Liquid Nitrogen Generator Stirling Cooler System

Explore RIGID's pioneering Liquid Nitrogen Generator Stirling Cooler System, meticulously engineered to address market requirements for environmentally sustainable liquid nitrogen manufacturing. This cutting-edge cryogenic device harnesses the inherent nitrogen abundance within Earth's atmosphere, facilitating the condensation of atmospheric air into a precise liquid mixture composed of nitrogen and oxygen.

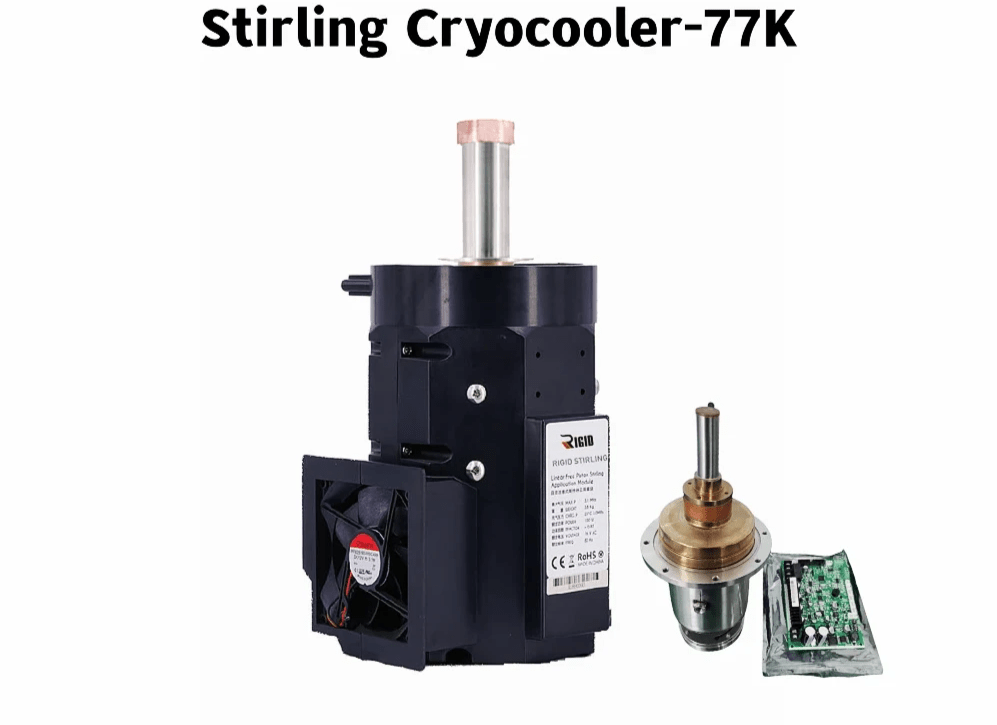

Following an extensive three-year research endeavor, RIGID proudly introduces the RS100 Pro K77, an advanced Stirling cycle cryocooler renowned for its operational prowess at -196℃. This transformative technology not only ensures sustainable nitrogen production but also embodies unwavering reliability and a steadfast commitment to market-driven innovation. Embrace the forefront of cryogenic advancements and participate in the evolution of liquid nitrogen generation with RIGID.

-- How does Stirling Cryocooler 77K work in freeze-fracture devices, and freeze-driers for cryo-electron microscopy – Lab professors all use 60 to 80 Liter of liquid nitrogen per day.

The Stirling Cryocooler operating at 77K plays a crucial role in freeze-fracture devices and freeze-driers used in cryo-electron microscopy. Instead of relying on large quantities of liquid nitrogen (typically 60 to 80 liters per day), this cryocooler offers an efficient and sustainable alternative.

1- Cooling

The Stirling Cryocooler employs a piston and a displacer to cyclically compress and expand helium gas. When the gas is compressed, it becomes hotter, and when it expands, it cools down significantly. This cooling effect is harnessed to achieve and maintain the desired temperature of 77K.

2- Freeze Fracture Devices

In these devices, the Stirling Cryocooler plays a vital role in maintaining a stable and controlled environment at 77K. This low temperature is essential for quickly freezing biological specimens, such as cells or tissues, before they are fractured and examined under an electron microscope. It ensures that the samples remain in their natural state and prevents the formation of ice crystals.

3- Freeze-driers for Cryo-electron Microscopy

Cryo-electron microscopy involves imaging samples at extremely low temperatures to minimize damage and obtain high-resolution images. The Stirling Cryocooler is integrated into freeze-driers to create the necessary low-temperature conditions for rapidly freezing and preserving samples. This process enables researchers to study biological structures in exceptional detail, free from the artifacts associated with traditional sample preparation methods using liquid nitrogen.

Stirling Cryocooler 77K Specification (-196℃)

The RIGID® Stirling cryocooler presents an efficient, dependable, compact, and high-powered cooling solution, catering to the temperature range of 35 to 77 Kelvin. Our Cryocooler series has been meticulously optimized for applications prioritizing SWAP (size, weight, and power) considerations and reliability.

Notably, the RIGID Stirling Cryocooler series exhibits significantly reduced power consumption in comparison to alternative cooling methods, while also demanding minimal maintenance. This makes it an ideal choice for both strategic and industrial applications.

Furthermore, the cryocooler's adaptable design allows for mounting the cold head and pressure wave generator in any orientation. Application scenarios span across semiconductor manufacturing, large-scale infrared detectors, RF receivers and antennas, astronomical telescopes, laser cooling, high-temperature superconductivity, cold traps, and various other domains.

Can We Use Stirling Cryocooler at 77K to Generate Liquid Nitrogen?

A Stirling Cryocooler operating at 77K does not generate liquid nitrogen; instead, it is used to cool down or maintain temperatures at 77 Kelvin. Liquid nitrogen is a cryogenic fluid that is typically produced through a separate process, such as cryogenic distillation of air or the liquefaction of nitrogen gas. The Stirling Cryocooler and liquid nitrogen serve different purposes in cryogenic applications:

1-Stirling Cryocooler at 77K:

The Stirling Cryocooler operates by using a Stirling cycle to create temperature differences, typically cooling down to 77 Kelvin (-196°C or -321°F). It is used to maintain low temperatures for various applications, including cryo-electron microscopy and sample preservation. It does not produce liquid nitrogen but helps maintain a stable low-temperature environment without the need for a continuous supply of liquid nitrogen.

2-Liquid Nitrogen Generation:

Liquid Nitrogen Generation: Liquid nitrogen is generated through a complex industrial process that involves cooling and compressing air to separate and condense nitrogen gas into its liquid form. This process requires specialized equipment and facilities and is typically performed on a much larger scale than the Stirling Cryocooler, which is a compact and portable device for localized cooling.

A Stirling Cryocooler is a device used to achieve and maintain low temperatures, and is commonly used in applications like cryo-electron microscopy and cooling systems for scientific instruments.

Liquid nitrogen, on the other hand, is a cryogenic fluid that is typically produced through an industrial process called cryogenic air separation. This process involves the separation and liquefaction of nitrogen gas from the air. It is a complex and energy-intensive operation performed in large-scale industrial facilities.

If your goal is to produce liquid nitrogen, you would need specialized equipment and infrastructure designed for cryogenic gas separation, not a Stirling Cryocooler. The Stirling Cryocooler is not capable of generating liquid nitrogen; it is used for cooling and maintaining low temperatures in various applications.

Stirling technology reduces the need for liquid nitrogen, making research labs more sustainable and cost-efficient.

In summary, the Stirling Cryocooler operating at 77K serves as an integral component within these scientific instruments, facilitating meticulous temperature regulation, reproducibility, and the effective cryopreservation of biological specimens for cryo-electron microscopy applications. Its deployment notably diminishes reliance on liquid nitrogen, thereby enhancing the sustainability and cost-efficiency of these research laboratory procedures.