Introduction

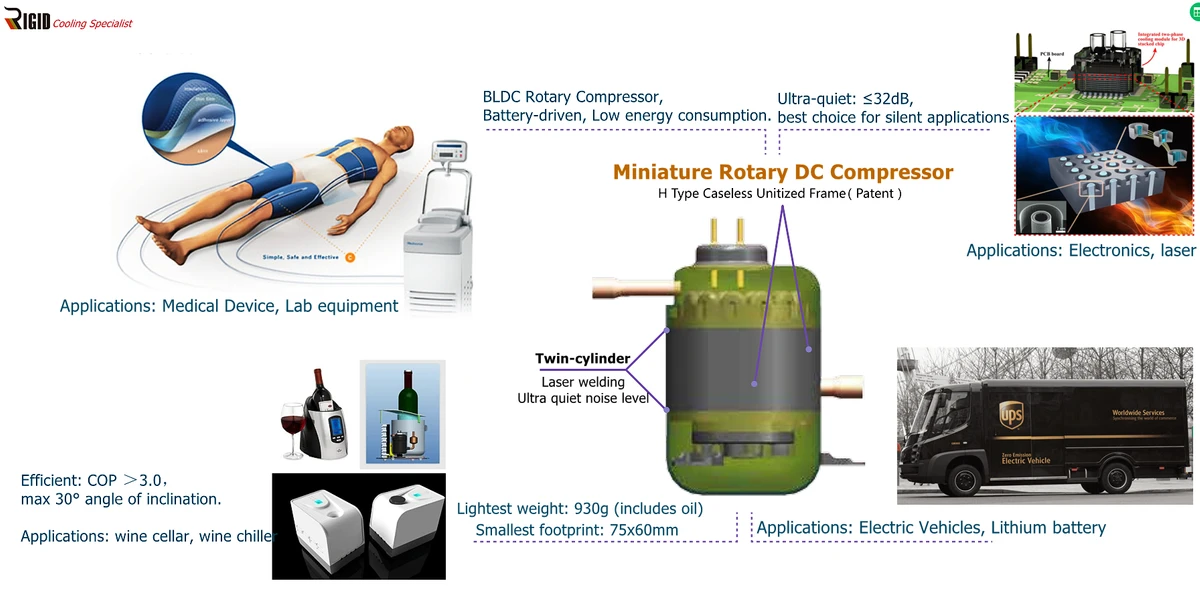

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

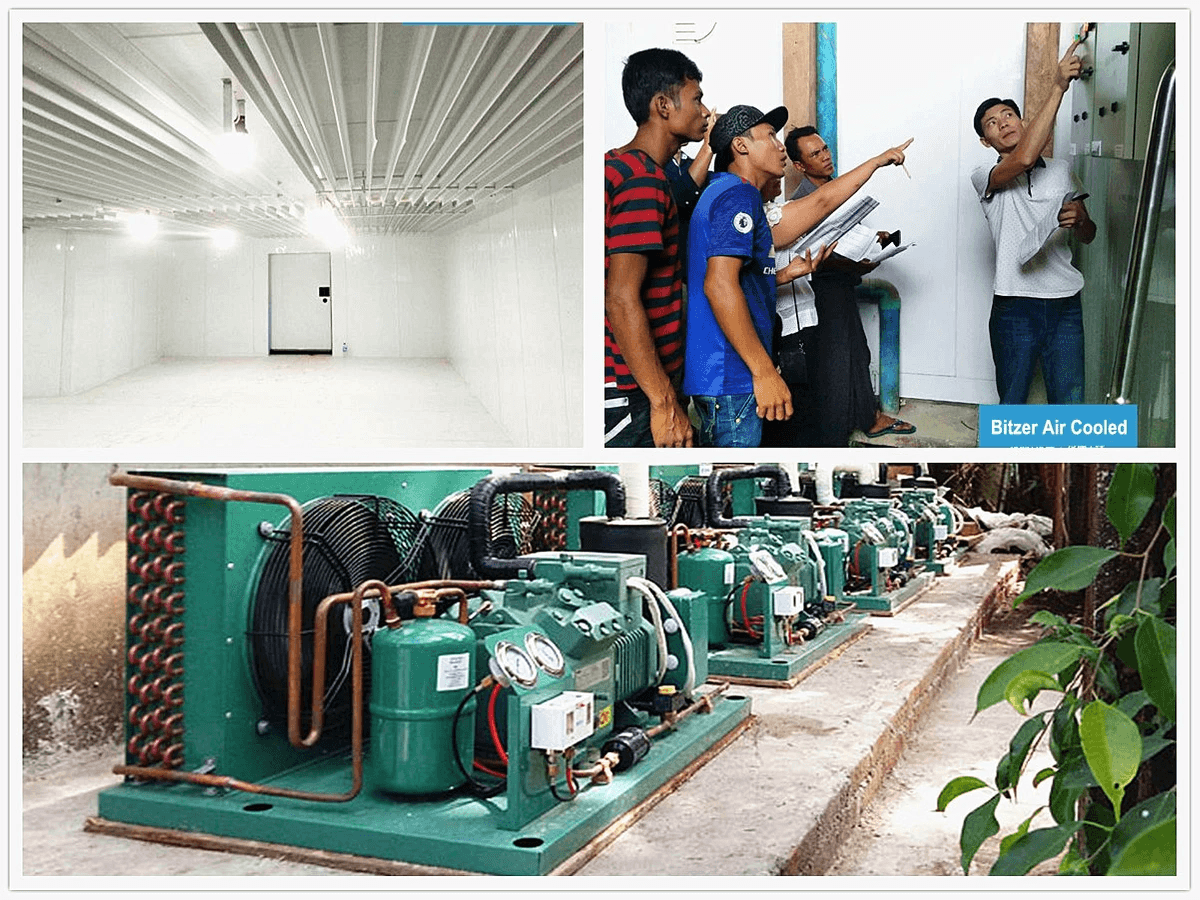

In today's fast-paced world, the importance of cold room refrigeration systems cannot be overstated. These systems are essential for preserving perishable goods, maintaining quality and safety in food storage, pharmaceuticals, and other temperature-sensitive products. The best cold room refrigeration system ensures that businesses can operate efficiently while minimizing waste and maximizing profit.

Importance of Cold Room Refrigeration Systems

Cold room refrigeration systems play a vital role in various industries by providing controlled environments for the storage of diverse products. From restaurants to warehouses, these systems help maintain optimal temperatures that prevent spoilage and extend shelf life. Understanding the significance of these units is crucial for any business looking to thrive in competitive markets.

Factors Affecting Refrigeration Efficiency

Several factors can influence the efficiency of cold room refrigeration systems, including insulation quality, ambient temperature, and equipment maintenance. A well-designed cold room will consider these elements to ensure maximum performance while keeping energy consumption low. Additionally, understanding how each factor impacts overall efficiency can help businesses select the best cold room refrigeration system tailored to their needs.

Choosing the Right Equipment

Selecting the right equipment is critical when investing in a cold room refrigeration system; it can make or break your operational success. Businesses should create a detailed cold room equipment list that encompasses all necessary components while considering their specific requirements and budget constraints like cold room design and installation costs. Moreover, evaluating options such as outdoor units can provide additional flexibility while ensuring you get value for your investment with a reasonable cold room refrigeration system price.

Understanding Cold Room Refrigeration Systems

Cold room refrigeration systems are essential for preserving perishable goods across various industries, including food and pharmaceuticals. These systems maintain optimal temperatures to prevent spoilage and ensure product integrity. By understanding their design and functionality, businesses can make informed decisions when investing in the best cold room refrigeration system for their needs.

Definition and Applications

A cold room refrigeration system is a specialized cooling solution designed to maintain a controlled environment for storing temperature-sensitive items. These systems are widely used in supermarkets, warehouses, and hospitals to store products like fresh produce, dairy, meats, and vaccines. With a tailored cold room design, businesses can enhance their operational efficiency while ensuring compliance with health regulations.

Key Components Explained

The key components of a cold room refrigeration system include the compressor, evaporator, condenser, and insulation panels. The compressor circulates refrigerant throughout the system while the evaporator absorbs heat from inside the cold room to lower the temperature effectively. Insulation panels play a crucial role in minimizing thermal exchange with the external environment, making them vital for energy efficiency in any cold room equipment list.

Benefits for Businesses

Investing in a reliable cold room refrigeration system provides numerous advantages for businesses looking to optimize their storage capabilities. Not only do these systems help extend shelf life and reduce waste, but they also enhance product quality by maintaining consistent temperatures within common temperature ranges. Additionally, having an efficient cold room setup can lead to significant long-term cost savings by lowering energy consumption—especially when choosing from an updated cold room equipment price list that highlights energy-efficient models.

The Role of Temperature Control

Temperature control is the backbone of any effective cold room refrigeration system. Maintaining the right temperature ensures that perishable goods remain fresh, safe, and suitable for consumption or storage. Failing to regulate temperature properly can lead to spoilage, waste, and financial losses for businesses relying on cold storage.

Importance of Temperature Regulation

Temperature regulation is crucial in a cold room refrigeration system because it directly impacts the quality and longevity of stored products. For instance, if the temperature fluctuates beyond acceptable limits, it can compromise food safety and lead to health risks. Furthermore, consistent temperature control helps maintain product integrity, ensuring that businesses deliver high-quality goods to their customers.

Common Temperature Ranges

The common temperature ranges for a cold room refrigeration system vary depending on what is being stored. Typically, fresh produce requires temperatures between 32°F and 41°F (0°C to 5°C), while frozen items need to be kept at or below 0°F (-18°C). Understanding these ranges is essential when designing a cold room; it allows businesses to optimize their cold room equipment list for specific applications.

Impact on Stored Goods

The impact of improper temperature management on stored goods cannot be overstated; it can lead to significant losses in both quality and quantity. For example, dairy products may spoil quickly if not kept within their ideal range, while frozen meats can suffer from freezer burn if temperatures fluctuate too much. Thus, investing in the best cold room refrigeration system with precise controls not only protects your inventory but also enhances your bottom line by reducing waste.

Top-Mounted Monoblock Refrigeration Unit

Features of the RIGID Unit

The RIGID unit boasts an array of features that make it one of the best cold room refrigeration systems on the market. Its compact design allows for easy installation and integration into existing cold room designs without taking up valuable floor space. Additionally, it comes equipped with advanced temperature control technology and robust insulation, ensuring that your stored goods remain at consistent temperatures regardless of external conditions.

One standout feature is its user-friendly digital display that allows operators to monitor and adjust settings effortlessly. The RIGID unit also employs a high-efficiency compressor that not only enhances cooling performance but also contributes to lower energy consumption—an essential factor when evaluating cold room equipment price lists. All these attributes collectively enhance its appeal as a top choice in the realm of cold room refrigeration systems.

Benefits of Plug-and-Play Installation

One major advantage of the top-mounted monoblock refrigeration unit is its plug-and-play installation capability. This feature simplifies setup and significantly reduces downtime during installation, allowing businesses to start using their cold rooms almost immediately after purchase. Such ease-of-installation is especially beneficial for those looking to upgrade their current setups or expand their operations without extensive delays.

Furthermore, plug-and-play systems require minimal technical expertise for installation, making them accessible even for small businesses with limited resources or knowledge in refrigeration technology. This aspect can also lead to reduced labor costs compared to traditional systems requiring complex installations and adjustments—something worth considering when reviewing any cold room equipment price list. Overall, this convenience makes it an attractive option for anyone seeking efficient solutions in their cold storage needs.

Eco-Friendly Refrigerant Importance

In today's environmentally conscious world, choosing a refrigeration system that utilizes eco-friendly refrigerants has become increasingly important. The RIGID unit employs refrigerants with low global warming potential (GWP), which align with modern regulations aimed at reducing environmental impact from industrial processes like those involved in running a cold room refrigeration system. Opting for such eco-friendly solutions not only helps businesses comply with legal standards but also appeals to customers who prioritize sustainability.

Moreover, using eco-friendly refrigerants can lead to long-term cost savings as they often result in improved energy efficiency and reduced operational costs over time—benefits that are crucial when assessing overall cold room refrigeration system price points against performance metrics. As businesses strive toward greener practices, investing in equipment designed with environmental considerations will likely become a standard expectation rather than an exception.

Energy Efficiency Considerations

When it comes to cold room refrigeration systems, energy efficiency is not just a buzzword; it's a necessity. With rising energy costs and increasing environmental concerns, choosing the best cold room refrigeration system can significantly impact both your budget and your carbon footprint. Understanding how to evaluate energy consumption and select efficient models is essential for any business looking to optimize their cold storage solutions.

Evaluating Energy Consumption

To get the most out of your cold room refrigeration system, evaluating energy consumption is crucial. Start by reviewing the unit's specifications, paying attention to its power usage in kilowatts (kW) and its overall cooling capacity. This information will help you gauge how much energy your cold room equipment will consume over time, allowing you to make informed decisions about which models are the most efficient.

Another key factor in evaluating energy consumption is understanding the operating conditions of your cold room design. Factors such as ambient temperature, humidity levels, and insulation quality can all affect how hard your refrigeration unit has to work. By monitoring these variables, businesses can identify potential inefficiencies in their systems and make necessary adjustments.

Lastly, consider utilizing smart technology that tracks real-time energy usage for your cold room refrigeration system. These tools not only provide insights into performance but also highlight areas where improvements can be made—ultimately leading to reduced operational costs.

Choosing Energy-Efficient Models

When selecting a new cold room refrigeration system, prioritizing energy-efficient models can lead to significant savings over time. Look for units that have earned certifications like ENERGY STAR or other recognized efficiency labels; these indicators often signify that the model meets strict standards for energy performance. Investing in high-quality equipment may have a higher upfront cost but pays off through lower utility bills.

Additionally, consider features such as variable speed compressors and advanced controls that allow for better temperature regulation while consuming less power. These technologies ensure that the system operates only when needed—saving both electricity and wear on components over time.

A well-curated cold room equipment list should include options known for their reliability and efficiency ratings so you can make an informed choice with confidence.

Long-term Cost Savings

Investing in an efficient cold room refrigeration system goes beyond immediate financial considerations; it’s about long-term cost savings too! While initial prices may vary across different models—reflected in various price lists—it’s important to think about total cost of ownership over several years rather than simply focusing on upfront expenses.

Energy-efficient systems typically result in lower monthly utility bills due to reduced power consumption—a benefit that compounds over time as prices rise or fluctuate unpredictably in today’s market landscape. Moreover, these units often require less maintenance due to their advanced technology and superior construction materials—saving you money on repairs or replacements down the line.

In conclusion, making wise choices regarding energy consumption evaluation and selecting top-notch models will lead businesses toward sustainable practices while keeping budgets intact—a win-win situation!

Maintenance Best Practices

Maintaining a cold room refrigeration system is crucial for ensuring its efficiency and longevity. Regular practices can prevent costly breakdowns and extend the lifespan of your equipment, making it vital for businesses relying on cold storage. This section covers essential maintenance strategies, including regular inspections, common issues to watch for, and tips to maximize your cold room's effectiveness.

Regular Inspection and Cleaning

Regular inspection and cleaning of your cold room refrigeration system are essential to keep it running smoothly. Schedule routine checks to ensure all components are functioning correctly; this includes inspecting the evaporator coils, condenser coils, and fans for dirt or obstructions that could hinder performance. Cleaning these parts not only enhances efficiency but also helps maintain optimal temperature control within the cold room.

In addition to mechanical parts, don't overlook the importance of checking seals on doors and gaskets in your cold room design. Ensuring these seals are intact prevents warm air from entering the space, which could lead to increased energy consumption and spoilage of stored goods. By keeping a clean environment in both your indoor space and outdoor unit, you can significantly improve the overall performance of your best cold room refrigeration system.

Common Issues to Watch For

Being proactive about maintenance means being aware of common issues that may arise with a cold room refrigeration system. One prevalent problem is inadequate cooling due to refrigerant leaks; this can severely impact temperature regulation within the unit. Regularly monitoring refrigerant levels will help you catch leaks early before they escalate into larger problems that could require extensive repairs or replacement.

Another issue often encountered is frost buildup on evaporator coils, which can restrict airflow and lead to inefficient cooling cycles. Keeping an eye out for excessive frost accumulation will allow you to take corrective measures promptly—such as defrosting—to maintain optimal conditions inside your refrigerated space. Additionally, listen for unusual noises from compressors or fans; strange sounds often indicate mechanical problems that need immediate attention.

Tips for Extending Lifespan

To extend the lifespan of your cold room refrigeration equipment effectively, consider implementing a few simple yet impactful practices into your maintenance routine. First off, ensure that all components receive regular lubrication as per manufacturer guidelines; this helps reduce wear and tear on moving parts within the system over time.

Secondly, invest in high-quality filters designed specifically for your type of cold room equipment; replacing them regularly will improve air circulation while reducing strain on the compressor unit itself—ultimately prolonging its life span! Lastly, keep detailed records of all maintenance activities performed along with any repairs made—this not only aids in troubleshooting issues but also provides valuable insights when evaluating potential upgrades or replacements down the line.

Conclusion

In wrapping up our exploration of cold room refrigeration systems, it’s clear that these systems are vital for businesses that require precise temperature control. From understanding the components to recognizing the importance of maintenance, every aspect plays a critical role in ensuring efficiency and longevity. Whether you're considering the best cold room refrigeration system or evaluating a cold room equipment price list, informed decisions can lead to substantial long-term benefits.

Key Takeaways on Refrigeration Systems

Cold room refrigeration systems are essential for preserving perishable goods across various industries, from food storage to pharmaceuticals. When selecting the best cold room refrigeration system, it’s crucial to consider both energy efficiency and application-specific needs. Additionally, being aware of your cold room design can significantly enhance operational efficiency and reduce costs associated with energy consumption.

Importance of Proper Maintenance

Proper maintenance is non-negotiable when it comes to maximizing the lifespan and performance of your cold room refrigeration system. Regular inspections and cleaning help identify common issues before they escalate into costly repairs or downtime. By adhering to a well-planned maintenance schedule, you not only extend the life of your equipment but also ensure optimal performance at all times.

Future Trends in Cold Room Technology

As technology evolves, so do cold room refrigeration systems—leading us into an era marked by innovation and sustainability. Emerging trends include advanced temperature control technologies and eco-friendly refrigerants that align with global environmental goals. Keeping an eye on these advancements will be essential for businesses looking to stay competitive while managing their cold room equipment price list effectively.