1. BACKGROUND

RIGID HVAC Compact And Effective Thermal Modeling:

As lithium-ion batteries become more effective, high-performance charging stations become more necessary to power hybrid and electric vehicles. During charging, all components of these charging stations have to maintain an optimal temperature level – firstly, because rapid charging processes massively heat the entire system, and secondly, in order to reduce negative effects on the range of the electric car and the life of the batteries.

In addition, electric vehicles are becoming more popular because of their faster charging times. Yet, rapid charging processes develop a great deal of heat losses leading to massive waste heat flows. To ensure a continuously high charging cycle, an efficient thermal management is required.

There is no better solution here than efficient vapor compression thermal management based on liquid cooling. Plastic conduits and connectors with sensors and matching conduits ensure optimum safety with a tight cooling system.

2. Thermal Management To EV Charging Station

RIGID Cooling Provides Thermal Solution To Electric Vehicle During Charging:

RIGID vapor compressor cooling systems provide a method of thermally conditioning to energy storage of a vehicle while charging.

RIGID designed cooling systems are applied to many applications including: receiving, at a charging station, thermal information about the energy storage; supplying, by the charging station, electric energy to the energy storage in a charging session; and providing, by the charging station and based on the thermal information, thermal conditioning of the energy storage during at least part of the charging session.

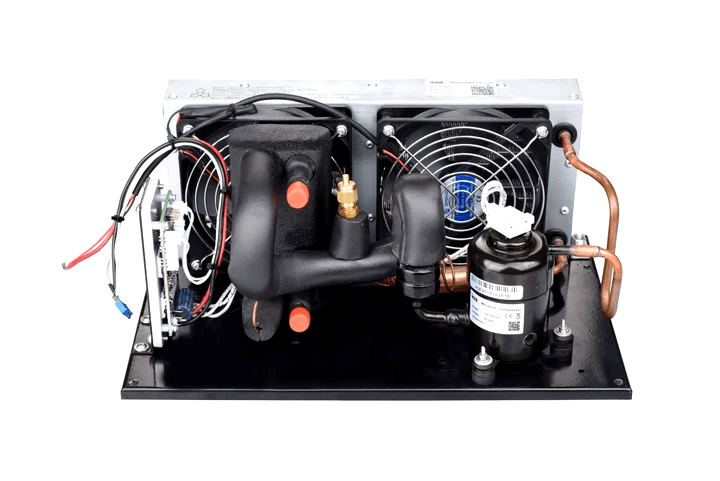

During fast charging processes, the entire charging station heats up strongly, so efficient heat management is crucial. A compact and portable liquid chiller made of miniature DC compressor with evaporator and water tank are ideal for water cooling.

RIGID Miniature DC Compressors and Compact Cooling Systems and Modules

3. Which is Better, Air Cooling or Liquid Cooling?

There are two options available for EV cooling – with air or water. Air is characterized by low thermal capacity, i.e., it quickly absorbs heat making heat transfer hard to implement. Significant blower noise level and lots of space required are further disadvantages of air-based heat management.

Due to the fact that modern systems are capable of storing more and more energy, and because of the limited space available for Thermal Management in most applications, liquid-based cooling has the ever-growing potential – both for charging stations or electric vehicle portable battery station or Lithium battery station themselves.

Water absorbs heat slower than air, which leads to a lower heat transfer coefficient. Due to this, more heat can be absorbed with water-based cooling. Compared to air, a significantly higher volumetric flow of air is required to achieve similar cooling performance.

RIGID Plate Liquid Chiller DV1920E-P Cooling Performance:

RIGID Water-based Cooling Unit Is An Efficient Way for EV Charging Stations:

To summarize the above, the water cooling process allows large volumes of heat to be transferred effectively at relatively low flows. For this reason, it achieves better continuous cooling performance as compared to air. Given that, As a result, water-based cooling can be particularly effective in cooling systems with high energy storage requirements, such as charging stations and electric vehicles.

To ensure sustainable heat transfer, and in order to achieve the best performance, it is crucial to have a compact, mobile and effective vapor compression liquid cooling systems that are flexible and at the same time stable, coupled with reliable charging connectors.

4. RIGID Successful Thermal Managements

Traditionally, air cooling has been preferred, however, with the fast-paced development of liquid cooling, it has proven more effective since air cooling systems are slower to charge. Additionally, the heat capacity of water is 3,500 times greater than that of air, and water dissipates heat up to ten times more efficiently than air. In addition, pre-filled systems can be used with liquid cooling, which will facilitate the maintenance, expedite any necessary replacements, authorize quick initial installation, and expedite upgrades.

Today, RIGID technology™ has developed a lineup of compact cooling systems including Air cooling, Liquid cooling and Direct Refrigeration. Those small cooling units can be found in many application areas. Among those, thermal battery pack, vehicle inverter, vehicle e-motor charging cable and charging station power electronics.