Introduction

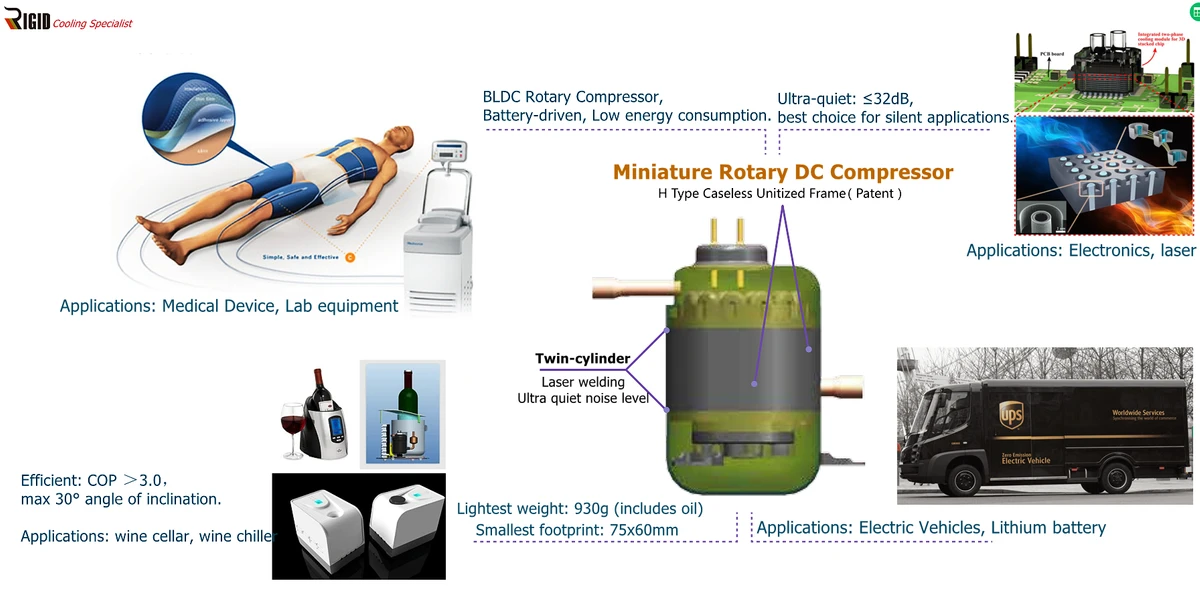

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of refrigeration, oil separators play a crucial role in ensuring efficiency and longevity. A refrigeration oil separator is not just an accessory; it's a vital component that helps maintain the health of your system by effectively separating oil from refrigerant. Understanding how these devices function and recognizing their importance can significantly impact your refrigeration system's performance.

The Importance of Refrigeration Oil Separators

Refrigeration oil separators are essential for maintaining optimal operation in cooling systems. They prevent oil from circulating back into the compressor, which can lead to inefficiencies and potential damage over time. Without a reliable refrigeration oil separator, you risk decreased efficiency and increased operational costs, making it clear that these components are not merely optional.

Understanding the Basics of Oil Separation

At its core, the process of oil separation involves distinguishing between refrigerant and lubricant within a system. This separation is crucial because it ensures that only pure refrigerant circulates through the cooling cycle, maximizing efficiency. Knowing how does a refrigeration oil separator work? is fundamental to appreciating its role in enhancing system reliability and performance.

Why Innovative Solutions Matter

As technology evolves, so do the solutions available for refrigeration systems, including innovative designs for oil separators. RIGID stands at the forefront of this innovation by providing superior options tailored for modern needs in compact cooling applications. Embracing these advancements not only boosts efficiency but also aligns with industry standards—so do you really need an oil separator? The answer is undoubtedly yes if you aim to keep your systems running smoothly.

What is a Refrigeration Oil Separator?

Refrigeration oil separators are essential components in refrigeration systems, designed to effectively separate oil from refrigerant. Their primary purpose is to ensure that oil circulates correctly within the system, preventing potential damage and maintaining efficiency. Understanding how a refrigeration oil separator functions can help you appreciate its importance in optimizing system performance.

Definition and Purpose

A refrigeration oil separator is a device specifically engineered to remove compressor oil from the refrigerant flow in a refrigeration system. By doing so, it ensures that the refrigerant remains clean and free of contaminants that could impair its efficiency. The purpose of this separation process is not only to protect the compressor but also to enhance overall system reliability and longevity.

Key Components Explained

The key components of a refrigeration oil separator include the separator vessel, inlet and outlet ports, and an internal baffle or filter mechanism. The separator vessel holds the mixture of refrigerant and oil, while the inlet port allows this mixture to enter. Once inside, gravity helps separate the heavier oil from the lighter refrigerant, which then exits through the outlet port for further circulation.

The Role in Refrigeration Systems

In refrigeration systems, an efficient refrigeration oil separator plays a critical role by ensuring that adequate lubrication reaches all moving parts without allowing excess oil back into the evaporator or condenser coils. This not only prevents compressor overheating but also maintains optimal cooling efficiency throughout operation. Without an effective separation process, systems may experience reduced performance or even catastrophic failure—leading many to ask: Do you really need an oil separator? The answer is a resounding yes!

How Does a Refrigeration Oil Separator Work?

Understanding how a refrigeration oil separator works is crucial for maintaining the efficiency of refrigeration systems. At its core, this device plays an essential role in ensuring that oil does not accumulate in the refrigerant lines, which can lead to various operational issues. So, let’s dive into the nitty-gritty of this vital component and answer questions like How does a refrigeration oil separator work?

The Separation Process

The separation process begins when the refrigerant-oil mixture enters the refrigeration oil separator. Here, gravity takes center stage; as the mixture flows through, the heavier oil naturally settles at the bottom while lighter refrigerant rises to the top. This simple yet effective mechanism ensures that only purified refrigerant continues through your system, reducing wear and tear on components and improving overall performance.

Efficiency in Oil Recovery

One of the standout features of a refrigeration oil separator is its efficiency in recovering oil from the refrigerant cycle. By effectively separating and returning oil back to the compressor, these separators help maintain optimal lubrication levels within your system. This not only extends equipment lifespan but also minimizes energy consumption—a win-win situation for any operation asking themselves, Do you really need an oil separator?

Impact on System Performance

The impact of a well-functioning refrigeration oil separator on system performance cannot be overstated. When operating efficiently, it helps maintain stable pressures and temperatures within your refrigeration system, leading to improved cooling capacity and energy efficiency. Conversely, if you find yourself pondering How do I know if my oil separator is bad? it’s crucial to address any issues promptly; neglecting this can lead to significant drops in performance and increased operational costs.

Signs Your Oil Separator Needs Replacement

How Do I Know if My Oil Separator is Bad?

Identifying a malfunctioning refrigeration oil separator can be tricky, but there are telltale signs that shouldn’t be ignored. If you notice unusual noises coming from the system or fluctuations in temperature control, these could indicate an issue with your oil separator. Additionally, if you're frequently checking the oil levels and finding them unusually low, it’s time to investigate further—this could point to a failing unit.

Common Indicators of Failure

Several common indicators can signal that your refrigeration oil separator needs replacement or repair. Look out for visible leaks around the unit; any sign of moisture or pooling liquid can suggest a failure in sealing or component integrity. Other red flags include increased energy consumption and reduced cooling efficiency—if your system isn’t performing as it should, it’s likely due to an ineffective oil separation process.

Importance of Regular Maintenance

Regular maintenance of your refrigeration oil separator is crucial for ensuring optimal performance and longevity of your cooling system. By scheduling routine checks and servicing, you can catch potential problems before they escalate into costly repairs or replacements. Remember that neglecting maintenance not only affects the efficiency of your refrigeration system but also impacts its overall lifespan—so don’t skip those service appointments!

Do You Really Need an Oil Separator?

Benefits for Your Refrigeration System

One of the primary benefits of a refrigeration oil separator is its ability to improve energy efficiency by recovering oil that would otherwise be lost in the refrigerant cycle. This recovery process minimizes the risk of compressor damage and helps maintain optimal lubrication throughout your system, ultimately extending its lifespan. Additionally, using an oil separator can lead to reduced operational costs by decreasing energy consumption and minimizing maintenance needs.

Furthermore, a well-functioning refrigeration oil separator contributes to consistent cooling performance by ensuring that lubricants circulate effectively within the system. This means fewer interruptions in service and enhanced reliability during peak operational times. In summary, investing in a quality refrigeration oil separator translates into better overall performance for your refrigeration system.

Consequences of Going Without One

Neglecting to install or maintain a refrigeration oil separator can lead to several detrimental consequences for your cooling system. For starters, without proper separation of lubricants from refrigerants, you may experience increased wear on compressor components due to inadequate lubrication—a situation that could lead to costly repairs or even complete system failure.

Additionally, operating without an effective oil separation mechanism can result in inefficient heat exchange processes within your unit, leading to higher energy bills as your system works overtime to achieve desired temperatures. It’s clear: going without an oil separator isn’t just risky; it’s financially unwise.

Industry Standards and Recommendations

Industry standards strongly advocate for the inclusion of a refrigeration oil separator in any modern cooling setup—especially those involving complex systems with variable loads or multiple compressors. Organizations such as ASHRAE emphasize that proper design and installation are crucial for achieving maximum efficiency in refrigerant systems.

Moreover, manufacturers like RIGID provide innovative solutions tailored specifically for mini compressors and small chillers where space is at a premium but efficiency cannot be compromised. Whether you're asking yourself How does a refrigeration oil separator work? or Where should an oil separator be installed?, aligning with industry recommendations ensures not only compliance but also optimal functionality.

Installation Insights for Refrigeration Oil Separators

Installing a refrigeration oil separator correctly is crucial to ensuring its efficiency and longevity. The placement and installation practices can significantly impact how well the unit performs, which ultimately affects the overall functionality of your refrigeration system. Here’s what you need to know about where to install your oil separator, best practices for optimal performance, and common pitfalls to avoid.

Where Should an Oil Separator Be Installed?

When considering **where an oil separator should be installed**, it's essential to position it as close as possible to the compressor. This proximity allows for efficient oil recovery and minimizes the risk of oil pooling in the refrigerant lines, which can lead to operational inefficiencies. Additionally, ensure that the installation location is accessible for maintenance checks; after all, knowing **how do I know if my oil separator is bad?** becomes much easier when you can reach it without a hassle.

Another critical factor is avoiding areas with excessive vibration or heat sources, as these conditions can adversely affect the performance of your refrigeration oil separator. Proper elevation above surrounding components also helps prevent backflow issues and ensures smooth operation. By following these guidelines on placement, you set up your system for success.

Best Practices for Optimal Performance

To achieve optimal performance from your refrigeration oil separator, adhering to best practices during installation is key. First off, ensure that all connections are secure and leak-free; any leaks could compromise both efficiency and safety in your cooling system. It's also wise to consider using vibration-dampening mounts if you're installing near high-vibration machinery—this prevents unnecessary wear over time.

Regular inspections are another vital practice; keeping an eye on how well your unit operates can help answer questions like **do you really need an oil separator?** The answer is unequivocally yes if you want a reliable and efficient refrigeration system! Make sure you're also familiar with different **refrigeration oil separator types** available in the market so that you choose one that fits seamlessly into your specific setup.

Common Installation Mistakes to Avoid

While installing a refrigeration oil separator might seem straightforward, several common mistakes can lead to headaches down the line. One frequent error is neglecting proper orientation; always check manufacturer guidelines regarding whether it should be installed vertically or horizontally—incorrect positioning could hinder its ability to separate oils effectively!

Another pitfall involves underestimating space requirements; cramming components too close together may restrict airflow or access needed for maintenance tasks later on, making it harder when asking yourself **how does a refrigeration oil separator work?** Lastly, don’t overlook electrical connections—ensure they meet local codes and are compatible with your existing systems.

By steering clear of these missteps and following sound advice regarding placement and maintenance practices, you'll maximize efficiency with your refrigeration oil separator while enhancing overall system reliability.

Types of Refrigeration Oil Separators

When it comes to refrigeration oil separators, understanding the different types available can significantly impact system efficiency and longevity. From traditional designs to advanced technologies, each type serves a specific purpose in ensuring that your refrigeration system operates smoothly. Knowing the various refrigeration oil separator types will help you make informed decisions about which solution best fits your needs.

Overview of Different Types

Refrigeration oil separators come in several varieties, each designed for unique applications and operational requirements. The most common types include centrifugal separators, coalescing filters, and gravity separators. Each type employs distinct mechanisms to separate oil from refrigerant, making it essential to choose one based on your system's specific demands.

Centrifugal separators utilize high-speed rotation to create a force that separates oil from refrigerant effectively. Coalescing filters rely on the principle of merging small droplets into larger ones for easier removal. Gravity separators take advantage of density differences between oil and refrigerant, allowing for natural separation over time.

Comparing Design and Functionality

When comparing design and functionality among refrigeration oil separator types, it's crucial to consider their efficiency and maintenance requirements. Centrifugal separators are known for their high recovery rates but may require more frequent maintenance due to their moving parts. On the other hand, gravity separators are simpler in design but may not be as efficient in recovering oil quickly.

Another factor is space constraints; some designs are bulkier than others, which can affect installation options—where should an oil separator be installed? Smaller systems might benefit from compact coalescing filters that fit snugly into tight spaces while still delivering effective performance.

Ultimately, selecting the right refrigeration oil separator involves weighing these factors against your operational needs and budget constraints—do you really need an oil separator? The answer typically leans toward yes if you want a reliable system with minimal downtime.

RIGID’s Innovative Solutions in the Market

RIGID stands out as a leader in mini compressor innovation within China’s competitive market by offering cutting-edge refrigeration solutions tailored for modern applications. Their line of miniature cooling systems includes advanced refrigeration oil separators designed with superior quality and innovative technology at their core. RIGID's commitment to customer satisfaction ensures that clients receive custom-made solutions that enhance competitiveness without breaking the bank.

By focusing on new technologies in mobile cooling systems, RIGID provides options that not only meet industry standards but also push boundaries in terms of efficiency and performance. Their products are engineered to maximize recovery rates while minimizing energy consumption—ideal features for any business aiming to optimize its operations.

In summary, whether you're considering which refrigeration oil separator type suits your setup or evaluating how does a refrigeration oil separator work?, RIGID offers innovative choices backed by a solid reputation for quality and reliability.

Conclusion

In summary, refrigeration oil separators are vital components for ensuring efficiency and longevity in refrigeration systems. By effectively separating oil from refrigerant, these devices enhance system performance and reduce operational costs. Understanding how does a refrigeration oil separator work is essential for any professional in the industry looking to maximize their equipment's potential.

Maximizing Efficiency with Oil Separators

Maximizing efficiency with an oil separator can lead to significant improvements in your refrigeration system's overall performance. When functioning correctly, a refrigeration oil separator not only recovers valuable lubricants but also minimizes the risk of compressor damage due to inadequate lubrication. Regularly assessing your equipment and knowing how do I know if my oil separator is bad can save you from costly repairs down the line.

Investing in Quality Solutions Matters

Investing in quality solutions like advanced refrigeration oil separators is crucial for maintaining optimal system functionality. While it may be tempting to cut corners, opting for cheaper alternatives can lead to frequent breakdowns and inefficiencies that ultimately cost more over time. RIGID’s innovative designs exemplify the importance of quality; their products are tailored to meet specific client needs while providing reliable performance across various applications.

Future Trends in Refrigeration Technology

Looking ahead, future trends in refrigeration technology indicate a move towards more efficient and environmentally friendly solutions, including advanced types of refrigeration oil separators. Manufacturers will likely focus on integrating smart technologies that monitor performance and predict maintenance needs, improving overall reliability and user experience. As companies like RIGID continue developing cutting-edge designs, understanding where should an oil separator be installed will become increasingly important for maximizing benefits across diverse applications.