Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

Air cooled condensing units are an essential component in refrigeration systems, providing efficient cooling for commercial and industrial applications. Understanding the function and benefits of air cooled condensing units is crucial for making informed decisions about refrigeration solutions. When comparing air cooled vs. water cooled condensing units, it's important to consider factors such as efficiency, environmental impact, and practical installation and maintenance considerations. Additionally, pricing air cooled condensing units can vary based on size, capacity, and advanced features.

Understanding Air Cooled Condensing Units

Air cooled condensing units are responsible for removing heat from the refrigerant in a refrigeration system by transferring it to the surrounding air. This process is essential for maintaining optimal temperatures in cold storage facilities, food processing plants, and other industrial settings.

The Benefits of Air Cooled Condensing Units

One of the key benefits of air cooled condensing units is their compact design and ease of installation, making them a cost-effective solution for various applications. They also offer energy efficiency and reliable performance in maintaining consistent temperatures for perishable goods.

Making the Switch: Air Cooled vs. Water Cooled Condensing Units

When deciding between air cooled and water cooled condensing units, it's important to weigh factors such as water usage, environmental impact, maintenance requirements, and overall efficiency to determine which option best suits specific operational needs.

The Function of Air Cooled Condensing Units

The primary function of an air cooled condensing unit is to remove heat from the refrigerant by using a fan to draw ambient air over the condenser coils where heat exchange occurs.

Pricing Air Cooled Condensing Units

The pricing of air cooled condensing units can vary based on factors such as capacity, advanced features like variable speed compressors or smart controls, as well as brand reputation and warranty offerings.

What are Air Cooled Condensing Units?

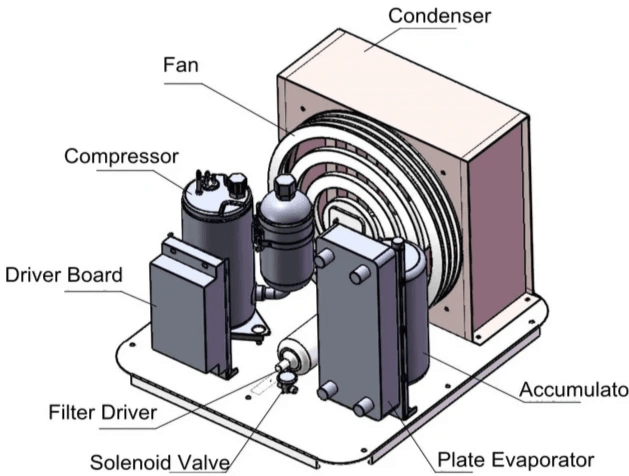

Key components and working principle

An air cooled condensing unit consists of a compressor, condenser coil, fan, and expansion valve. The compressor pumps refrigerant gas to the condenser coil, where it releases heat and turns into a liquid. The fan then blows air over the coil to cool the refrigerant, which is then sent to the evaporator.

An air-cooled condensing unit is a crucial component in refrigeration systems, as it efficiently removes heat from the refrigerant, allowing it to be cycled back through the system. The compressor plays a key role in pressurizing the refrigerant gas and moving it through the condenser coil, where the heat exchange process takes place. The fan then works to dissipate this heat by blowing air over the coil, ensuring that the refrigerant is adequately cooled before being sent to the evaporator.

Advantages in refrigeration systems

Air cooled condensing units offer several advantages in refrigeration systems, including lower installation costs due to the absence of water lines and cooling towers. They also require less maintenance and have a smaller environmental footprint compared to water-cooled units.

Additionally, air-cooled condensing units are more flexible in terms of placement, as they do not require proximity to a water source. This makes them ideal for locations where access to water is limited or where space is at a premium. Furthermore, these units are easier to relocate if needed, providing businesses with the freedom to reconfigure their refrigeration systems as their needs evolve.

Common applications in commercial and industrial settings

Air cooled condensing units are known for their ease of installation and low maintenance requirements, making them a popular choice for businesses looking to minimize downtime and operating costs. Their compact design also makes them ideal for facilities with limited space, providing a practical solution for refrigeration and cooling needs without sacrificing valuable square footage. In addition, air cooled condensing units are often favored for their energy efficiency, helping businesses reduce their environmental impact while keeping operational expenses in check.

Air Cooled vs. Water Cooled Condensing Units

A comparative analysis of efficiency and performance

When comparing air cooled condensing units to water cooled ones, it's important to consider the efficiency and performance of both systems. Air cooled units are known for their energy efficiency and lower operational costs, making them a popular choice for many refrigeration applications. On the other hand, water cooled units may offer higher efficiency in certain conditions but come with increased water usage and maintenance requirements.

Furthermore, air cooled condensing units are typically easier to install and require less space compared to water cooled units. This makes them a more practical choice for facilities with limited space or where the installation of a water cooling system may be challenging. Additionally, air cooled units do not require access to a water source, making them suitable for locations where water availability is limited or costly.

Environmental impact and sustainability considerations

In terms of environmental impact and sustainability, air cooled condensing units have the edge over water cooled units. Air cooled systems use ambient air for cooling, eliminating the need for excessive water consumption and chemical treatment associated with water cooling. This makes them a more eco-friendly option, especially in areas facing water scarcity or strict environmental regulations.

In addition to their environmental benefits, air cooled condensing units also offer practical advantages for installation and maintenance. These units are typically easier to install and require less complex plumbing and infrastructure compared to water cooled systems. This can result in cost savings and reduced downtime during installation or maintenance, making air cooled units a more convenient option for businesses looking to minimize disruptions to their operations.

Practical considerations for installation and maintenance

When it comes to installation and maintenance, air cooled condensing units offer practical advantages over their water-cooled counterparts. Air cooled systems are easier to install as they don't require complex piping or access to a reliable water source like water-cooled units do. Additionally, maintenance for air-cooled condensing units is generally simpler and less costly, making them a more convenient choice for many businesses.

Now that we've explored the comparative analysis of efficiency and performance, environmental impact and sustainability considerations, as well as practical installation and maintenance aspects of air cooled vs. water cooled condensing units, it's clear that air cooled condensing units have numerous advantages that make them a compelling choice for refrigeration solutions in various industries.

How Does an Air Cooled Condenser Work?

Air cooled condensing units use a heat transfer process and cooling mechanisms to remove heat from the refrigerant gas, turning it into a liquid state. The condenser fan pulls in ambient air, which passes over the condenser coils, transferring heat and causing the refrigerant to cool down and condense.

Heat transfer process and cooling mechanisms

The heat transfer process in an air cooled condensing unit involves the refrigerant gas being compressed and then pumped through the condenser coils. As the fan draws in air, it removes heat from the refrigerant, causing it to liquefy. This process allows for efficient cooling of the refrigerant, ensuring optimal performance of the unit.

Energy efficiency and operational cost savings

One of the key advantages of air cooled condensing units is their energy efficiency and operational cost savings. By utilizing ambient air for cooling purposes, these units eliminate the need for additional water usage or cooling towers, resulting in reduced energy consumption and lower operational costs.

Innovative advancements in air cooled condenser technology

Innovative advancements in air cooled condenser technology have led to improved efficiency and performance. Manufacturers have developed enhanced coil designs, corrosion-resistant materials, and variable speed fans to optimize airflow and increase energy savings. These advancements contribute to more reliable and sustainable refrigeration solutions.

Air Cooled Condensing Unit Solutions for Cold Rooms

When it comes to reliable refrigeration solutions for cold rooms, RIGID's Bitzer Air Cooled Condensing Unit stands out as a top choice. This innovative unit is specifically designed to meet the demanding requirements of cold storage applications, offering exceptional temperature control and reliability.

RIGID's Bitzer Air Cooled Condensing Unit for refrigeration solution

RIGID's Bitzer Air Cooled Condensing Unit is a game-changer in the refrigeration industry, providing unmatched performance and efficiency for cold room applications. With its advanced technology and robust design, this unit ensures precise temperature control and reliable operation, making it an ideal solution for various cold storage needs.

Tailored design for local aquatic and seafood cooling and freezing

One of the key advantages of RIGID's Bitzer Air Cooled Condensing Unit is its tailored design for local aquatic and seafood cooling and freezing requirements. Whether it's a fish market or a seafood processing facility, this unit delivers the perfect balance of cooling capacity and energy efficiency to meet the specific demands of these applications.

Enhanced reliability and temperature control for cold storage applications

In addition to its tailored design, RIGID's Bitzer Air Cooled Condensing Unit offers enhanced reliability and precise temperature control for a wide range of cold storage applications. From preserving perishable goods to maintaining optimal conditions in pharmaceutical storage facilities, this unit ensures consistent performance under varying environmental conditions.

Remember that when considering air cooled condensing units for your cold room needs, RIGID's Bitzer Air Cooled Condensing Unit provides tailored solutions with enhanced reliability and temperature control.

Addressing the Challenges of Air Cooled Condensing Units

Air cooled condensing units can encounter common issues such as clogging of the condenser coils, which can lead to reduced efficiency and increased energy consumption. Regularly cleaning and maintaining the coils can help prevent this problem, ensuring optimal performance and longevity.

Identifying and troubleshooting common issues

One of the main problems with air cooled condensing units is the accumulation of dirt, dust, and debris on the condenser coils, hindering heat transfer and causing the system to work harder. This can result in higher energy costs and potential damage to the compressor. Regular inspection and cleaning of the coils are essential for preventing these issues.

Maintenance best practices for optimal performance and longevity

To maintain optimal performance and longevity of air cooled condensing units, it's crucial to follow maintenance best practices such as regularly checking for refrigerant leaks, ensuring proper airflow around the unit, replacing worn-out components, and scheduling routine professional inspections. These practices can help prevent breakdowns and costly repairs.

Maximizing the lifespan of air cooled condensing units

Maximizing the lifespan of air cooled condensing units involves proactive maintenance measures such as keeping the surrounding area clean to prevent debris from entering the unit, monitoring refrigerant levels, lubricating moving parts as needed, and addressing any unusual noises or vibrations promptly. These efforts can extend the lifespan of the unit while maintaining efficient operation

Conclusion

In conclusion, when it comes to choosing the right air cooled condensing unit for your needs, it's important to consider factors such as the size of your refrigeration system, the specific cooling requirements, and your budget. Ensuring efficiency and reliability in refrigeration solutions is crucial for maintaining optimal performance and minimizing operational costs. As for the future of air cooled condensing unit technology, we can expect continued advancements in energy efficiency and sustainability.

Choosing the Right Air Cooled Condensing Unit for Your Needs

When selecting an air cooled condensing unit, it's essential to assess the cooling capacity required for your specific application. Consider factors such as the size of your cold room or refrigerated space, as well as any unique temperature control needs. Consulting with a professional can help ensure that you choose a unit that meets your exact requirements.

Ensuring Efficiency and Reliability in Refrigeration Solutions

Efficiency and reliability are key considerations when it comes to refrigeration solutions. By opting for an air cooled condensing unit with high energy efficiency ratings and a proven track record of reliability, you can minimize operational costs while maximizing performance. Regular maintenance is also crucial for ensuring long-term efficiency.

When it comes to ensuring efficiency and reliability in refrigeration solutions, it's important to consider the environmental impact as well. Choosing an air cooled condensing unit that is designed with eco-friendly refrigerants can not only reduce your carbon footprint but also align with sustainability goals. Additionally, investing in a unit with advanced monitoring and diagnostic capabilities can help identify potential issues early on, preventing costly breakdowns and ensuring uninterrupted operation.

The Future of Air Cooled Condensing Unit Technology

As technology continues to evolve, we can expect further innovations in air cooled condensing units aimed at improving energy efficiency and environmental sustainability. Advancements in materials and design will likely lead to more efficient heat transfer processes and reduced environmental impact. The future looks promising for those seeking cutting-edge refrigeration solutions.