Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of refrigeration, the oil separator function plays a pivotal role in ensuring systems operate smoothly and efficiently. Understanding how a Refrigerant Oil Separator works is essential for anyone involved in the design or maintenance of cooling systems. This introduction will delve into the basics, importance, and applications of oil separators across various industries.

Understanding the Basics of Oil Separators

At its core, an oil separator is designed to remove excess oil from refrigerants circulating within a system. The oil separator function in refrigeration systems helps maintain optimal performance by preventing oil from accumulating where it shouldn't be, which can lead to inefficiencies and potential failures. For those seeking more technical insights, resources like Oil Separator in Refrigeration System PDF provide detailed diagrams and explanations of these crucial components.

Importance of Refrigerant Oil Separators

Refrigerant Oil Separators are vital for maintaining system efficiency and longevity. By ensuring that only the necessary amount of oil circulates with the refrigerant, these separators help optimize energy consumption while minimizing wear on key components. The significance of understanding the oil separator function in refrigeration system diagrams cannot be overstated; they illustrate how essential these devices are to reliable operation.

Applications in Various Industries

Oil separators find their place across multiple sectors including food processing, pharmaceuticals, and HVAC systems. Each industry benefits from effective management of refrigerants and oils to enhance performance and reduce operational costs. From industrial settings utilizing an Industrial Oil Separator function in refrigeration systems to small-scale applications needing compact solutions, it's clear that these devices cater to diverse needs while promoting sustainability.

What is an Oil Separator?

Oil separators are crucial components in refrigeration systems, designed to separate oil from refrigerant gas. This separation process ensures that the refrigerant can flow freely through the system without being hindered by excess oil, which can lead to inefficiencies and potential damage. Understanding the oil separator function is essential for maintaining optimal performance in various refrigeration applications.

The Role of Oil Separators in Refrigeration

The primary role of oil separators in refrigeration is to maintain a balanced and efficient system. By removing excess oil from the refrigerant gas, these devices help prevent compressor flooding, which could otherwise result in decreased efficiency and increased wear on mechanical components. In essence, an effective refrigerant oil separator ensures that the system operates smoothly, enhancing overall reliability and longevity.

The importance of proper oil management cannot be overstated; it directly impacts energy consumption and operational costs. An inadequately functioning oil separator can lead to increased energy usage as compressors work harder to overcome resistance caused by excess oil. Therefore, understanding the role of these separators is vital for anyone involved in refrigeration system design or maintenance.

Oil Separator Function in Refrigeration Systems

The oil separator function within refrigeration systems involves a series of processes aimed at extracting lubricating oils from the refrigerant before it returns to the compressor. Typically located between the evaporator and compressor units, these separators utilize gravity or centrifugal force to separate lighter refrigerants from heavier oils effectively. This function is critical; if too much oil returns to the compressor, it can cause significant operational issues.

In terms of design specifications outlined in resources like Oil Separator Function in Refrigeration System PDF, various models exist tailored for different applications and capacities. Understanding these specifications helps engineers select appropriate systems based on their unique requirements—be it for industrial settings or smaller commercial units requiring precise temperature control.

Moreover, visual aids like Oil Separator Function in Refrigeration System Diagram provide clarity on how these components interact within a broader system context, illustrating their placement and operational dynamics effectively.

Differences Between Various Oil Separators

Not all oil separators are created equal; there are several types tailored for specific applications within refrigeration systems. For instance, some industrial environments may require advanced designs capable of handling larger volumes or specific fluid characteristics—these are often referred to as industrial oil separator functions within refrigeration systems. Conversely, smaller systems might rely on simpler models that still efficiently perform necessary separation tasks without added complexity.

Key differences among these separators include their method of operation (gravity-based vs centrifugal), capacity ratings, and construction materials used—all factors influencing their efficiency and suitability for particular installations. When selecting an appropriate model based on application needs outlined in resources such as Oil Separator Function in Refrigeration System PDF, it's essential to consider both performance metrics and environmental conditions where they will be deployed.

Ultimately, understanding these differences not only aids engineers during installation but also informs ongoing maintenance practices—ensuring that each component continues performing its designated role effectively over time.

The Working Mechanism of Oil Separators

Understanding how oil separators function is essential for optimizing refrigeration systems. These devices play a crucial role in managing refrigerant oil, ensuring that it circulates properly within the system while preventing excessive oil accumulation in the evaporator or compressor. By maintaining the right balance of refrigerant and oil, the overall efficiency and longevity of refrigeration systems can be significantly enhanced.

How Oil Separator Function Operates

The oil separator function operates through a series of processes designed to separate oil from refrigerant gas effectively. As the refrigerant circulates through the system, it carries with it a certain amount of lubricating oil necessary for compressor operation. The separator uses various physical principles, such as gravity and centrifugal force, to extract and reclaim this oil, directing it back into the compressor while allowing clean refrigerant gas to continue its journey through the system.

In essence, when refrigerant vapor enters an Oil Separator in a refrigeration system, it encounters baffles or mesh screens that induce turbulence. This turbulence causes heavier oil particles to coalesce and settle at the bottom of the separator. From there, these separated oils are returned to their designated locations within the system via return lines or channels designed specifically for this purpose.

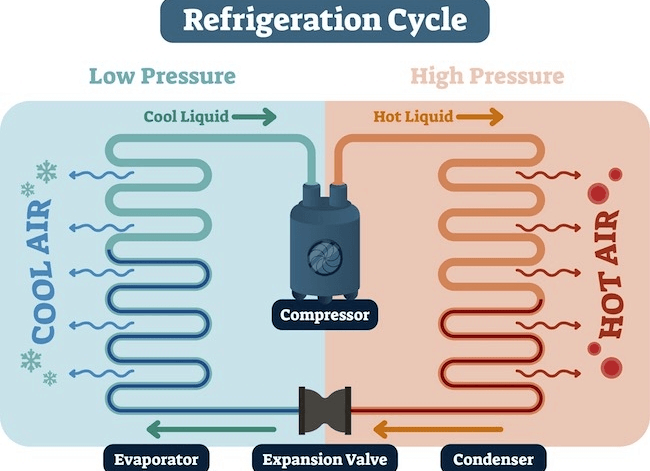

Understanding Oil Separator Function in Refrigeration System Diagram

A well-structured diagram illustrating the oil separator function in refrigeration systems can provide invaluable insights into how these components interact within larger setups. Such diagrams typically showcase key elements like compressors, evaporators, condensers, and piping layouts alongside an Oil Separator function representation that highlights its pivotal role in maintaining fluid dynamics.

In these diagrams, you will often see arrows indicating flow directions for both refrigerants and oils. The visual representation helps clarify how separated oils are routed back into compressors while ensuring that only purified refrigerants circulate throughout other parts of the system. For those seeking detailed technical information on this topic, resources like Oil Separator Function in Refrigeration System PDF can offer comprehensive explanations coupled with visual aids.

Key Components of a Refrigerant Oil Separator

Understanding key components is vital when discussing Industrial oil separator functions in refrigeration systems since each part contributes significantly to overall performance and reliability. Common components include housing units where separation occurs, internal baffles that facilitate turbulence creation for efficient separation, and return lines designed for transporting reclaimed oils back into circulation.

Additionally, many modern Refrigerant Oil Separators come equipped with sensors that monitor pressure differentials and ensure optimal functioning conditions are maintained at all times. These sensors can trigger alarms or automatic adjustments if they detect any anomalies—ensuring smoother operations without manual intervention required frequently.

As we explore further into maintenance practices later on, recognizing these key components will help users troubleshoot issues more effectively by identifying which parts may need attention or replacement over time.

Benefits of Using Oil Separators

Oil separators play a crucial role in enhancing the overall functionality and efficiency of refrigeration systems. By effectively managing oil within these systems, they ensure optimal performance and longevity. This section will explore the benefits of oil separators, focusing on their efficiency, cost-saving potential, and environmental impact.

Enhancing Efficiency and Performance

The oil separator function is vital for maintaining high efficiency in refrigeration systems. By separating the refrigerant from the lubricating oil, these devices prevent oil from circulating in areas where it can hinder heat transfer. Consequently, a well-functioning Refrigerant Oil Separator ensures that cooling systems operate at peak performance levels while minimizing energy consumption.

Incorporating an oil separator function in refrigeration system design can lead to significant improvements in thermal efficiency. Systems equipped with effective oil separation technology experience reduced compressor wear and tear, translating into longer equipment life. This not only enhances performance but also reduces downtime for maintenance or repairs—an essential factor for businesses relying on consistent cooling solutions.

Moreover, an industrial oil separator function in refrigeration systems allows for better control over lubrication levels throughout the system. This precise management helps maintain optimal operating conditions, ultimately resulting in enhanced system reliability and performance consistency over time.

Cost Savings through Proper Oil Management

Investing in an efficient oil separator can yield substantial cost savings through proper oil management practices. By preventing excessive amounts of refrigerant oil from circulating within the system, businesses can reduce energy costs associated with inefficient operation. The ability to maintain optimal lubrication levels translates into lower operational expenses over time.

Furthermore, utilizing an effective Refrigerant Oil Separator minimizes the need for frequent maintenance or replacement parts due to reduced wear on critical components like compressors. Fewer breakdowns mean less unplanned downtime and lower labor costs associated with repairs—making this investment financially sound for many industries reliant on refrigeration technology.

Additionally, having access to resources such as Oil separator function in refrigeration system PDF documents provides valuable information on best practices for managing costs related to oil use and maintenance strategies. Armed with knowledge about their specific applications and needs through these resources can help businesses maximize their returns on investment while ensuring efficient operation.

Reducing Environmental Impact

The environmental benefits of using proper oil separators cannot be overstated; they play a significant role in reducing waste and improving sustainability efforts across various industries. By effectively separating refrigerants from oils, these devices minimize leaks that could otherwise contribute to harmful emissions or pollution—a major concern as regulations around environmental impact become more stringent worldwide.

Moreover, utilizing an industrial oil separator function in refrigeration systems aids in responsible resource management by ensuring that oils are reused rather than disposed of improperly or wasted altogether. This promotes a circular economy approach where materials are continually cycled back into use rather than contributing to landfill waste or environmental degradation.

Finally, companies like RIGID are leading the charge by developing innovative mini compressor solutions that incorporate advanced refrigerant management technologies within their products—further emphasizing their commitment to sustainability without compromising performance quality or client satisfaction! Investing in cutting-edge technologies not only meets current market demands but also aligns with growing consumer expectations regarding eco-friendly practices.

Real-World Applications

The application of oil separators in various industries showcases their versatility and importance. From refrigeration systems to industrial processes, the oil separator function plays a crucial role in maintaining efficiency and reducing costs. This section will delve into real-world applications, highlighting innovative solutions and the benefits across different sectors.

Case Study: RIGID and Their Innovative Solutions

RIGID is a mini compressor innovation leader based in China, known for its cutting-edge technologies in mobile and compact cooling systems. Their Refrigerant Oil Separator designs demonstrate how effective oil management can enhance performance while minimizing environmental impact. By focusing on custom solutions tailored to clients' budgets, RIGID has established itself as a pioneer in micro cooling, showcasing the vital oil separator function within their refrigeration systems.

Their approach emphasizes superior design and uncompromising quality, which is evident in their range of products like mini compressors and small chillers. These innovations not only improve efficiency but also extend the lifespan of refrigeration systems by ensuring optimal oil circulation through effective oil separator function mechanisms. RIGID's commitment to customer satisfaction has resulted in a growing list of satisfied clients who benefit from tailored refrigeration solutions that incorporate advanced oil separator functions.

Industrial Oil Separator Function in Refrigeration Systems

In industrial settings, the oil separator function is critical for maintaining the health of refrigeration systems. An effective industrial oil separator ensures that excess refrigerant oil is removed from the system without compromising performance or efficiency. The use of an Oil Separator Function in Refrigeration System PDF can provide detailed insights into how these components work together to optimize system operations.

The integration of an industrial oil separator into refrigeration systems enables better control over refrigerant flow and enhances overall energy efficiency. By preventing excessive buildup of refrigerant oils within the system, these separators contribute to reduced maintenance costs and downtime—a win-win for any operation looking to maximize productivity while minimizing expenses related to repairs or replacements caused by poor lubrication practices.

Furthermore, understanding the Oil Separator Function in Refrigeration System Diagram allows engineers and technicians to visualize how these components interact within larger cooling configurations—making it easier to implement best practices for installation and maintenance.

Sectors Benefiting from Effective Oil Separator Use

Various sectors significantly benefit from effective use of refrigerant oil separators due to their ability to enhance operational efficiency while reducing environmental impacts. Industries such as food processing, pharmaceuticals, and chemical manufacturing rely on precise temperature control provided by robust refrigeration systems equipped with efficient oil separators. The importance of proper management through an Industrial Oil Separator Function in Refrigeration System cannot be overstated; it directly correlates with product quality and compliance with regulatory standards.

Additionally, sectors involved in transportation—like refrigerated trucking—also leverage advanced refrigerant technologies that include sophisticated oil separators designed for mobile applications. These innovations ensure that cargo remains at optimal temperatures during transit while minimizing energy consumption—demonstrating yet again how integral the Oil Separator Function is across various industries.

Moreover, businesses are increasingly aware that investing in high-quality refrigeration solutions equipped with reliable oil separators not only improves performance but also contributes positively towards sustainability efforts by reducing waste associated with coolant leaks or inefficient machinery operation.

Maintenance and Troubleshooting

Maintaining the efficiency of your Refrigerant Oil Separator is crucial for optimal performance in refrigeration systems. Regular maintenance not only prolongs the lifespan of the oil separator function but also ensures that your system operates smoothly, preventing costly downtimes. By implementing a proactive maintenance strategy, you can keep your industrial oil separator function running at peak performance.

Regular Maintenance Tips for Longevity

To ensure the longevity of your oil separator function in refrigeration systems, regular inspections are essential. Check for any signs of wear and tear, such as leaks or blockages, which could hinder the oil separator function in refrigeration system diagram performance. Additionally, schedule periodic cleaning to remove accumulated debris and contaminants that may affect efficiency.

Lubrication is another key aspect; ensure that all moving parts are adequately lubricated to reduce friction and wear. Keeping an eye on refrigerant levels will also help maintain proper functioning; low levels can lead to inadequate oil return to the compressor, negatively impacting overall system performance. Lastly, always refer to an Oil Separator Function in Refrigeration System PDF for specific guidelines tailored to your unit.

Common Issues and How to Solve Them

Even with diligent maintenance, issues can arise with oil separators in refrigeration systems. One common problem is excessive pressure buildup due to blockages or improper drainage; this can be resolved by inspecting and clearing any obstructions in the lines. If you notice a significant drop in efficiency or unusual noises from the compressor, it could indicate a malfunctioning oil separator function—addressing this promptly is crucial.

Another frequent issue involves contamination of refrigerants with excess oil; this can lead to poor cooling performance and increased energy consumption. To combat this situation, regularly monitor refrigerant quality and consider using filtration devices designed specifically for industrial oil separator functions within refrigeration systems. Always consult documentation like an Oil Separator Function in Refrigeration System PDF when troubleshooting specific issues.

When to Seek Professional Assistance

While many maintenance tasks can be handled internally, there are times when seeking professional assistance becomes necessary for maintaining effective operation of your refrigerant oil separator. If you encounter persistent problems that you can't resolve through standard troubleshooting methods—such as recurring leaks or significant pressure anomalies—it's wise to call in experts who specialize in industrial oil separators.

Additionally, if you're considering upgrades or modifications—like integrating advanced technology from companies like RIGID—it’s best to consult professionals who understand both existing systems and new innovations thoroughly. They can provide insights into custom solutions tailored specifically for your needs while ensuring compatibility with current setups based on comprehensive knowledge drawn from resources like an Oil Separator Function in Refrigeration System PDF.

Remember: investing time and resources into proper maintenance today will pay off tomorrow by minimizing downtime and maximizing efficiency!

Conclusion

In wrapping up our exploration of oil separators, it’s clear that understanding the oil separator function is crucial for optimizing refrigeration systems. The Refrigerant Oil Separator plays a vital role in maintaining system efficiency and performance, ensuring that oil management is both effective and environmentally friendly. As industries continue to evolve, the significance of these components in refrigeration systems cannot be overstated.

Key Takeaways on Oil Separator Functions

The oil separator function in refrigeration systems is essential for separating refrigerant from lubricating oil, which ensures smooth operation and enhances system longevity. By utilizing an industrial oil separator function in refrigeration systems, businesses can prevent issues such as compressor damage and inefficient cooling performance. Moreover, knowledge about the different types of oil separators and their specific applications helps companies select the right solution tailored to their operational needs.

Future Trends in Refrigeration Technology

As we look ahead, innovations in refrigeration technology will likely focus on increasing energy efficiency and reducing environmental impact through advanced oil separation techniques. The development of smart refrigerant management systems may integrate real-time monitoring with sophisticated algorithms to optimize the oil separator function dynamically. Additionally, companies like RIGID are at the forefront of these advancements by providing custom solutions that align with modern demands for compactness and efficiency in cooling applications.

The Importance of Custom Solutions in Oil Separation

Custom solutions for oil separation are becoming increasingly important as industries seek to optimize their operations while adhering to strict environmental standards. Tailoring an industrial oil separator function in refrigeration systems allows businesses to meet specific requirements based on their unique operational contexts, leading to enhanced performance and cost savings. RIGID exemplifies this approach by working closely with clients to develop innovative mini compressor designs that incorporate effective refrigerant oil separators tailored to diverse applications.