Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

Understanding Ice Machine Compressors

An ice machine compressor serves as the heart of your refrigeration system, compressing refrigerant gas and circulating it throughout the unit to facilitate cooling. Essentially, it transforms low-pressure gas into high-pressure gas, allowing for efficient heat exchange and ultimately producing that much-needed ice. Knowing how to tell if an ice machine compressor is bad could save you from costly downtime and repairs when you need your equipment most.

Exploring Common Issues with Compressors

Despite their robust design, compressors can encounter various issues that may hinder performance or even lead to failure. One common concern among users is whether it's normal for a compressor to ice up; understanding these symptoms can be crucial for timely intervention. By identifying these problems early on—like strange noises or insufficient ice production—you can take proactive measures before they escalate into more serious complications.

The Importance of Ice Machine Maintenance

Regular maintenance of your ice machine compressor cannot be overstated; it's essential for prolonging its lifespan and maintaining optimal efficiency. Routine checks can help identify potential issues before they become major headaches, reducing the likelihood of needing an expensive ice machine compressor replacement down the line. By prioritizing maintenance, you're not just protecting your investment but also ensuring that you'll always have reliable access to fresh ice when you need it most.

What is an Ice Machine Compressor?

An ice machine compressor is a crucial component that plays a vital role in the ice-making process. It essentially compresses refrigerant gas, raising its temperature and pressure before sending it to the condenser, where it cools down and transforms into liquid. This cycle is what enables your ice machine to produce the frosty cubes that keep your drinks chilled.

Basic Functionality of Compressors

To understand what is a compressor in an ice machine, think of it as the heart of the system. The compressor circulates refrigerant through the evaporator and condenser coils, facilitating heat exchange that ultimately leads to ice production. If you ever find yourself asking, Why is the compressor not working on my ice machine? it's likely due to issues with this essential component failing to perform its function effectively.

The basic functionality relies on converting low-pressure refrigerant gas into high-pressure gas before it moves into the condenser. When everything works smoothly, you'll enjoy a steady supply of ice; however, any hiccup can disrupt this process significantly. Regular maintenance can prevent these disruptions and ensure your ice machine compressor operates at peak efficiency.

Types of Ice Machine Compressors

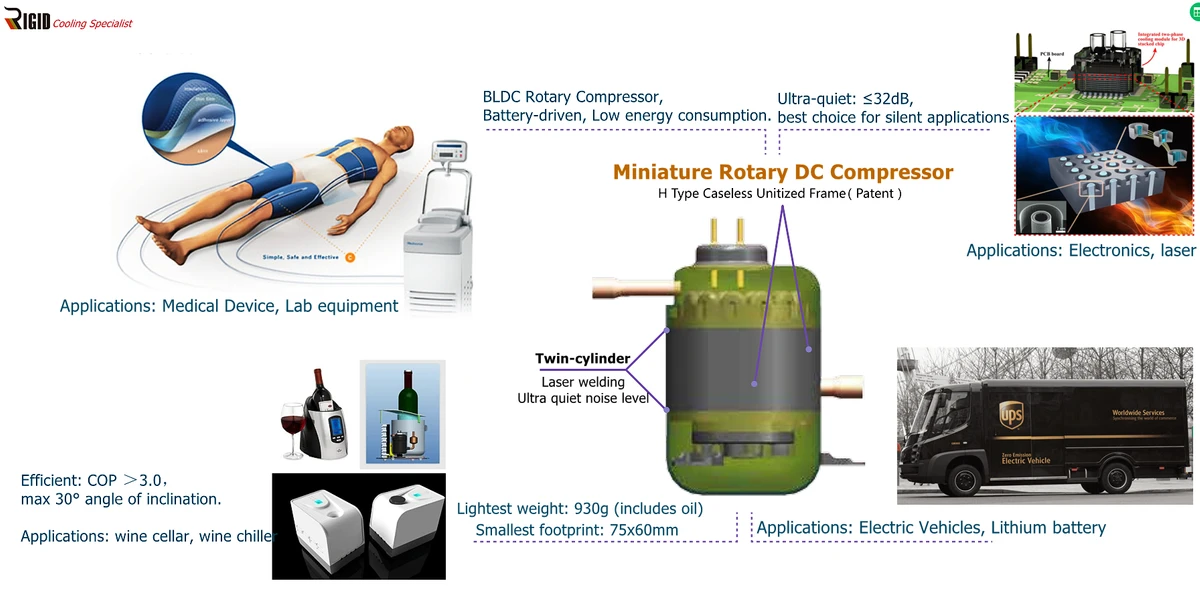

There are several types of compressors used in ice machines, each with its own unique features and benefits. The most common types include reciprocating compressors, scroll compressors, and rotary compressors; each type serves different needs based on design and application requirements. Understanding these differences can help you make informed decisions about which type best suits your needs.

Reciprocating compressors are popular for their reliability but can be noisy; scroll compressors offer quieter operation with fewer moving parts but may come at a higher price point—often leading people to inquire about Ice Machine Compressor Price variations among different models. Rotary compressors are compact and efficient but may not be suitable for all applications.

Choosing the right type of compressor also impacts how efficiently your machine produces ice—if you're considering an upgrade or replacement, knowing which type will work best for your specific setup can save you both time and money in the long run.

How Compressors Impact Ice Production

The performance of an ice machine compressor directly influences how much ice you can produce within a given timeframe. A well-functioning compressor ensures optimal cooling cycles; if it's not operating correctly or has started showing signs like icing up—which leads many to wonder if it’s normal for a compressor to ice up—it could severely impact production rates.

When you ask yourself how to tell if an ice machine compressor is bad, look for symptoms such as unusual noises or insufficient cooling performance—these often indicate underlying issues that need immediate attention. Keeping tabs on these signs will help maintain consistent output levels while preventing costly repairs down the line.

In summary, understanding how compressors impact overall production helps in making informed decisions regarding maintenance schedules or potential replacements like RIGID's innovative mini compressors designed for efficiency without compromising quality—ideal for businesses looking to optimize their operations without breaking the bank.

Troubleshooting Ice Machine Compressors

When your ice machine compressor starts to misbehave, it can be frustrating and inconvenient. Understanding the reasons behind a malfunctioning compressor is essential for effective troubleshooting. In this section, we will explore common issues and symptoms that indicate your ice machine compressor may need attention.

Why is the Compressor Not Working on My Ice Machine?

If you find yourself asking, Why is the compressor not working on my ice machine? you're not alone. Various factors can cause an ice machine compressor to fail, including electrical issues, refrigerant leaks, or mechanical failures within the unit itself. Additionally, environmental conditions such as high ambient temperatures or inadequate airflow around the unit can also impact its performance.

Regular maintenance plays a crucial role in preventing these problems from arising in the first place. If your ice machine compressor isn't functioning properly, it’s important to inspect power supply connections and check for any visible signs of damage or wear and tear. Identifying these issues early can save you time and money on costly repairs down the line.

Common Symptoms of Compressor Failure

Recognizing common symptoms of compressor failure is key to addressing issues before they escalate into more significant problems. One of the first signs you might notice is unusual noises coming from the ice machine—such as rattling or humming sounds—that indicate something's amiss with the compressor operation. Additionally, if your ice production has significantly decreased or stopped altogether, this could signal that your ice machine compressor needs immediate attention.

Another symptom to watch for is excessive heat around the unit; if it feels unusually hot to touch or shows signs of icing up—yes, it's normal for a compressor to ice up under certain conditions—it may indicate underlying problems with refrigerant levels or airflow blockage. Keeping an eye on these warning signs allows you to take proactive steps toward maintaining your equipment efficiently.

How to Tell if an Ice Machine Compressor is Bad?

So how do you know how to tell if an ice machine compressor is bad? Start by performing some basic checks: listen for any strange sounds when it operates and monitor its temperature during use—too hot could mean trouble! Additionally, assess whether your unit cycles on and off frequently; this short cycling can be a clear indication that something isn’t functioning as it should.

Next up: inspect for visible damage like leaks around fittings or hoses connected to your ice machine compressor; these are often telltale signs that repairs may be necessary soon! Lastly, consider consulting with professionals who specialize in diagnosing issues related specifically to compressors—they'll have tools at their disposal that can quickly determine whether repair or replacement options are needed.

In conclusion, staying vigilant about potential issues with your ice machine compressor will help ensure smooth operation and prolong its lifespan while minimizing costs associated with repairs and replacements down the road!

Maintenance Tips for Your Ice Machine Compressor

Maintaining your ice machine compressor is essential for ensuring its longevity and optimal performance. Regular upkeep can prevent costly repairs and keep your ice production running smoothly. In this section, we’ll explore some vital maintenance tips to keep your ice machine compressor in top shape.

Routine Maintenance Practices

Routine maintenance practices are crucial for the health of your ice machine compressor. Regularly checking the refrigerant levels can help you identify any leaks or issues early on, avoiding a potential breakdown. Additionally, inspecting electrical connections and ensuring they are secure can prevent unexpected failures that might lead you to ask, “Why is the compressor not working on my ice machine?”

Another important aspect is monitoring the temperature settings and ensuring they align with manufacturer specifications. Keeping a log of maintenance activities can also help you track any recurring issues or patterns related to your compressor's performance. By staying proactive with these practices, you can significantly extend the life of your ice machine compressor.

Importance of Regular Cleanings

Cleaning your ice machine compressor regularly is vital for maintaining efficiency and preventing malfunctions. Dust and debris accumulation can obstruct airflow, causing the system to work harder than necessary, which may result in overheating or even failure over time. A clean environment helps ensure that components function optimally, so it's essential not to overlook this aspect of maintenance.

Moreover, regular cleanings help avoid unwanted contaminants that could compromise the quality of the ice produced by your machine. When cleaning, pay special attention to coils and filters; these areas often collect dirt that can hinder performance significantly if left unattended. After all, nobody wants to discover their ice production has dropped because their equipment was too dirty!

Signs Your Compressor Needs Attention

Recognizing signs that indicate your compressor may need attention is crucial in preventing more severe issues down the line. If you notice unusual noises coming from your ice machine compressor or observe inconsistent ice production, it might be time to investigate further—these could be signs of a failing unit asking you how to tell if an ice machine compressor is bad.

Another red flag includes excessive icing around the unit; while some frost formation is normal during operation, excessive buildup may indicate an underlying problem (Is it normal for a compressor to ice up?). If you're experiencing frequent cycling on and off without producing adequate amounts of ice, it's wise to consult a professional before things escalate into costly repairs or an eventual need for an ice machine compressor replacement.

Understanding Compressor Pricing

Ice Machine Compressor Price Factors

Several factors influence the price of an ice machine compressor, starting with its type and capacity. For instance, a high-efficiency compressor may come at a premium but can save you money in energy costs over time. Additionally, brand reputation plays a significant role; companies like RIGID are known for their innovative designs and superior quality, which can justify higher prices due to their reliability and performance in micro cooling systems.

Another important aspect is the technology embedded within the compressor itself. Newer models may feature advanced technologies that improve efficiency or reduce noise levels, making them more desirable despite potentially higher upfront costs. Lastly, geographical location can affect pricing; local market conditions and shipping fees may add to the overall expense when purchasing your ice machine compressor.

Budgeting for Ice Machine Maintenance

Budgeting for ice machine maintenance is essential to ensure your equipment operates smoothly over time. Regular maintenance not only prolongs the life of your ice machine compressor but also helps prevent costly repairs down the line—like needing to ask yourself Why is the compressor not working on my ice machine? unexpectedly! Setting aside a portion of your budget specifically for maintenance will allow you to address issues promptly before they escalate into more significant problems.

When planning your budget, consider both routine maintenance costs as well as unexpected repairs that might arise from wear and tear or environmental factors affecting your equipment's performance. It’s also wise to factor in potential costs associated with replacing parts like compressors if they fail—knowing how to tell if an ice machine compressor is bad could save you from unnecessary expenses by catching issues early on.

Analyzing Cost vs. Performance

Analyzing cost versus performance helps ensure that you're making smart investments when it comes to your ice machine compressor needs. While cheaper options might seem appealing initially, they often come with trade-offs such as lower durability or higher energy consumption—leading you back into that cycle of asking “Is it normal for a compressor to ice up?” due to inefficiencies!

On the other hand, investing in high-quality brands like RIGID means you're likely opting for superior performance backed by cutting-edge technology designed specifically for micro refrigeration applications. This balance between upfront investment and long-term savings should guide your decision-making process when selecting an ideal option that meets both budgetary constraints and operational requirements.

Replacement and Repair Options

Ice Machine Compressor Replacement Process

Replacing an ice machine compressor can seem daunting, but breaking it down into manageable steps makes it easier. First, ensure that you have diagnosed the problem accurately—asking yourself questions like “How to tell if an ice machine compressor is bad?” will guide your decision-making. Once you've confirmed that a replacement is necessary, disconnect power from the unit and remove any panels covering the compressor for access.

Next, you'll need to carefully detach the old compressor from its mounting brackets and disconnect all refrigerant lines. It’s important to handle these lines with care; improper handling could lead to leaks or further damage. After removing the old unit, install the new ice machine compressor by reversing these steps—attach it securely in place and reconnect all necessary lines before testing your system.

When to Repair vs. Replace

Deciding whether to repair or replace your ice machine compressor hinges on several factors including age, severity of damage, and cost-effectiveness. If your current unit is relatively new but showing symptoms of failure—like icing up—you might opt for a repair instead of a full replacement. However, if you find yourself frequently asking “Is it normal for a compressor to ice up?” or dealing with recurring issues after repairs, it may be time for a complete overhaul.

Consider also how much you're willing to invest in repairs versus purchasing a new unit outright; sometimes spending more now can save you headaches down the line if repairs become frequent and costly. Additionally, think about energy efficiency: newer models often consume less power compared to older units which can lead to savings on utility bills in the long run.

Benefits of Choosing RIGID Compressors

When selecting a new ice machine compressor for replacement, consider choosing RIGID compressors as they are known leaders in mini-compressor innovations in China. RIGID focuses on superior design and uncompromising quality while providing custom-made refrigeration solutions tailored specifically for clients’ needs—perfect if you're looking for efficiency without compromising performance! Their commitment not only enhances competitiveness but also ensures reliability in cooling systems across various applications.

Moreover, RIGID's rapid response times mean that customers can expect prompt service without sacrificing quality—a significant advantage when dealing with urgent repairs or replacements like an ice machine compressor failure! The growing list of satisfied clients speaks volumes about their dedication to customer satisfaction and innovation within micro cooling technology.

Conclusion

Keeping Your Ice Machine in Top Shape

To keep your ice machine in top shape, regular maintenance is key. This includes routine checks to ensure that the compressor is functioning properly and addressing any signs of wear or malfunction early on. Knowing how to tell if an ice machine compressor is bad can save you from costly repairs down the line, so always stay vigilant about its performance.

Additionally, understanding whether it’s normal for a compressor to ice up can help you identify potential problems before they escalate. If you notice excessive icing around the unit, it may signal that something isn't quite right with your compressor or cooling system. Regular cleanings and inspections will not only enhance efficiency but also extend the lifespan of your equipment.

Making Smart Decisions for Your Compressor

When it comes to making smart decisions for your ice machine compressor, weighing repair versus replacement options is essential. If you're asking yourself, Why is the compressor not working on my ice machine? consider both immediate fixes and long-term solutions based on age and condition. Sometimes investing in a new unit might be more cost-effective than pouring money into frequent repairs.

Budgeting for an Ice Machine Compressor price should also be part of your decision-making process; knowing upfront costs can help you avoid surprises later on. RIGID compressors offer innovative solutions at competitive prices that cater to various budgets while ensuring quality performance. Always conduct thorough research before committing to a purchase or service to ensure you're getting value for your investment.

The Future of Ice Machine Technology

The future of ice machine technology looks promising with advancements in efficiency and sustainability driving innovation forward. Companies like RIGID are leading this charge by developing mini compressors designed specifically for compact cooling needs without compromising on performance or reliability. As these technologies evolve, users will have access to even more efficient models that consume less energy while producing high-quality ice.

Emerging trends suggest that we will see smarter systems equipped with IoT capabilities allowing users to monitor their equipment remotely—making troubleshooting easier than ever before! As we embrace these changes, staying informed about developments in the industry will empower users to make better choices regarding their compressors and overall maintenance strategies.