Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of commercial refrigeration, the function of compressors is pivotal. These mechanical devices are responsible for circulating refrigerant through the system, ensuring that temperatures remain at optimal levels for food preservation and comfort cooling. Understanding how compressors operate and their impact on overall efficiency is crucial for anyone involved in the refrigeration industry.

Understanding Compressors in Refrigeration

Compressors serve as the heart of refrigeration systems, transforming low-pressure gas into high-pressure gas to facilitate heat exchange. This process not only helps maintain desired temperatures but also plays a significant role in energy consumption and operational costs. As we dive deeper into how compressors function, it's essential to grasp various aspects such as compressor speed, efficiency, and types available in the market.

The Importance of Efficiency in Cooling

Efficiency is a key factor when considering cooling solutions; after all, no one wants to pay exorbitant energy bills just to keep things cool! An efficient compressor can significantly reduce energy consumption while maintaining performance levels that meet specific cooling needs. Questions often arise regarding whether higher RPM translates to better pump efficiency—this is where understanding compressor dynamics becomes vital.

Exploring Different Types of Compressors

There are several types of compressors utilized in commercial refrigeration, each with its own set of advantages and disadvantages. For instance, reciprocating compressors are widely known for their reliability and capacity but may not always be the most efficient choice depending on application demands. By examining various models like scroll compressors or innovative designs from RIGID, we can better determine which compressor is more efficient for specific scenarios while addressing how we can increase the efficiency of our compressors overall.

The Role of Compressors in Commercial Refrigeration

Compressors are the unsung heroes of commercial refrigeration, playing a crucial role in maintaining optimal temperatures for various applications. They ensure that perishable goods remain fresh and safe by regulating temperature effectively. Understanding the function of compressors in commercial refrigeration is vital for anyone involved in this industry.

How Compressors Maintain Temperature

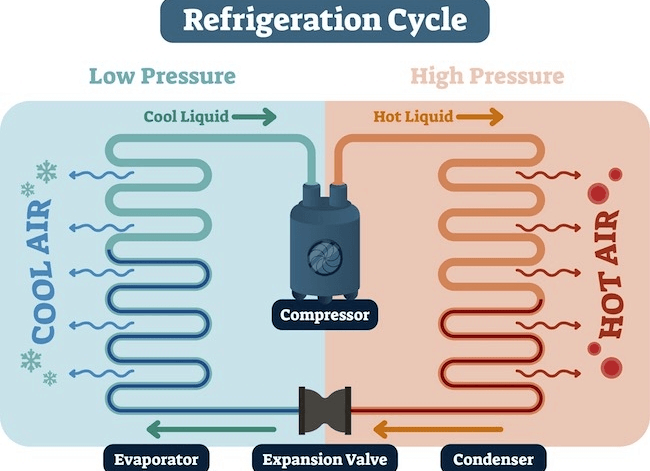

Compressors maintain temperature by compressing refrigerant gas, which subsequently increases its pressure and temperature. This process allows the refrigerant to flow through the system, absorbing heat from the environment and releasing it outside. By continuously cycling refrigerant, compressors keep commercial refrigeration systems running smoothly and efficiently, ensuring that products stay at their desired temperatures.

The Thermodynamic Cycle Explained

The thermodynamic cycle is essential for understanding how compressors function within refrigeration systems. It involves four main stages: compression, condensation, expansion, and evaporation. During compression, low-pressure gas is transformed into high-pressure gas; as it moves through the condenser, it releases heat and turns into a liquid before expanding to reduce pressure and cool down again—ultimately evaporating to absorb heat from the refrigerated space.

Importance of Proper Sizing and Selection

Choosing the right compressor size is critical for achieving maximum efficiency in cooling applications. An oversized compressor can lead to rapid cycling, reducing its lifespan and increasing energy consumption—while an undersized unit may struggle to maintain desired temperatures effectively. Therefore, understanding which compressor is more efficient based on specific operational needs can significantly impact overall performance; this includes evaluating options like reciprocating compressors versus other types.

Is Higher RPM Always Better for Efficiency?

Analyzing Compressor Speed and Efficiency

The function of compressors in commercial refrigeration relies heavily on their operational speed. While it may seem intuitive that faster speeds yield higher pump efficiency, this isn't universally true. In fact, optimal efficiency often occurs at specific RPMs tailored to the application; exceeding these speeds can lead to increased wear and tear on components, reduced lifespan, and even higher energy consumption.

Is the higher the RPM of a compressor the higher the pump efficiency? Not necessarily! Many factors come into play when determining overall performance, including design characteristics and load conditions. Thus, it's crucial for operators to analyze not just speed but also other parameters that influence compressor effectiveness.

How Does Compressor Speed Affect Flow Rate?

Understanding how compressor speed affects flow rate is essential for optimizing performance in commercial refrigeration systems. Generally speaking, as you increase a compressor's RPM, you also increase its flow rate—up to a point. Beyond that threshold, diminishing returns kick in; additional speed may not yield proportional increases in flow rate or could even lead to inefficiencies.

For instance, reciprocating compressors are designed with specific operating ranges where they perform best. If operators push these machines beyond their ideal RPMs in an attempt to boost flow rates or cooling capacities, they may inadvertently compromise system efficiency instead of enhancing it.

Finding the Balance Between Speed and Performance

Finding the balance between speed and performance is key when evaluating which compressor is more efficient for your needs. It’s not just about cranking up those RPMs; rather, it's about aligning operational parameters with system requirements for optimal results. Achieving this balance involves careful consideration of various factors such as load conditions, ambient temperatures, and desired cooling output.

How can I increase the efficiency of my compressor? Start by assessing your current setup—ensure that your chosen compressor operates within its recommended range while considering innovative solutions like those offered by RIGID mini compressors. With their advanced designs tailored for mobile cooling applications and custom-made solutions based on client needs, RIGID exemplifies how technology can enhance both performance and energy savings in commercial refrigeration.

Types of Compressors: Which is More Efficient?

When it comes to commercial refrigeration, understanding the various types of compressors is essential for optimizing performance and efficiency. The function of compressors in commercial refrigeration is pivotal, as they are responsible for maintaining the desired temperature within refrigeration systems. Choosing the right type can significantly impact the overall efficiency and effectiveness of cooling solutions.

Overview of Common Compressor Types

There are several common types of compressors used in commercial refrigeration, each with its unique characteristics and applications. The most prevalent types include reciprocating compressors, scroll compressors, and rotary compressors. Each type has its advantages and disadvantages regarding efficiency, noise levels, maintenance needs, and suitability for specific applications.

Reciprocating compressors are known for their robust design and ability to handle varying loads effectively. However, they may not always be the most efficient choice in every scenario. Understanding which compressor is more efficient depends on factors such as application requirements and operational conditions.

Comparing Reciprocating vs. Scroll Compressors

When comparing reciprocating compressors with scroll compressors, it's essential to consider their operational mechanics and efficiency ratings. Reciprocating compressors use pistons to compress refrigerant gas; they often provide high pressure but can be less efficient at lower speeds due to increased friction losses. On the other hand, scroll compressors utilize two spiral-shaped elements that compress refrigerant continuously, leading to a smoother operation with higher efficiency.

Is the higher RPM of a compressor always indicative of better pump efficiency? Not necessarily! While higher RPMs can increase flow rates initially—how does compressor speed affect flow rate?—it also leads to increased wear and tear over time if not managed properly.

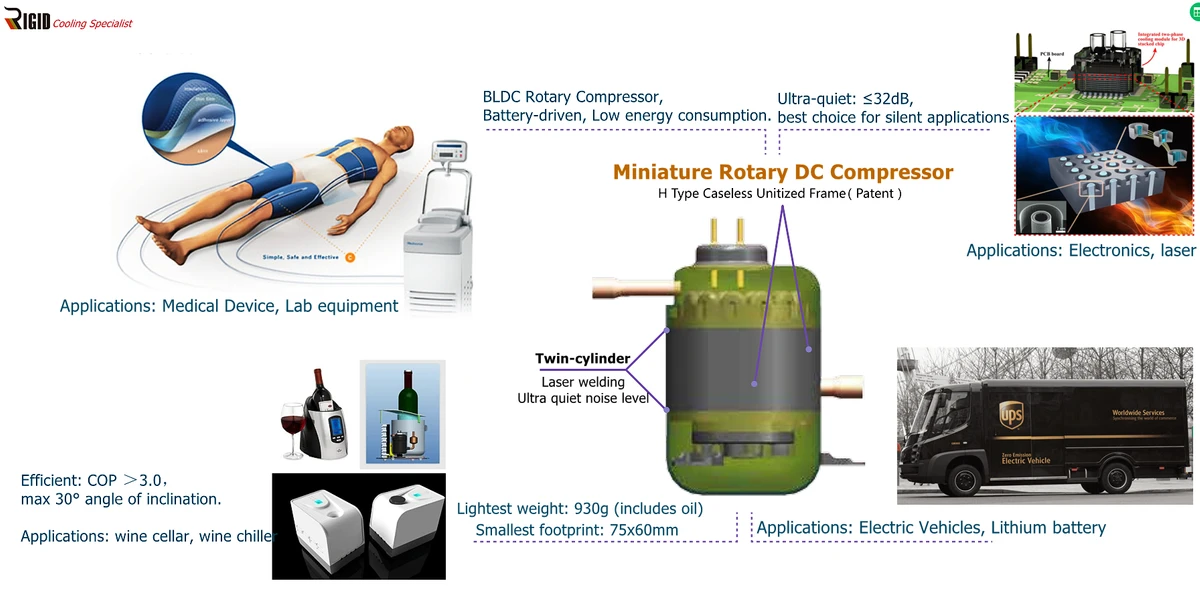

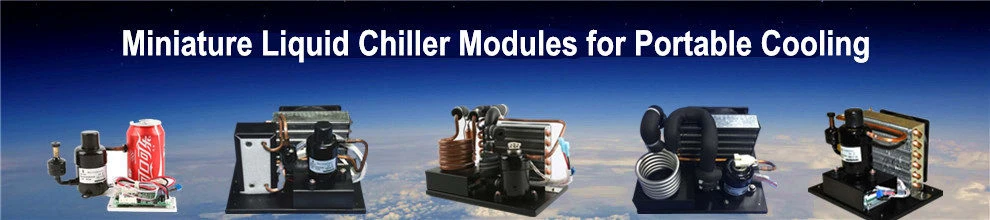

The Rise of RIGID in Miniature Cooling Solutions

RIGID has emerged as a leader in mini compressor innovation in China, making waves with their compact cooling systems designed for diverse applications like micro refrigeration and air conditioning. Their focus on superior design coupled with uncompromising quality positions them uniquely within the industry as pioneers in miniature cooling solutions. As businesses look for ways to enhance their competitiveness while managing budgets effectively, RIGID's custom-made solutions become increasingly appealing.

With an array of products such as mini chillers and Stirling coolers tailored specifically for micro applications, RIGID demonstrates how innovation can lead to improved efficiency across various sectors. How can I increase the efficiency of my compressor? By considering options like those offered by RIGID that prioritize both performance and adaptability based on client needs!

Tips to Increase Compressor Efficiency

Maximizing the efficiency of compressors in commercial refrigeration is crucial for reducing operational costs and enhancing overall system performance. By implementing regular maintenance practices, optimizing system designs, and making informed choices about compressor types, businesses can significantly improve energy efficiency. Understanding the function of compressors in commercial refrigeration is essential to achieve these goals.

Regular Maintenance Practices

Regular maintenance practices are vital for ensuring that your compressor operates at peak efficiency. Routine checks on components such as filters, refrigerant levels, and electrical connections can prevent issues that may lead to inefficiencies. Additionally, addressing minor repairs promptly can save you from costly breakdowns and extend the lifespan of your equipment.

For example, keeping coils clean allows for better heat exchange, which directly influences how effectively your compressor functions. Neglecting these tasks can lead to reduced performance, prompting the question: Is the higher the RPM of a compressor the higher the pump efficiency? The answer lies in understanding that while speed plays a role in performance, it’s not the only factor; proper maintenance is equally critical.

Lastly, scheduling professional inspections at least once a year will help identify potential problems before they escalate. This proactive approach ensures that your compressor runs smoothly and efficiently throughout its operational life.

Optimizing System Design and Layout

Optimizing system design and layout can drastically improve compressor efficiency by reducing unnecessary strain on components. A well-designed refrigeration system minimizes bends in piping and optimizes refrigerant flow paths; this directly impacts how does compressor speed affect flow rate? The smoother the flow path, the less energy is required for circulation.

Additionally, placing compressors closer to evaporators reduces pressure drops and enhances overall system performance. In environments where space is a premium or where noise reduction is essential, RIGID’s miniature cooling solutions offer innovative options tailored to specific needs without compromising efficiency or effectiveness.

Finally, considering insulation quality within your design helps maintain temperature stability throughout your refrigeration system. By minimizing thermal losses through effective insulation techniques, you ensure that your compressors work less hard—ultimately leading to increased longevity and lower operating costs.

How Can I Increase the Efficiency of My Compressor?

To increase the efficiency of your compressor effectively requires a multifaceted approach tailored to specific operational needs. Start by evaluating whether you’re using an appropriate type of compressor for your application; for instance, reciprocating compressors may be more suitable than others depending on capacity requirements or space constraints.

Another key factor involves monitoring operating conditions closely—ensuring optimal refrigerant charge levels will help maintain ideal pressure ratios within systems while preventing overworking conditions that detract from pump efficiency gains. It’s also worth exploring variable-speed drives (VSDs), which allow compressors to adjust their speed based on demand rather than running at fixed RPMs all day long.

Lastly, investing time into employee training regarding best practices around operation can yield significant benefits too! Knowledgeable staff members who understand both how does compressor speed affect flow rate? And why proper usage matters are invaluable assets when striving toward improved energy savings over time—all while keeping an eye out for which compressor is more efficient based on evolving technologies emerging within this dynamic market landscape!

Innovative Solutions in Commercial Refrigeration

In the ever-evolving landscape of commercial refrigeration, innovative solutions are crucial for enhancing efficiency and performance. With advancements in technology, mini compressors are becoming more prevalent, offering significant benefits in terms of space-saving and energy efficiency. Understanding the function of compressors in commercial refrigeration is essential for businesses looking to optimize their operations.

The Future of Mini Compressor Technology

The future of mini compressor technology looks promising, with a focus on compact design and high efficiency. These small yet powerful units can provide effective cooling solutions without taking up much space, making them ideal for various applications. As businesses increasingly seek ways to reduce their carbon footprint and energy costs, the demand for efficient cooling systems will only grow.

However, a common question arises: Is the higher the RPM of a compressor the higher the pump efficiency? While higher RPMs can increase flow rates initially, they may not always translate to better overall efficiency. Understanding how compressor speed affects flow rate is crucial; it allows users to find that sweet spot where performance meets energy savings.

RIGID's Role in Advancing Refrigeration Solutions

RIGID stands out as a leader in mini compressor innovation within China’s competitive market landscape. Their commitment to capturing new technologies has resulted in superior designs that cater specifically to mobile and compact cooling systems. With an unwavering focus on quality and customer satisfaction, RIGID has become synonymous with cutting-edge micro cooling technology.

By prioritizing clients’ budgets while boosting competitiveness through advanced solutions, RIGID exemplifies how innovative companies can shape the future of refrigeration. Their range includes mini compressors, small chillers, direct cooling systems, and even micro DC air conditioning units tailored for various needs. This adaptability positions RIGID as an essential player when considering which compressor is more efficient for specific applications.

Custom-Made Solutions Tailored to Your Needs

One size does not fit all when it comes to refrigeration solutions; that's where custom-made options come into play! RIGID understands that each client has unique requirements that demand tailored approaches—whether it’s adjusting system layouts or optimizing component sizes for enhanced performance. This flexibility allows businesses to explore how they can increase the efficiency of their compressors while meeting specific operational demands.

Moreover, engaging directly with customers ensures that RIGID can create bespoke solutions that align perfectly with their needs—an invaluable asset in today’s competitive environment! By leveraging advanced technologies and expert insights into The Function of Compressors in Commercial Refrigeration, clients will find themselves empowered with tools designed specifically for their success.

Conclusion

In the realm of commercial refrigeration, understanding the function of compressors is crucial for effective temperature management and energy efficiency. Compressors are the heart of cooling systems, playing a pivotal role in maintaining desired temperatures while minimizing energy consumption. As we’ve explored, various factors influence compressor performance, including speed, type, and maintenance practices.

Key Takeaways on Compressor Functions

The function of compressors in commercial refrigeration is to compress refrigerant gas and circulate it through the system to facilitate cooling. This process not only maintains optimal temperatures but also directly impacts energy efficiency—key for businesses aiming to reduce operational costs. Among the diverse types available, choosing between options like reciprocating compressors or newer technologies can significantly affect overall performance.

The Importance of Choosing Right Technology

When considering which compressor is more efficient for your specific needs, it’s essential to evaluate both speed and design. Is the higher RPM of a compressor always indicative of better pump efficiency? Not necessarily; while higher speeds can increase flow rates initially, they may lead to inefficiencies in other areas if not properly balanced with system requirements.

Future Trends in Commercial Refrigeration Industry

Innovations like those from RIGID are paving the way for advanced miniature cooling solutions that promise greater efficiency and adaptability in commercial refrigeration applications. As we look ahead, trends indicate a shift toward more compact designs that deliver high performance without compromising on quality or energy use. Custom-made solutions tailored to individual needs will likely become standard practice as businesses seek competitive advantages through enhanced cooling technologies.