan and enhancing overall cooling capacity.

How Does an Oily Separator Work?

Understanding how an oily separator works is crucial for maintaining efficient cooling systems. It plays a vital role in ensuring that the refrigerant oil separator effectively separates oil from refrigerant, thereby preventing contamination and enhancing system performance. This section will delve into the mechanisms of oil recovery, the lifecycle of refrigerant and oil, and the importance of regular maintenance.

Mechanisms of Oil Recovery

The primary function of a refrigerant oil separator is to recover lubricating oil that circulates with the refrigerant in cooling systems. The process starts when the mixture enters the separator; centrifugal forces are utilized to separate heavier oil particles from lighter refrigerants. As a result, this mechanism allows for efficient recovery of oil which can then be redirected back into the compressor, ensuring optimal lubrication and reducing wear on system components.

Lifecycle of Refrigerant and Oil

The lifecycle of refrigerant and oil in a cooling system is intricately linked to how does a refrigerant oil separator work? The refrigerant absorbs heat from its environment while circulating through various components, but it also carries some lubricant with it. Over time, this can lead to an imbalance if not managed properly; hence, understanding what is the function of the oil separator becomes essential for maintaining equilibrium within chiller systems or any refrigeration setup.

Importance of Regular Maintenance

Regular maintenance is key to ensuring that an oily separator operates at peak efficiency. Neglecting this aspect can lead to accumulated contaminants in both the refrigerant and lubricating oils, ultimately compromising system performance. By scheduling routine checks on what is the oil separator in a chiller or other cooling devices, users can enhance longevity and reliability while avoiding costly repairs down the line.

RIGID's Innovations in Refrigerant Oil Separators

RIGID is at the forefront of innovation in refrigerant oil separators, particularly within the realm of mini compressors. By integrating advanced technologies into their designs, RIGID enhances the efficiency and performance of cooling systems. This commitment to innovation ensures that their refrigerant oil separators not only meet but exceed industry standards.

Advanced Technologies in Mini Compressors

When we ask, How does a refrigerant oil separator work? RIGID's advanced mini compressors provide a clear answer with their cutting-edge technology. These compressors utilize sophisticated separation mechanisms that enhance the effectiveness of oil recovery while minimizing energy consumption. The result is a seamless integration of the refrigerant oil separator with other system components, ensuring optimal performance in various applications.

In addition to efficiency, these mini compressors are designed for compactness without sacrificing power or reliability. This allows for versatile installations across different environments, from residential units to commercial applications. By focusing on advanced technologies, RIGID demonstrates how modern engineering can redefine what we expect from refrigerant oil separators and cooling systems as a whole.

Custom Solutions for Specific Needs

Understanding that one size does not fit all, RIGID specializes in providing custom solutions tailored to clients' specific needs regarding refrigerant oil separators. Whether it's addressing unique operational challenges or optimizing system performance, RIGID collaborates closely with customers to develop bespoke refrigeration solutions. This approach not only answers questions like What is the function of the oil separator? but also ensures that each solution meets precise requirements effectively.

RIGID’s flexibility extends beyond just design; they also consider budgetary constraints while delivering top-notch quality and functionality. Their team works diligently to craft solutions that enhance competitiveness in various markets by ensuring systems run smoothly and efficiently. With an emphasis on customization, clients can trust that their specific needs will be met without compromise.

Commitment to Quality and Customer Satisfaction

At RIGID, quality isn’t just a buzzword; it’s a core principle guiding every aspect of their operations concerning refrigerant oil separators and related technologies. Their commitment to excellence means rigorous testing and quality assurance measures are implemented throughout production processes—ensuring reliability you can count on when asking What is the oil separator in a chiller?

Customer satisfaction is paramount at RIGID; they prioritize open communication and feedback throughout projects to ensure expectations are met or exceeded every time. Regular maintenance advice is also provided so clients understand how does an oily separator work optimally over time—extending equipment lifespan while maintaining high operational efficiency.

By focusing on both quality and customer service, RIGID has established itself as a trusted partner in micro cooling technology—making significant strides toward defining future industry standards.

Conclusion

In summary, refrigerant oil separators play a crucial role in maintaining the efficiency and longevity of cooling systems. Understanding how does a refrigerant oil separator work is essential for anyone involved in HVAC or refrigeration applications. With their ability to prevent oil contamination and enhance system performance, these devices are integral to modern cooling technology.

Key Takeaways on Oil Separators

The primary function of the oil separator is to ensure that refrigerant systems operate smoothly by removing excess oil from the refrigerant. What is the function of the oil separator? It's all about protecting your system from potential damage caused by oil build-up, which can lead to inefficiency and costly repairs. Additionally, knowing what is the oil separator in a chiller helps clarify its importance as an integral component that significantly impacts overall performance.

The Future of Cooling Technology

As technology advances, so too will the capabilities of refrigerant oil separators. Innovations such as smart monitoring systems and enhanced materials will improve how does an oily separator work, allowing for more precise control over separation processes. The future also holds promise for integrating these separators with other components in cooling systems to create even more efficient and sustainable solutions.

Why Choose RIGID for Your Cooling Needs

RIGID stands out as a leader in mini compressor innovation with a strong commitment to quality and customer satisfaction. Their expertise ensures that you receive cutting-edge solutions tailored specifically to your requirements, whether it's about understanding how does a refrigerant oil separator fit into your setup or needing custom designs for unique applications. When it comes to micro refrigeration & air conditioning applications, RIGID offers superior design and reliability that you can trust.