Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the bustling world of supermarkets, maintaining optimal temperatures is crucial for preserving food quality and safety. Supermarket refrigeration needs are unique, requiring specialized equipment that can handle large volumes of perishables while ensuring energy efficiency. Understanding these requirements is the first step toward selecting the right supermarket refrigeration compressor for your business.

Understanding Supermarket Refrigeration Needs

Supermarkets have diverse refrigeration needs due to their vast array of products, from fresh produce to frozen items. The efficient operation of commercial freezers and refrigerator commercial units hinges on reliable cooling compressor refrigeration systems that can adapt to varying demands throughout the day. Assessing these needs allows supermarket owners to choose equipment that not only meets current demands but also accommodates future growth.

The Importance of Quality Compressors

Quality compressors play a pivotal role in maintaining consistent temperatures in fridge commercial setups, ensuring that food remains fresh and safe for consumption. A high-quality supermarket refrigeration compressor minimizes downtime and reduces maintenance costs, which can significantly impact a supermarket's bottom line. Investing in superior compressors also enhances energy efficiency, leading to lower operational costs over time.

Types of Compressors in Supermarkets

When it comes to supermarket refrigeration compressors, several types cater to specific needs and applications within the store environment. Common options include reciprocating compressors, scroll compressors, and screw compressors, each offering unique advantages depending on factors like size and capacity requirements. By understanding these types and their functionalities, supermarket operators can make informed decisions that support both operational efficiency and customer satisfaction.

Overview of Supermarket Refrigeration Compressors

In any bustling supermarket, refrigeration compressors serve as the backbone of food preservation. A supermarket refrigeration compressor manages the cooling processes essential for keeping perishables fresh and safe for consumers. Understanding the different types and functions of these compressors is crucial for optimizing operations and ensuring product quality.

What is a Supermarket Refrigeration Compressor?

A supermarket refrigeration compressor is a device that compresses refrigerant gas, allowing it to circulate through the cooling system in commercial freezers and refrigerators. This process is vital for maintaining low temperatures, which helps prevent spoilage and waste of perishable goods. Without a reliable refrigeration compressor, even the best fridge commercial units would struggle to keep their contents at safe temperatures.

Key Types of Refrigeration Compressors

The most common types include reciprocating, scroll, and rotary compressors; each has its own strengths suited for specific applications within a supermarket environment. Choosing the right type can significantly impact energy efficiency and overall performance in both commercial freezer units and refrigerator commercial models.

How Compressors Affect Supermarket Operations

Compressors play an integral role in supermarket operations by directly influencing temperature control, energy consumption, and product quality. An efficient cooling compressor refrigeration system can lead to lower operational costs while ensuring that food items remain fresh longer—an essential factor in customer satisfaction. Moreover, understanding refrigeration compressor capacity helps supermarkets plan their layouts effectively, maximizing space while minimizing waste due to spoilage.

The Role of Commercial Freezers and Refrigerators

In the bustling environment of a supermarket, commercial freezers and refrigerators play an essential role in maintaining product quality and safety. These units are designed to keep perishable items at optimal temperatures, ensuring everything from fresh produce to frozen foods remains in top condition. Understanding their functionality is crucial for any supermarket looking to optimize operations and enhance customer satisfaction.

Essential Functionality of Commercial Freezers

Commercial freezers are indispensable in supermarkets, serving as the backbone for frozen goods storage. They maintain a consistent low temperature that prevents spoilage, allowing retailers to offer a variety of products year-round. Moreover, the efficiency of a supermarket refrigeration compressor directly impacts the performance of these freezers; a high-quality compressor ensures rapid cooling and energy savings.

Additionally, commercial freezers often come equipped with advanced features like digital temperature controls and alarms that alert staff to any fluctuations. This functionality not only helps in maintaining food safety standards but also reduces waste by minimizing the risk of spoilage. When selecting a commercial freezer, it's vital to consider how its design complements your overall refrigeration strategy.

Choosing the Right Refrigerator Commercial Models

Selecting the right refrigerator commercial model is akin to choosing the right partner—compatibility is key! Supermarkets must assess their specific needs based on layout and product offerings before diving into options. Factors such as size, shelving configuration, and energy efficiency should guide decisions since they all influence how well a fridge commercial unit operates within your space.

Another critical consideration is the refrigeration compressor capacity required for various models; some units may need more robust compressors than others due to higher product turnover or larger storage volumes. An efficient cooling compressor refrigeration system not only saves on energy costs but also enhances overall performance consistency across your supermarket's refrigerated sections. Ultimately, investing time in choosing the right model can lead to significant long-term benefits.

Differences in Compressor Requirements for Various Units

When it comes to supermarket refrigeration compressors, one size does not fit all! Different types of refrigerators require varying levels of compressor power based on their intended use—think about how deli counters might differ from ice cream freezers or beverage coolers. For instance, display cases might necessitate higher-capacity compressors due to constant door openings compared with standard storage units that have less frequent access.

Understanding these differences helps supermarkets tailor their systems effectively while optimizing energy consumption—a win-win situation! Furthermore, knowing which refrigerator parts are crucial for specific applications can streamline maintenance efforts down the line; regular upkeep ensures longevity and reliability across all cooling units within your store. In essence, recognizing these nuances allows operators to maximize efficiency while minimizing operational headaches.

Factors Influencing Refrigeration Compressor Capacity

When it comes to the performance of a supermarket refrigeration compressor, size plays a pivotal role. A larger compressor generally has the capacity to handle greater cooling demands, making it essential for commercial freezers and refrigerators that store significant amounts of perishable goods. However, simply opting for a bigger unit isn't always the best solution; it's crucial to match size with specific operational needs.

How Size Impacts Performance

The size of a refrigeration compressor directly influences its efficiency and effectiveness in maintaining optimal temperatures within fridge commercial units. A compressor that is too small may struggle to keep up with demand during peak hours, leading to higher energy costs and potential spoilage of products. Conversely, an oversized unit can lead to short cycling—where the compressor frequently turns on and off—which can reduce its lifespan and increase wear on refrigerator parts.

In addition, the physical dimensions of your supermarket layout should inform your choice of compressor size. For instance, if your store has limited space for equipment installation, you might need a compact cooling compressor refrigeration system that still meets your needs without overwhelming the area. Thus, understanding how size impacts performance is essential for effective supermarket operations.

Assessing Cooling Needs for Supermarket Layouts

To accurately assess cooling needs for different supermarket layouts, one must evaluate several factors including product types, storage duration, and customer traffic patterns. Different areas within a supermarket may require varying levels of cooling; fresh produce sections usually demand more intensive refrigeration compared to dry goods aisles. This nuanced approach ensures that each section is equipped with the right type of refrigerator commercial model tailored to its specific requirements.

Additionally, understanding peak shopping times helps in determining how much refrigeration compressor capacity will be necessary at any given moment. If your store experiences high foot traffic during certain hours or days, ensuring that your commercial freezers are adequately sized will prevent overheating and maintain food safety standards effectively. Ultimately, assessing these factors leads to better inventory management and customer satisfaction.

The Balance Between Efficiency and Capacity

Finding the right balance between efficiency and capacity is like walking a tightrope; too much emphasis on one can jeopardize the other in supermarket refrigeration systems. While larger compressors may offer higher capacities for extensive cooling needs, they often consume more energy—leading to inflated operational costs that can eat into profits over time. On the flip side, prioritizing energy efficiency might mean sacrificing some capacity during peak demand periods when every degree matters.

Choosing an optimal configuration involves strategic planning; integrating variable speed compressors or advanced control systems can help achieve this delicate balance by adjusting output based on real-time conditions within fridge commercial setups. This flexibility allows supermarkets not only to meet their immediate cooling demands but also enhance overall energy efficiency—a win-win scenario! By investing in technology that supports both aspects simultaneously, businesses can secure their competitive edge while keeping operational costs manageable.

Rigid Innovations in Cooling Technology

In the ever-evolving world of supermarket refrigeration, Rigid has emerged as a pioneer in innovative cooling technologies. These advancements are crucial for enhancing the efficiency and effectiveness of commercial freezers and refrigerator commercial units. By focusing on mini compressors and custom solutions, Rigid is setting new standards for performance and energy savings.

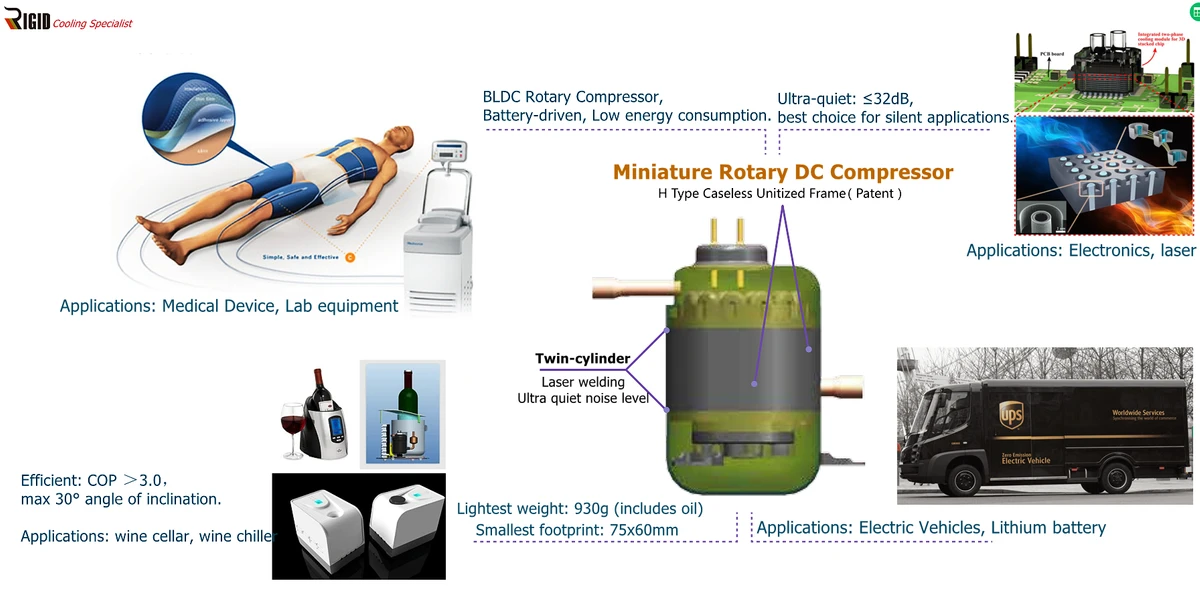

Mini Compressors Leading the Market

Mini compressors are revolutionizing the landscape of supermarket refrigeration compressors by offering compact yet powerful solutions. These small but mighty units are designed to fit into tight spaces while still delivering robust cooling capabilities, making them ideal for modern retail environments. With their ability to maintain optimal temperatures in fridge commercial setups, mini compressors have become a favorite among supermarket operators looking to maximize both space and efficiency.

The rise of mini compressors also signifies a shift towards more sustainable practices within the industry. By consuming less energy while maintaining high performance levels, these compact models help supermarkets reduce their carbon footprint without sacrificing quality or reliability. This trend is particularly beneficial as retailers strive to meet increasing consumer demand for eco-friendly operations.

Custom Solutions for Unique Refrigeration Needs

Not all supermarkets are created equal, which is why custom solutions play an essential role in meeting specific refrigeration needs. Rigid offers tailored configurations that address unique challenges faced by different businesses, whether it be accommodating unusual layouts or specialized product requirements. These customized refrigeration compressor capacity options ensure that every supermarket can find a solution that perfectly aligns with its operational demands.

By investing in bespoke refrigeration systems, supermarkets can optimize their inventory management and enhance overall customer satisfaction. For instance, certain products may require specific temperature zones that standard models cannot provide—this is where custom designs shine. Tailoring equipment not only improves performance but also helps businesses stand out in a competitive marketplace.

Rigid's Impact on Energy Efficiency

Energy efficiency has become a critical concern for supermarkets looking to cut costs and reduce environmental impact; this is where Rigid truly excels with its innovative technologies. The company’s focus on developing energy-efficient refrigerator parts ensures that all components work harmoniously together to minimize waste while maximizing cooling performance across commercial freezer units and refrigerator commercial setups alike.

Rigid’s commitment to energy efficiency goes beyond just hardware; it extends into smart technology integration as well. By incorporating advanced monitoring systems into their refrigeration compressor offerings, supermarkets can track energy usage patterns and make informed decisions about optimizing operations further—leading to significant cost savings over time. This proactive approach not only benefits the bottom line but also supports broader sustainability goals within the retail sector.

Common Refrigerator Parts and Maintenance Tips

Keeping your commercial refrigeration systems running smoothly is crucial for any supermarket operation. Understanding the essential parts of your refrigerator commercial units, performing regular maintenance, and knowing how to troubleshoot common issues can save you time, money, and a potential loss of inventory. Let’s dive into the nitty-gritty of refrigerator care.

Essential Parts of a Refrigerator Commercial

A commercial refrigerator consists of several key components that work together to keep your products at the ideal temperature. The refrigeration compressor is arguably the heart of this system, responsible for circulating refrigerant throughout the unit to maintain cooling efficiency. Other important refrigerator parts include evaporators, condensers, expansion valves, and fans; each plays a vital role in ensuring optimal performance for both your fridge commercial and commercial freezer.

Understanding these components helps you appreciate how they contribute to refrigeration compressor capacity. For instance, if one part malfunctions or becomes less efficient over time, it can lead to increased energy consumption or temperature fluctuations in your supermarket refrigeration compressor system. Regularly inspecting these parts can prevent costly repairs down the line.

Regular Maintenance for Optimal Performance

To ensure that your supermarket refrigeration compressor operates at peak efficiency, implementing a regular maintenance schedule is essential. This includes cleaning condenser coils to remove dust and debris that can hinder performance; dirty coils are often a leading cause of inefficient cooling in refrigerators and freezers alike. Additionally, checking door seals for wear and tear can prevent cold air from escaping—keeping those precious perishables at just the right temperature.

Another important aspect is monitoring refrigerant levels; low levels can indicate leaks or other issues that could compromise cooling compressor refrigeration effectiveness. By staying on top of these maintenance tasks, you’ll not only extend the life of your equipment but also enhance its energy efficiency—saving money on utility bills while keeping food fresh for customers.

Troubleshooting Common Issues

Even with regular upkeep, issues may still arise with your refrigerator commercial units or commercial freezers from time to time; knowing how to troubleshoot them can be invaluable. If you notice unusual noises coming from your supermarket refrigeration compressor or inconsistent temperatures inside the unit, it might be time to check if there’s an issue with airflow or if filters need cleaning or replacing.

Another common problem is frost buildup inside freezers—a sign that door seals may not be functioning properly or that airflow is restricted by ice accumulation. Addressing these issues promptly will help maintain optimal refrigeration compressor capacity and prevent more significant problems later on.

Lastly, keep an eye out for frequent cycling on and off; this could indicate an issue with thermostat settings or even a failing cooling compressor refrigeration system component that requires immediate attention before it leads to breakdowns during peak hours.

Conclusion

In the ever-evolving landscape of supermarket operations, understanding the nuances of refrigeration is paramount. The right supermarket refrigeration compressor can make or break a business, influencing everything from energy consumption to product freshness. As we look ahead, it’s clear that innovations in cooling technology will continue to shape how supermarkets operate, ensuring they meet both customer demands and sustainability goals.

Future Trends in Supermarket Refrigeration

The future of supermarket refrigeration is leaning heavily towards enhanced energy efficiency and smarter technology integration. With advancements in cooling compressor refrigeration systems, supermarkets are now able to monitor performance in real-time, allowing for proactive maintenance and reduced downtime. Additionally, the rise of eco-friendly refrigerants is paving the way for more sustainable practices within the industry, ensuring that commercial freezers and refrigerators align with global environmental standards.

Finding the Right Solutions for Your Business

Choosing the right refrigerator commercial models requires a thorough understanding of your specific needs and layout requirements. Different stores may demand varying refrigeration compressor capacity based on their size and product offerings; thus, a tailored approach is essential. By investing time in evaluating your options—whether it's selecting mini compressors or larger units—supermarkets can optimize their operations while maintaining product quality and customer satisfaction.

Leveraging Innovation for Competitive Advantage

Innovation isn’t just a buzzword; it’s a necessity for supermarkets looking to stand out in a crowded market. By leveraging cutting-edge technologies such as advanced fridge commercial designs or custom solutions tailored to unique needs, businesses can enhance their operational efficiency significantly. Furthermore, staying abreast of new developments in refrigerator parts and maintenance techniques ensures that you’re not only keeping up with competitors but also setting new standards within the industry.