Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of heating, ventilation, and air conditioning (HVAC), the rotary compressor plays a pivotal role in ensuring efficient climate control. Understanding what a rotary compressor in HVAC is can help consumers make informed choices about their cooling systems. With its unique design and functionality, the rotary compressor stands out among traditional options, making it essential for modern HVAC applications.

Importance of Rotary Compressor in HVAC

The importance of rotary compressors in HVAC systems cannot be overstated. These compressors are known for their reliability and efficiency, which contribute significantly to the overall performance of an HVAC system. As energy costs rise and environmental concerns grow, the demand for high-efficiency solutions like rotary compressors continues to increase.

Key Features of Rotary Compressors

Rotary compressors boast several key features that set them apart from other types of compressors. They are compact in design, which allows for easier installation in various settings while maximizing space efficiency. Additionally, their quieter operation makes them ideal for residential applications where noise reduction is a priority.

Overview of the HVAC System

An HVAC system comprises various components working together to maintain indoor comfort levels through heating and cooling processes. The rotary compressor serves as the heart of this system by compressing refrigerant gas and facilitating heat exchange processes essential for temperature regulation. Understanding how these components interact provides insight into why choosing the right type of compressor—like a rotary or swing model—is crucial for optimal system performance.

What is a Rotary Compressor in HVAC?

When discussing HVAC systems, the term rotary compressor frequently arises due to its pivotal role in maintaining efficient climate control. A rotary compressor in HVAC is a type of mechanical device that compresses refrigerant gas for cooling and heating purposes. It’s essential to understand what a rotary compressor is and how it functions within an HVAC system to appreciate its advantages.

Definition and Functionality

A rotary compressor in HVAC refers to a specific design of compressors that utilizes rotating elements to compress refrigerant gases. Unlike traditional reciprocating compressors, which use pistons, rotary compressors employ either rolling or sliding vanes to achieve compression. This unique functionality allows for smoother operation, reduced noise levels, and increased durability, making it a popular choice among HVAC professionals.

How It Works in HVAC Systems

In an HVAC system, the rotary compressor operates by drawing low-pressure refrigerant gas from the evaporator coil and compressing it into high-pressure gas before sending it to the condenser coil. This process involves rotating blades or vanes that trap the refrigerant gas within chambers, effectively reducing its volume and increasing pressure simultaneously. The efficiency of this operation directly contributes to the overall performance of an HVAC system.

Real-World Applications

Rotary compressors are commonly found in various applications ranging from residential air conditioning units to commercial refrigeration systems. Their compact size makes them ideal for space-constrained environments such as small apartments or mobile cooling solutions like those offered by RIGID—a leader in mini compressor innovation based in China. Beyond just air conditioning, these compressors are also utilized in heat pumps and chillers, showcasing their versatility across different sectors.

Advantages of Rotary Compressors

When it comes to HVAC systems, one of the standout components is the rotary compressor. This type of compressor offers numerous advantages that enhance both efficiency and performance in heating, ventilation, and air conditioning applications. As we dive deeper into the benefits, it’s essential to understand why a rotary compressor is often favored over traditional models.

Efficiency and Performance

The efficiency and performance of a rotary compressor in HVAC systems are noteworthy features that set it apart from its counterparts. Unlike reciprocating compressors, rotary compressors operate smoothly with fewer moving parts, which minimizes wear and tear while maximizing operational efficiency. This design not only ensures a consistent cooling output but also contributes to longer service life—making it an attractive option for both residential and commercial applications.

Moreover, when you ask yourself, What is a rotary compressor in HVAC? the answer lies in its ability to handle varying loads effectively. Rotary compressors adjust their capacity based on demand without compromising on performance or energy consumption. This adaptability translates into better temperature control and enhanced comfort levels within indoor environments.

Energy Savings Over Traditional Compressors

One of the most compelling reasons to choose a rotary compressor is its potential for significant energy savings compared to traditional compressors. The efficient operation means that less electricity is required to achieve the same cooling effect—an essential consideration for environmentally conscious consumers looking to reduce their carbon footprint.

In fact, many users have reported lower utility bills after switching from reciprocating units to rotary compressors, leading them to ponder: Is a rotary compressor better than a normal compressor? The answer tends to lean towards yes, especially when considering long-term operational costs alongside initial investments.

Additionally, advancements in technology have allowed modern rotary compressors to integrate variable speed drives (VSD). These innovations further enhance energy efficiency by allowing the unit to modulate its speed according to real-time cooling needs rather than running at full capacity all the time.

Compact Design Benefits

Another advantage of using a rotary compressor in HVAC systems is its compact design. Unlike larger traditional compressors that require significant space for installation and operation, rotary models are generally more streamlined and smaller—perfect for tight spaces or mobile applications like those offered by RIGID's mini compressor technologies. Their size does not compromise functionality; rather, it allows for versatile installation options without sacrificing performance.

This compactness also makes maintenance easier since technicians can access these units without navigating around bulky equipment—a common frustration with larger models. Furthermore, as we consider questions like Which compressor is better, rotary or swing?, it's clear that the space-saving nature of rotary designs provides practical benefits beyond just aesthetics.

In summary, whether you're evaluating energy savings or seeking efficient performance within limited spaces, choosing a rotary compressor can offer distinct advantages over other types available on the market today.

Is a Rotary Compressor Better Than a Normal Compressor?

When evaluating whether a rotary compressor is better than a normal compressor, particularly in HVAC systems, it’s essential to consider several factors. The comparison often centers around efficiency, performance, and user satisfaction. By examining these aspects, we can determine the advantages and disadvantages of rotary compressors in relation to traditional options.

Comparison With Reciprocating Compressors

Reciprocating compressors have long been the go-to choice for many HVAC applications due to their robust design and reliability. However, when we ask Is a rotary compressor better than a normal compressor?, rotary compressors start to shine with their superior efficiency and quieter operation. Unlike reciprocating models that rely on pistons moving back and forth, rotary compressors use rotating elements that result in smoother operation and less vibration.

One significant advantage of rotary compressors is their compact size, making them ideal for space-constrained installations where every inch matters. Additionally, the continuous flow of refrigerant in rotary systems minimizes pressure fluctuations compared to reciprocating compressors. This consistency leads to improved energy efficiency—an important factor for anyone considering what is a rotary compressor in HVAC applications.

Performance Under Varying Conditions

Performance can vary significantly under different operating conditions between these two types of compressors. Rotary compressors tend to maintain consistent performance even as environmental variables change—like temperature or humidity levels—making them reliable choices for diverse climates. In contrast, reciprocating compressors may struggle under extreme conditions due to their mechanical complexity.

Furthermore, when considering What are the disadvantages of rotary compressors?, it’s crucial to note that while they excel in many scenarios, they may not be as effective in high-load situations where reciprocating units might outperform them. Despite this limitation, many users find that the benefits of using a rotary compressor outweigh potential shortcomings for standard HVAC applications. This reliability under varying conditions makes them increasingly popular among both manufacturers and consumers alike.

User Experience and Feedback

User experience plays an integral role in determining whether a rotary compressor is preferable over traditional options like reciprocating models or swing compressors. Many users report higher satisfaction levels with the quieter operation and lower maintenance requirements associated with rotary systems compared to their counterparts. The ease of installation also contributes positively to user feedback; fewer components mean quicker setups.

However, some users express concerns regarding specific limitations of rotary technology—particularly regarding its performance at extreme temperatures or high-capacity demands where traditional systems might excel more effectively. Ultimately, consumer feedback suggests that while both types have their merits and drawbacks—including Which compressor is better: rotary or swing?—the choice often comes down to specific application needs and personal preferences regarding efficiency versus power demands.

What are the Disadvantages of Rotary Compressors?

While rotary compressors are popular in HVAC applications, they do come with their own set of disadvantages. Understanding these limitations is crucial for anyone considering What is a rotary compressor in HVAC? or weighing whether Is a rotary compressor better than a normal compressor? In this section, we will explore common issues, maintenance considerations, and cost implications associated with rotary compressors.

Common Issues and Limitations

One of the primary concerns with rotary compressors is their sensitivity to operating conditions. They tend to perform best within a specific range of temperatures and pressures; deviations can lead to inefficiencies or even failure. Additionally, while they generally operate quietly, some models may produce vibrations that can affect nearby components in an HVAC system.

Another limitation is their performance under extreme loads or prolonged use. Unlike reciprocating compressors that can handle high-pressure scenarios better, rotary compressors may struggle when pushed beyond their optimal limits. This raises questions about durability and reliability over time—factors that anyone considering What are the disadvantages of rotary compressors? should keep in mind.

Maintenance and Repair Considerations

When it comes to maintenance, rotary compressors require specific attention to ensure optimal performance. While they often have fewer moving parts than traditional options, which might suggest lower maintenance needs, they still require regular checks for oil levels and refrigerant quality. Neglecting these aspects could lead to more significant issues down the line.

Repairing a rotary compressor can also be more complicated compared to other types like reciprocating models. Specialized knowledge may be required for troubleshooting and repairs due to unique design features—something important for those pondering Which compressor is better, rotary or swing? It's advisable for users to work closely with qualified technicians familiar with these systems.

Cost Implications for Consumers

Cost is another critical factor when evaluating the viability of a rotary compressor in HVAC systems. Although initial purchase prices might be competitive compared to other types of compressors, potential long-term costs could add up if frequent repairs or replacements become necessary due to operational limitations or maintenance oversights.

Moreover, energy efficiency claims must be scrutinized; while many manufacturers tout energy savings over traditional options like reciprocating compressors, real-world performance can vary significantly based on usage patterns and environmental factors. Therefore, consumers should carefully assess whether the benefits truly outweigh the costs before committing fully—especially when asking themselves Is a rotary compressor better than a normal compressor?

Which Compressor is Better, Rotary or Swing?

When it comes to choosing the right compressor for HVAC systems, many people find themselves weighing the options between rotary compressors and swing compressors. Each type has its unique features and applications that cater to different needs in heating, ventilation, and air conditioning. Understanding these differences can help users make informed decisions based on efficiency, performance, and cost-effectiveness.

Understanding Swing Compressors

Swing compressors operate using a different mechanism compared to rotary compressor HVAC systems. They utilize a swinging motion of a piston to compress refrigerant gases, which allows for effective cooling or heating in various environments. While they provide reliable performance, their design tends to be bulkier and may not offer the same level of compactness as rotary compressors.

Benefits and Drawbacks of Both Types

Both rotary and swing compressors have their advantages and disadvantages worth considering. Rotary compressors are known for their compact design, energy efficiency, and quieter operation—making them ideal for residential HVAC systems where space is limited. In contrast, swing compressors can handle larger volumes of refrigerant but may require more maintenance due to their mechanical complexity; thus raising questions such as What are the disadvantages of rotary compressors? when comparing longevity and upkeep.

Ideal Use Cases for Each

Choosing between a rotary compressor HVAC system or a swing compressor often depends on specific application requirements. Rotary compressors excel in smaller spaces where energy efficiency is paramount—like apartments or small offices—while swing compressors might be better suited for larger industrial settings requiring high-capacity cooling solutions. Ultimately, understanding Is a rotary compressor better than a normal compressor? hinges on evaluating individual needs against the strengths of each option.

Innovations in Rotary Compressors by RIGID

In the rapidly evolving world of HVAC technology, RIGID stands out as a leader in mini compressor innovations. Their commitment to developing cutting-edge rotary compressors has transformed how we think about compact cooling systems. With a focus on efficiency and performance, RIGID is redefining what we expect from rotary compressor HVAC solutions.

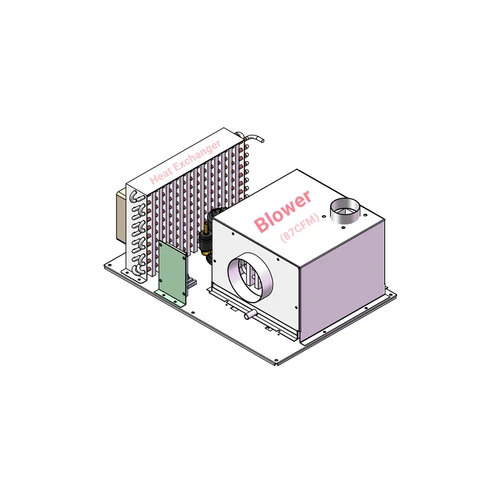

Overview of RIGID’s Mini Compressor Technologies

RIGID's mini compressor technologies are designed to deliver exceptional performance while occupying minimal space, making them ideal for various applications. These rotary compressors are engineered for versatility, catering to needs in mobile and compact cooling systems. By integrating advanced materials and innovative designs, RIGID ensures that their products not only meet but exceed industry standards.

Advancements in Energy Efficiency

Energy efficiency is a critical consideration when evaluating What is a rotary compressor in HVAC? RIGID has made significant strides in this area by incorporating smart technologies that optimize energy consumption without sacrificing performance. Their latest models demonstrate impressive reductions in energy usage compared to traditional compressors, which directly contributes to lower operating costs for consumers—an essential factor when considering Is a rotary compressor better than a normal compressor?

Custom Solutions for HVAC Applications

Understanding that one size does not fit all, RIGID offers custom solutions tailored specifically for diverse HVAC applications. Whether it's mini water chillers or micro DC air conditioning units, they collaborate closely with clients to develop systems that align with unique operational requirements and budget constraints. This level of customization helps address some of the common queries regarding What are the disadvantages of rotary compressors? by mitigating limitations through innovative engineering.

Conclusion

In summary, rotary compressors play a pivotal role in HVAC systems, providing efficient and reliable cooling solutions. Understanding What is a rotary compressor in HVAC? reveals its significance in modern air conditioning technology. With their compact design and superior performance, rotary compressors are increasingly favored over traditional options.

Recap of Rotary Compressor Benefits

Rotary compressors offer numerous advantages that make them a popular choice in HVAC applications. Their efficiency translates to significant energy savings, making them an environmentally friendly option for consumers and businesses alike. Additionally, the compact design of rotary compressors allows for easy installation and versatility in various settings, proving that they are not just functional but also space-efficient.

Final Thoughts on Compressor Choices

When considering Is a rotary compressor better than a normal compressor?, it’s essential to evaluate your specific needs and circumstances. While rotary compressors excel in efficiency and compactness, traditional options may still hold merit depending on the application. Ultimately, the choice between different types of compressors—be it rotary or swing—should be guided by performance requirements and budget considerations.

Future Trends in HVAC Technology

As we look ahead, innovations from companies like RIGID are set to redefine the landscape of mini compressor technologies within HVAC systems. RIGID's commitment to capturing new technologies ensures that advancements in energy efficiency will continue to emerge. The future will likely see more customized solutions tailored to meet specific client needs while addressing concerns such as What are the disadvantages of rotary compressors?—ultimately leading to smarter and more sustainable cooling systems.