Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of food preservation and temperature-sensitive storage, understanding cold storage refrigeration systems is paramount. These systems are designed to maintain specific temperatures to ensure that products remain fresh and safe for consumption. As industries increasingly rely on these technologies, knowing what cold storage is in a refrigeration system becomes essential for making informed decisions.

Understanding Cold Storage Needs

Cold storage needs vary significantly depending on the industry—be it pharmaceuticals, food service, or agriculture. Each sector has unique requirements for temperature control and product preservation, which directly influences the choice of equipment. By recognizing these needs, businesses can select the best cold storage refrigeration system that meets their operational demands while optimizing performance.

Key Components of Refrigeration Systems

A cold storage refrigeration system comprises several critical components that work in harmony to create an optimal environment for stored goods. Understanding these components—such as compressors, evaporators, and refrigerants—is vital when considering what refrigerant is used in cold storage applications. Additionally, familiarity with the three types of refrigeration systems—vapor-compression, absorption, and thermoelectric—can help businesses choose a solution tailored to their specific needs.

Importance of Choosing the Right Equipment

Selecting appropriate equipment is crucial for maximizing efficiency and minimizing costs in any cold room refrigeration system setup. The right choice not only ensures effective temperature control but also impacts energy consumption and overall operational expenses. As prices fluctuate across different models—think about cold storage refrigeration system price—it’s important to balance cost with quality to find the best cold storage refrigeration system suited for your business's requirements.

Overview of Cold Storage Refrigeration Systems

Cold storage refrigeration systems are essential for preserving perishable goods across various industries. These systems maintain low temperatures to slow down the degradation of products, ensuring quality and safety. Understanding what cold storage is in a refrigeration system can help businesses make informed decisions about equipment and processes.

Definition and Functionality

A cold storage refrigeration system is designed to create and maintain a controlled temperature environment for storing items that are sensitive to heat. Typically, these systems use refrigerants—substances that absorb heat from the environment—to lower temperatures effectively. The functionality of a cold room refrigeration system revolves around its ability to circulate cool air, thereby prolonging the shelf life of products.

Common Applications Across Industries

Cold storage refrigeration systems find applications in numerous sectors, including food and beverage, pharmaceuticals, and agriculture. In the food industry, they are crucial for storing meat, dairy products, fruits, and vegetables at optimal temperatures to prevent spoilage. Similarly, in pharmaceuticals, these systems ensure that vaccines and medications remain viable by maintaining strict temperature controls.

Benefits of Efficient Cold Storage

The benefits of efficient cold storage cannot be overstated; they include reduced spoilage rates and extended product shelf life. By utilizing the best cold storage refrigeration system available on the market today, businesses can significantly cut costs associated with waste due to expired goods. Additionally, an energy-efficient cold storage refrigeration system contributes positively to sustainability efforts by lowering overall energy consumption.

Essential Equipment in Cold Storage

Refrigeration Units Explained

So, what is cold storage in refrigeration systems? At its core, a refrigeration unit is designed to remove heat from a designated area and maintain a consistent low temperature. These units come in various sizes and capacities, tailored to meet specific requirements across different industries—from food service to pharmaceuticals—ensuring that sensitive products are stored safely.

The efficiency of a cold storage refrigeration system hinges on its design and functionality. Typically, these units operate using vapor-compression or absorption methods, which help regulate temperatures effectively. By understanding how these systems work, businesses can better assess their needs and make informed choices regarding their cold storage solutions.

Types of Compressors Used

Compressors play a vital role in any cold storage refrigeration system; they are essentially the heart of the operation! There are three main types of compressors commonly used: reciprocating, scroll, and screw compressors. Each type has its advantages—reciprocating compressors are known for their reliability, while scroll compressors offer quieter operation and higher efficiency.

What refrigerant is used in cold storage? The choice of refrigerants often depends on the compressor type as well as environmental regulations; common options include R-404A and R-134A due to their effectiveness at low temperatures. Understanding the differences between these compressor types helps businesses select the best fit for their specific cooling requirements.

Role of Evaporators in the System

Evaporators are another critical component in any cold room refrigeration system; they facilitate heat absorption from within the refrigerated space. As warm air passes over the evaporator coils filled with refrigerant, heat is removed, allowing cooler air to circulate back into the room—essentially creating that chilly environment we all love!

The efficiency of evaporators directly impacts energy consumption within a cold storage refrigeration system; thus, choosing high-quality models can lead to significant savings over time. Additionally, regular maintenance ensures that evaporators operate at peak performance levels while prolonging their lifespan—a win-win situation for any business relying on efficient cooling solutions.

Top-Mounted Monoblock Refrigeration Unit

Features of RIGID’s Monoblock System

RIGID’s monoblock system boasts several standout features that make it a leader in the cold storage refrigeration system market. With its all-in-one design, this unit integrates the compressor, condenser, and evaporator into one streamlined package. Not only does this simplify installation, but it also enhances efficiency by minimizing energy loss—a critical factor when considering cold storage refrigeration system price.

Additionally, RIGID’s monoblock units are designed to accommodate various refrigerants commonly used in cold storage applications. This flexibility allows for compliance with environmental regulations while ensuring optimal cooling performance. The durability and robust construction of these units ensure they can withstand the rigors of commercial use without compromising reliability.

Advantages for Commercial Use

The advantages of using a top-mounted monoblock refrigeration unit are particularly pronounced in commercial settings where efficiency is paramount. For businesses requiring reliable temperature control, understanding what refrigerant is used in cold storage can be crucial; RIGID's units utilize eco-friendly options that reduce environmental impact while maintaining excellent cooling capabilities.

Moreover, these systems are incredibly versatile and can be adapted to suit various types of cold storage needs—from perishable food items to pharmaceuticals—making them one of the best cold storage refrigeration systems available today. Their compact nature means they take up less space than traditional split systems while providing equal or greater cooling power.

Installation and Maintenance Benefits

Installation of RIGID’s top-mounted monoblock units is straightforward due to their self-contained design; there’s no need for extensive piping or complicated setups often associated with other types of refrigeration systems. This ease of installation translates into reduced labor costs and quicker operational readiness—a boon for businesses eager to get started with their new cold room refrigeration system.

Maintenance is equally hassle-free; these units typically require less frequent servicing compared to more complex systems due to fewer moving parts and integrated components. Regular monitoring ensures that your investment remains efficient over time—thus prolonging its lifespan while keeping energy costs low.

In conclusion, if you’re exploring options for your next commercial project or simply looking to upgrade your existing setup, consider the advantages offered by RIGID’s top-mounted monoblock refrigeration unit as part of your overall strategy for effective cold storage solutions.

Insulation and Building Materials

Importance of Proper Insulation

So, what is cold storage in refrigeration systems without adequate insulation? Without it, even the best cold storage refrigeration system can struggle to maintain optimal temperatures. Good insulation minimizes energy loss and reduces the workload on compressors, which can lead to longer equipment life and lower operational costs.

Common Materials Used

There are various materials used for insulating cold storage facilities, each with its unique benefits. Common options include polyurethane foam, polystyrene panels, and fiberglass batts; all of which have their pros and cons depending on specific needs. The selection often depends on factors like budget constraints—after all, cold storage refrigeration system price can vary significantly based on material choice—and desired thermal performance.

Impact on Energy Efficiency

The impact of proper insulation on energy efficiency cannot be overstated; it directly influences how well a cold room refrigeration system operates. High-quality insulation helps maintain stable temperatures while reducing energy consumption—essentially making your refrigeration system work smarter, not harder. In fact, investing in top-notch insulation can be one of the best ways to ensure your cold storage remains efficient while minimizing long-term costs.

Monitoring and Control Systems

In the realm of cold storage refrigeration systems, monitoring and control systems play a pivotal role in ensuring optimal performance. These systems help maintain the desired temperature and humidity levels essential for preserving perishable goods. With advancements in technology, modern monitoring solutions have become more sophisticated, offering real-time data and alerts to prevent costly spoilage.

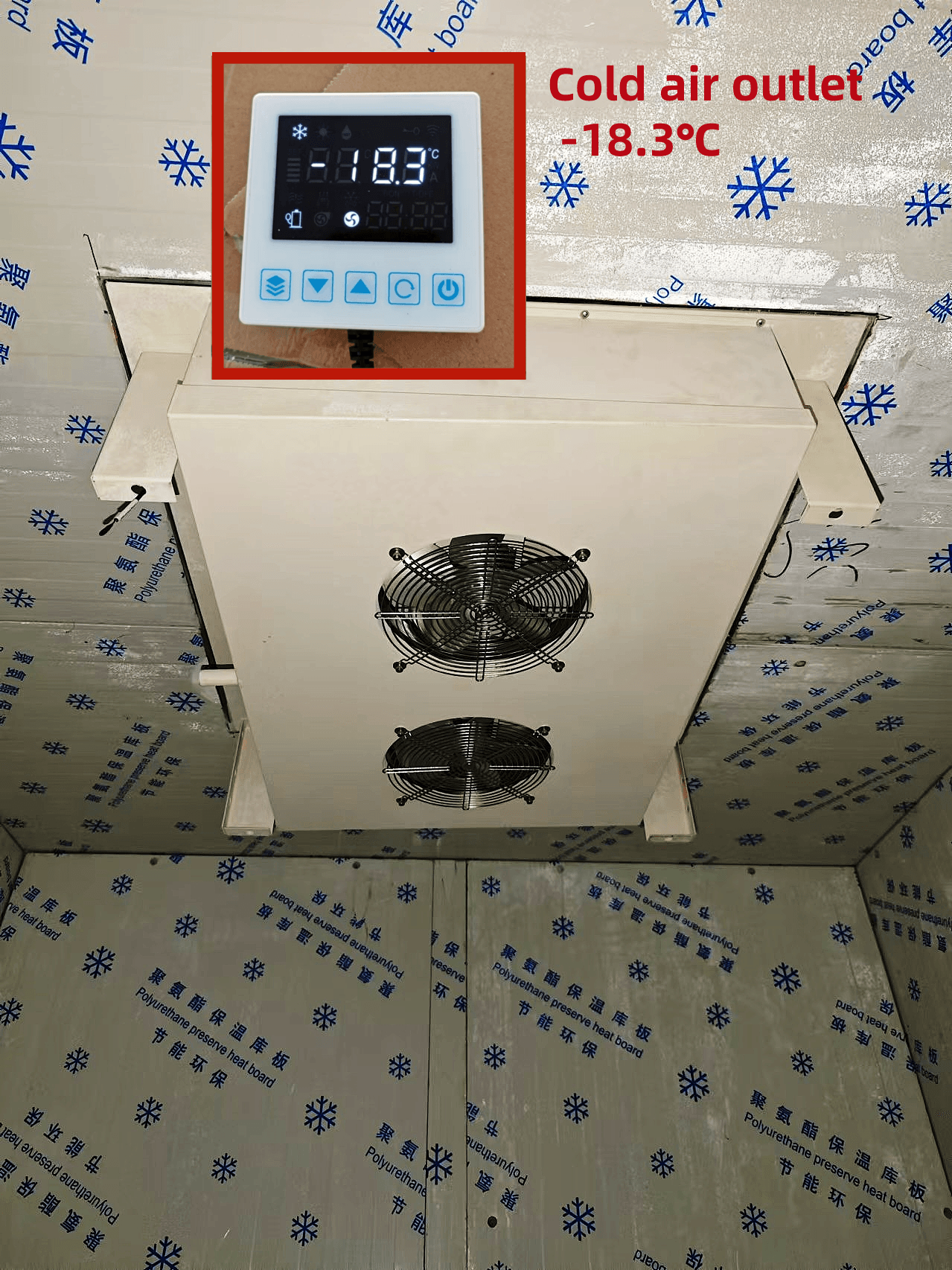

Types of Temperature Control Instruments

When it comes to temperature control instruments in cold storage refrigeration systems, there are several types to consider. Thermostats, digital controllers, and data loggers are among the most common tools used to regulate temperatures effectively. These instruments not only adjust cooling cycles but also provide critical insights into how a cold room refrigeration system works over time.

The choice of refrigerant is also vital; different refrigerants can affect the efficiency of these temperature control instruments. For instance, R-404A is widely used due to its effectiveness in low-temperature applications within cold storage refrigeration systems. Understanding what refrigerant is used in cold storage helps ensure compatibility with your chosen control instruments.

Importance of Accurate Monitoring

Accurate monitoring is crucial for any effective cold storage refrigeration system; it helps maintain product quality and compliance with safety standards. Fluctuations in temperature can lead to spoilage or degradation of stored items, making reliable monitoring essential for businesses relying on perishable goods. In fact, knowing how does a cold room refrigeration system work allows operators to respond quickly when deviations occur.

Moreover, continuous monitoring can significantly reduce energy costs by optimizing cooling cycles based on real-time data rather than fixed schedules. This proactive approach not only enhances efficiency but also contributes to sustainability goals within the industry—a win-win situation! The price of a cold storage refrigeration system may be higher initially but investing in accurate monitoring pays off through reduced waste and energy savings.

Innovations in Refrigeration Technology

The landscape of cold storage refrigeration systems is rapidly evolving thanks to innovations in technology that enhance both performance and user experience. Smart sensors equipped with IoT capabilities allow operators to monitor conditions remotely via smartphones or computers—no more running back and forth just to check temperatures! These advancements represent one of the best cold storage refrigeration system solutions available today.

Additionally, newer refrigerants with lower global warming potential are making waves as businesses seek greener options without sacrificing efficiency. There are two types of cold storage methods gaining traction: active (relying on mechanical systems) and passive (using insulation techniques) solutions that cater to diverse operational needs while minimizing environmental impact.

The future looks bright for those who embrace these innovations; they not only improve reliability but also pave the way for increased sustainability practices across industries reliant on effective refrigerated storage.

Conclusion

In the ever-evolving landscape of food preservation and product storage, selecting the right cold storage refrigeration system is crucial for ensuring quality and safety. Understanding what cold storage is in a refrigeration system can significantly impact your operational efficiency and cost-effectiveness. With various options available, it’s essential to assess your specific needs, from capacity to energy consumption, to find the best cold storage refrigeration system for your business.

Choosing the Right Cold Storage Equipment

When considering cold storage equipment, it's important to evaluate not only the type of refrigeration systems but also what refrigerant is used in cold storage applications. The three types of refrigeration systems—vapor-compression, absorption, and thermoelectric—each have their unique advantages and drawbacks depending on your operational requirements. Ultimately, investing time in research will guide you toward selecting a solution that meets both your budgetary constraints and performance expectations.

Future Trends in Cold Storage Refrigeration

The future of cold storage refrigeration systems looks promising with advancements in technology leading the way. Innovations such as smart monitoring systems are enhancing how we maintain temperature control while reducing energy consumption significantly. Furthermore, as sustainability becomes increasingly important across industries, we can expect more eco-friendly refrigerants to emerge alongside energy-efficient designs that cater to both environmental concerns and economic viability.

Enhancing Efficiency and Sustainability

Enhancing efficiency within a cold room refrigeration system involves a multifaceted approach that includes proper insulation materials and regular maintenance checks. By understanding how does a cold room refrigeration system work alongside integrating efficient practices like using high-quality insulation materials, businesses can reduce their overall operating costs while improving product longevity. As energy prices continue to rise, investing in efficient technologies will not only benefit your bottom line but also contribute positively towards sustainability goals.