Direct Expansion Cooling System

Direct Expansion Evaporator Cooling System

RIGID DX evaporator system is a refrigeration module cooled directly by the refrigerant. It is a subsystem that can be in direct contact with the user's evaporator just like a cold plate. The refrigerant achieves cooling by circulating through the cold plate to remove heat from a space.

In fact, since no secondary coolant is needed, the system requires a minimum of components. There is no need to circulate cold air or to circulate coolant with fans or pumps. These additional components add complexity and inefficiency. Also, the secondary coolant (air or liquid) causes additional thermal resistance, which adds heat to the cooling system and reduces the net cooling capacity.

RIGID evaporator system is a refrigeration module with simple construction and minimal size, but the highest cooling energy efficiency. It is widely used in small refrigerators, small freezers, medical equipment, lasers, precision instruments, chips, etc.

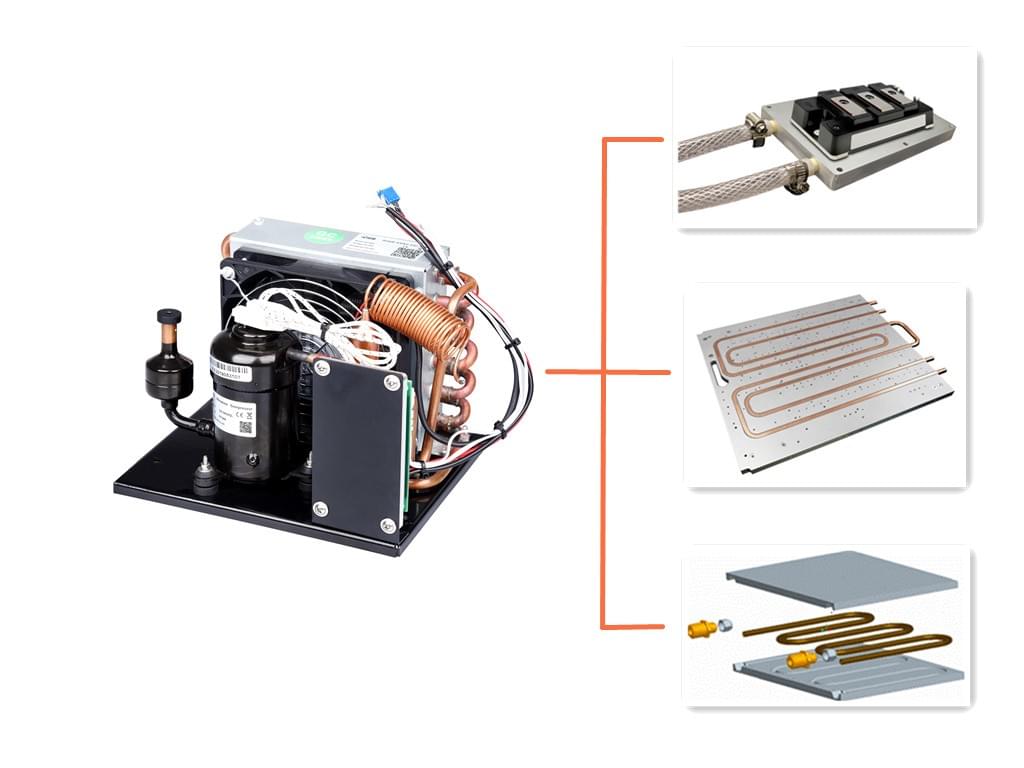

Chart 1. DX cooling components working principle

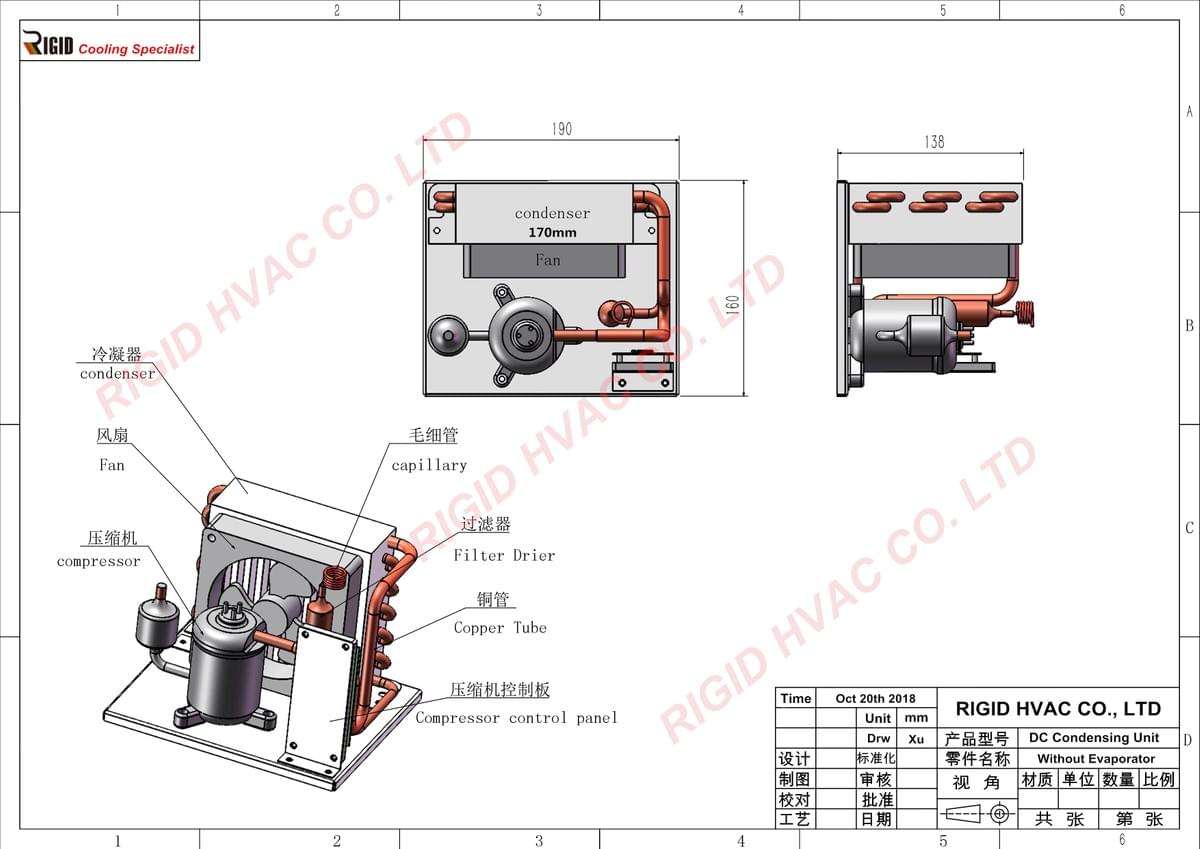

Chart 2. RIGID Expansion Evaporator System Drawing

RIGID direct expansion evaporator system consists of the basic four components: a compressor, a condenser, capillary, and an evaporator (optional).

Direct expansion means that there is no need for redundant coolant circuits, no pumps, no tanks, and the system refrigerant is circulated through the cold plate, directly cooling the required space.

Direct expansion systems in refrigeration systems are widely used in the market because of their simplicity, their ability to get rid of most ductwork and piping, and their ease of integration into the user's equipment.

Nowadays, direct expansion systems are widely used in commercial applications, such as precision instruments, medical equipment, cosmetic instruments, chips, lasers, laboratory equipment, etc.

RIGID direct expansion systems are compact, lightweight and very portable, making installation easier for the user and reducing the cost of the entire system.

Chart 3. RIGID Expansion Evaporator System Applications

Advantages of RIGID Direct Expansion System

- Working current: 1A ~10.3A (Maximum)

- Small Footprint: 190x160x138 mm (7.48x6.3x5.43 inch)

- Brushless dc compressor

- Low working noise: 48dB

- Low installation costs

- Low energy consumption

- Battery or dc power supply driven

- Minimum ceiling or wall space needed

- Easy integrated to customer's device, no maintenance

RIGID Direct Expansion System | DX system in HVAC | Cold Plate

In RIGID Expansion evaporator system, the refrigerant flows directly through the evaporator or customer cold plate or evaporators. The circulation is driven by our patent miniature dc compressor. The advantages of DX systems are very clear. This method eliminates the need for a liquid recirculation pump, water tank, and associated piping and connectors - all sources of failure and leakage.

Compared to commercially available liquid coolers, RIGID's DX expansion cooling system is 20 times smaller and 20 times lighter. Efficiency is improved by eliminating the losses associated with cooling liquids and the energy savings of driving the pump. The cooling capacity of the direct refrigerant is 45% greater than that of the liquid cooler.

More details of RIGID Direct Expansion Systems, → HERE!