Introduction

"RIGID is a miniature refrigerated compressor innovation leader in China. We keep looking for novel solutions in compact and portable cooling systems. We capture new technologies in mobile and compact cooling systems."

In the world of commercial refrigeration, understanding the intricacies of refrigeration compressors is crucial for businesses aiming to maintain efficiency and reduce operational costs. These devices play a fundamental role in cooling systems, making them essential components in various industries, from food storage to pharmaceuticals. With advancements in refrigeration compressor technology, businesses now have access to a range of options designed to enhance performance while minimizing energy consumption.

Understanding Commercial Refrigeration Compressors

At its core, a commercial refrigeration compressor is a mechanical device that increases the pressure of refrigerant vapor, facilitating the cooling process within a refrigeration system. The types of refrigeration compressors vary widely, each offering unique benefits and applications depending on specific business needs. By grasping how these machines function and their respective advantages, companies can make informed decisions about which compressor is best for refrigerators or other cooling systems.

Importance of Efficiency in Refrigeration

Efficiency in refrigeration isn't just a buzzword; it's a necessity that directly impacts operational costs and environmental sustainability. An efficient commercial refrigeration compressor not only reduces energy consumption but also extends the lifespan of the entire cooling system. As businesses strive to lower their carbon footprint and meet regulatory standards, understanding efficiency metrics becomes paramount for selecting appropriate types of refrigeration compressors.

Innovations in Refrigeration Compressor Technology

The landscape of refrigeration compressor technology has evolved dramatically over recent years, driven by innovations aimed at improving performance and energy efficiency. From smart compressors equipped with IoT capabilities to eco-friendly refrigerants that minimize environmental impact, these advancements are reshaping how businesses approach cooling solutions. Companies like RIGID are at the forefront of this revolution, pioneering mini compressor designs that cater specifically to modern demands for compactness and versatility in micro cooling applications.

Types of Refrigeration Compressors

Reciprocating Compressors Explained

Reciprocating compressors are often considered the workhorses of the refrigeration world. They operate using a piston-driven mechanism to compress refrigerant gas, making them suitable for a wide range of commercial refrigeration applications. What is a compressor in a refrigeration system? Simply put, it's the component responsible for circulating refrigerant through the system to maintain desired temperatures.

These compressors are known for their reliability and efficiency in smaller systems but can become less efficient as size increases. They are versatile enough to handle varying loads, but their mechanical complexity can lead to higher maintenance costs over time. If you're asking which compressor is best for refrigerators in smaller setups or older systems, reciprocating models often make the cut due to their proven track record.

Scroll Compressors: The Modern Choice

Scroll compressors have emerged as a modern choice for many commercial refrigeration applications due to their compact design and high efficiency. Unlike reciprocating models that rely on pistons, scroll compressors use two spiral-shaped scrolls that compress refrigerant quietly and smoothly. This innovation in refrigeration compressor technology results in lower noise levels and less vibration compared to traditional designs.

One of the standout features of scroll compressors is their energy efficiency; they typically have higher Energy Efficiency Ratios (EER) than other types of compressors. This makes them an attractive option for businesses looking to reduce energy costs while maintaining optimal cooling performance. If you’re considering which compressor is best for refrigerator units that require consistent operation without frequent cycling on and off, scroll models may very well fit your needs.

Screw Compressors for Heavy-Duty Cooling

When heavy-duty cooling is required, screw compressors come into play as robust workhorses capable of handling large volumes of refrigerant efficiently. These types of refrigeration compressors utilize two interlocking helical rotors that compress refrigerant continuously without pulsation—ideal for industrial applications where reliability is paramount. Their ability to operate effectively at varying load conditions makes them perfect candidates for large-scale commercial operations.

Screw compressors excel in situations where high capacity and low maintenance are essential; they tend to have longer lifespans compared to other compressor types due to fewer moving parts involved in their operation. However, they do require a more significant upfront investment but pay off with lower operational costs over time through energy savings and reduced downtime from repairs or replacements. For businesses focused on maximizing efficiency while dealing with demanding cooling requirements, screw compressors stand out as top contenders.

Efficiency Metrics in Compressors

In the world of commercial refrigeration, understanding efficiency metrics is essential for optimizing performance and reducing energy costs. With various types of refrigeration compressors available, it becomes crucial to evaluate their efficiency and performance. This section delves into energy efficiency ratios, performance evaluation criteria, and sustainability practices in refrigeration compressor technology.

Energy Efficiency Ratios and Their Impact

Energy Efficiency Ratios (EER) are critical metrics that gauge how effectively a refrigeration compressor converts electrical energy into cooling output. Higher EER values indicate greater efficiency, which can lead to significant cost savings over time for businesses relying on commercial refrigeration compressors. By selecting a compressor with a high EER, companies can not only reduce operational expenses but also lessen their environmental footprint—a win-win in today's eco-conscious market.

Understanding what is a compressor in a refrigeration system is vital when discussing EERs. Different types of refrigeration compressors have varying levels of efficiency based on design and application; for instance, scroll compressors often outperform reciprocating models in terms of EER. As innovations continue to emerge within refrigeration compressor technology, the importance of selecting an efficient model becomes increasingly evident.

Evaluating Performance: What to Look For

When evaluating the performance of different types of refrigeration compressors, several factors should be considered beyond just energy efficiency ratios. Noise levels, reliability ratings, and maintenance requirements play significant roles in determining which compressor is best for refrigerator applications or other cooling systems. Additionally, understanding how a refrigeration compressor works helps businesses identify potential issues before they arise—knowledge that can save time and money.

One key aspect to look for when assessing performance is the ability to maintain consistent temperatures under varying load conditions. This stability is particularly important in commercial settings where product quality must be preserved at all times. Furthermore, examining user reviews and expert recommendations can provide valuable insights into which models stand out among competitors.

Sustainability in Commercial Refrigeration

Sustainability has become an essential consideration for businesses investing in commercial refrigeration solutions today. The push towards eco-friendly refrigerants and energy-efficient designs aligns with global efforts to combat climate change while maintaining operational effectiveness within industries reliant on cooling systems. RIGID leads the charge by focusing on innovative mini compressor technologies that prioritize sustainability without sacrificing performance.

Moreover, adopting sustainable practices extends beyond just selecting efficient equipment; it also involves implementing proper maintenance routines that prolong the lifespan of your chosen systems—whether they are mini chillers or micro DC air conditioning units from RIGID's extensive lineup. As more companies recognize their role within environmental stewardship initiatives, the demand for reliable solutions like those offered by RIGID will continue to grow.

How a Refrigeration Compressor Works

Understanding how a refrigeration compressor works is crucial for anyone involved in commercial refrigeration. The heart of any cooling system, the compressor plays a pivotal role in maintaining the desired temperature by circulating refrigerants through various components. This process not only ensures efficient cooling but also highlights the importance of selecting the right types of refrigeration compressors for specific applications.

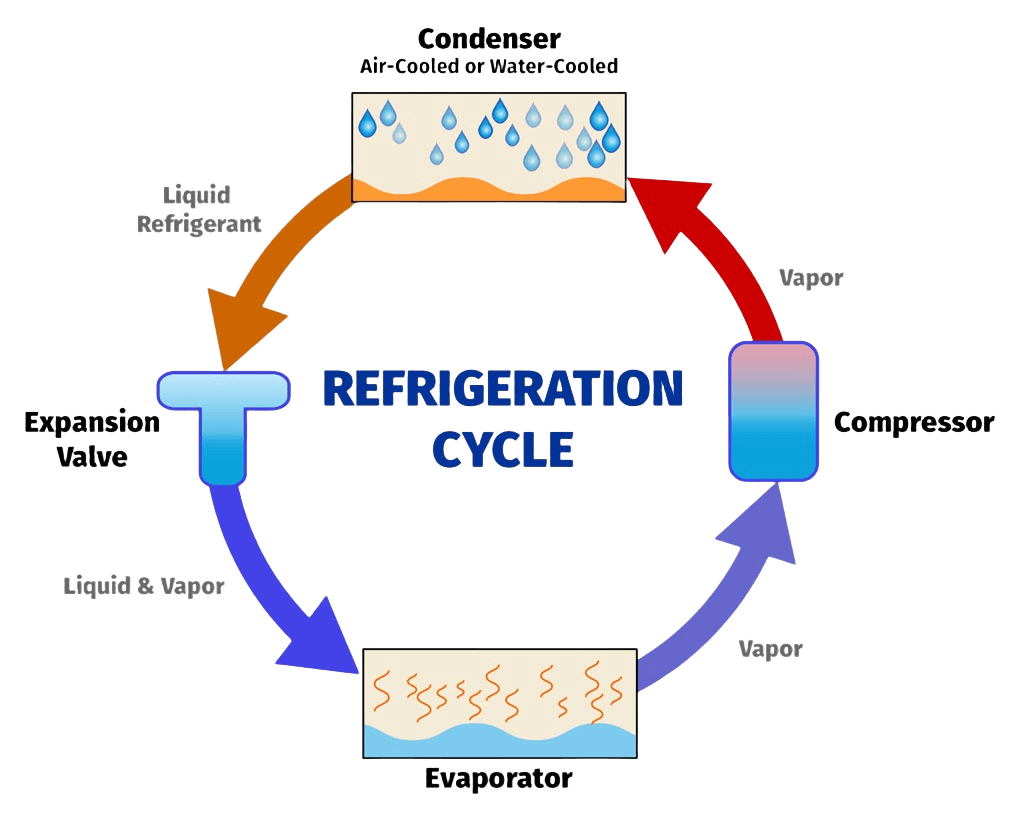

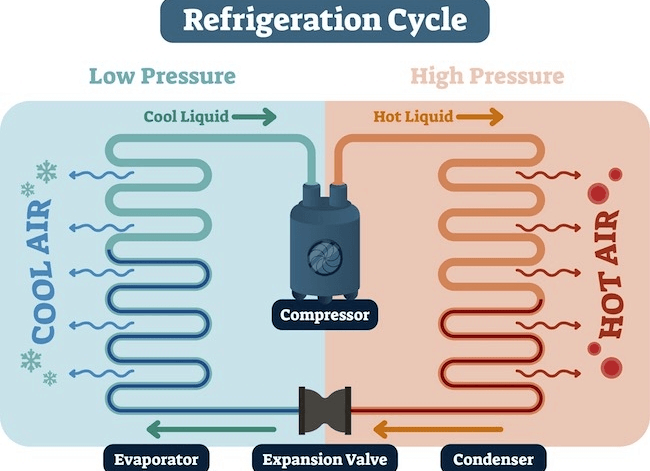

The Refrigeration Cycle Demystified

At its core, the refrigeration cycle involves four primary stages: compression, condensation, expansion, and evaporation. Initially, the compressor compresses low-pressure refrigerant gas into high-pressure gas, which then moves to the condenser where it releases heat and transforms into a liquid. This liquid refrigerant then passes through an expansion valve before entering the evaporator coil, where it absorbs heat from its surroundings—cooling your space effectively.

The cycle repeats as the refrigerant returns to the compressor as a low-pressure gas. Understanding this cycle is essential when evaluating different types of refrigeration compressors and their efficiency metrics. Ultimately, knowing how a refrigeration compressor works empowers businesses to make informed decisions about their cooling systems.

Key Components of a Compressor

A commercial refrigeration compressor consists of several key components that work harmoniously to facilitate cooling. These include the motor that drives the compressor mechanism, valves that control refrigerant flow, and various seals to maintain pressure integrity within the system. Additionally, many modern compressors incorporate advanced technologies that enhance performance and energy efficiency.

When considering which compressor is best for refrigerators or other applications, it's important to evaluate these components closely. High-quality materials and innovative designs can significantly impact both longevity and operational efficiency—qualities that RIGID excels in with its mini compressors and small chillers tailored for diverse needs.

The Role of Refrigerants in Efficiency

Refrigerants are vital players in any refrigeration system; they absorb and release heat during phase changes within the cycle we just discussed. The choice of refrigerant not only affects cooling performance but also has implications for environmental sustainability—a growing concern in today’s market for commercial refrigeration compressors. Selecting eco-friendly options can lead to improved energy efficiency while meeting regulatory standards.

Moreover, understanding different types of refrigeration compressors helps businesses choose systems compatible with modern refrigerants designed for maximum efficiency without harming our planet. RIGID's innovations focus on optimizing these interactions by developing mini compressors suitable for various eco-friendly refrigerants while maintaining superior performance levels tailored to client needs.

Choosing the Right Compressor

Selecting the right compressor for your commercial refrigeration needs is crucial for ensuring efficiency, performance, and cost-effectiveness. With various types of refrigeration compressors available, understanding their unique features can help businesses make informed decisions. The right choice not only enhances cooling capabilities but also aligns with operational goals.

Factors to Consider for Your Business

When choosing a commercial refrigeration compressor, several factors should be evaluated to meet your specific business requirements. First and foremost is the size and capacity needed; this will depend on the volume of products being stored or cooled. Additionally, energy efficiency plays a significant role in operational costs—selecting a model with a high Energy Efficiency Ratio (EER) can lead to substantial savings over time.

Another consideration is the type of refrigerant used in the system; certain refrigerants are more environmentally friendly than others and may comply better with regulations. Maintenance needs are also vital—some types of refrigeration compressors require more frequent servicing than others, impacting long-term operational efficiency. Lastly, think about your budget; while some advanced models may have higher upfront costs, they could ultimately save money through reduced energy consumption and lower maintenance expenses.

Which Compressor is Best for Refrigerators?

Determining which compressor is best for refrigerators involves assessing both performance and application requirements. Reciprocating compressors are often favored for their reliability and ability to handle varying loads effectively; they work well in residential settings or small commercial applications. On the other hand, scroll compressors have gained popularity due to their quieter operation and compact design—making them ideal for businesses that prioritize space-saving solutions without sacrificing efficiency.

For heavy-duty cooling needs in large-scale operations like supermarkets or warehouses, screw compressors offer robust performance with high capacity options. These types of refrigeration compressors excel at maintaining consistent temperatures even under significant load fluctuations. Ultimately, understanding how a refrigeration compressor works will guide you toward selecting the most suitable option based on your specific cooling demands.

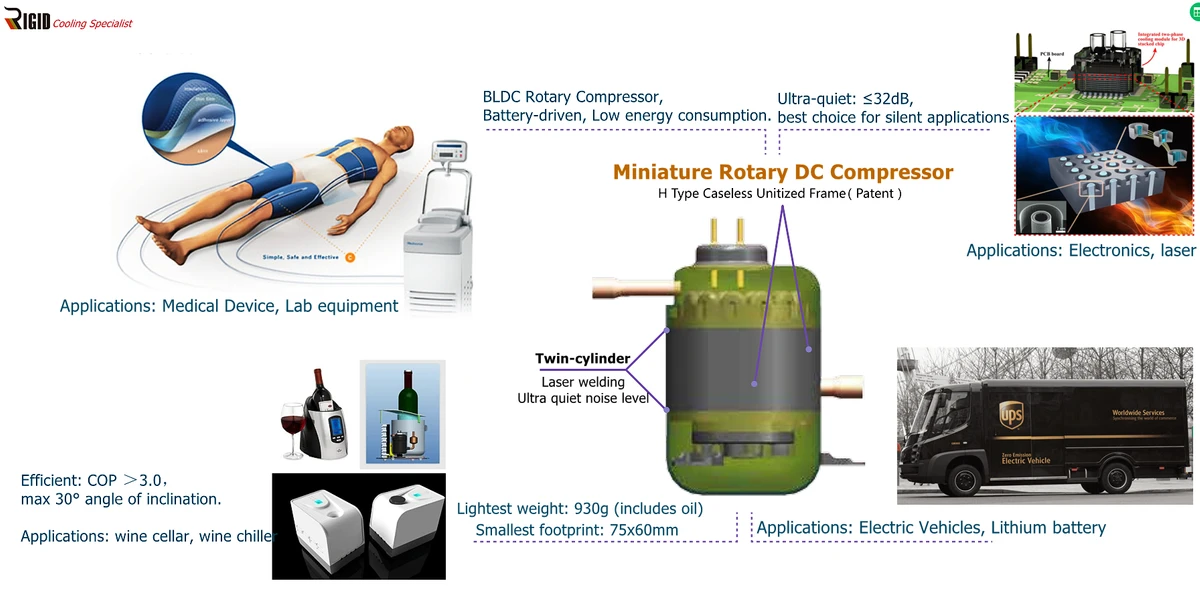

RIGID's Innovations in Mini Compressors

RIGID stands out as an innovation leader in mini compressor technology within China’s competitive landscape. Their commitment to capturing cutting-edge developments in mobile and compact cooling systems sets them apart from traditional manufacturers; RIGID’s mini compressors are designed specifically for micro refrigeration applications without compromising on quality or performance standards. With superior design features tailored to meet clients' budgets, RIGID offers custom-made solutions that enhance competitiveness across various industries.

Notably, RIGID's advancements extend beyond just mini compressors—they also specialize in small chillers and direct cooling systems that cater to diverse customer needs. By focusing on teamwork with clients during product development phases, RIGID ensures that every solution is tailored precisely to meet individual specifications while maintaining exceptional quality standards throughout production processes. This approach solidifies RIGID’s reputation as a pioneer in micro cooling technology.

Future Trends in Refrigeration Technology

The landscape of refrigeration technology is rapidly evolving, driven by the need for greater efficiency and sustainability. As businesses strive to optimize their operations, the integration of smart technologies and eco-friendly solutions is becoming paramount. The future will undoubtedly see a shift towards more advanced Commercial Refrigeration Compressors that not only perform better but also align with environmental standards.

Smart Compressors and IoT Integration

Smart compressors are revolutionizing how we think about refrigeration systems. By utilizing Internet of Things (IoT) integration, these units can communicate data in real-time, allowing for predictive maintenance and enhanced performance monitoring. This means businesses can easily track energy consumption, detect inefficiencies, and make informed decisions about which types of refrigeration compressors best suit their needs.

With advancements in Refrigeration Compressor Technology, smart features such as remote control capabilities and automated adjustments based on load conditions are becoming standard. Imagine a scenario where your compressor adjusts its operation automatically based on the temperature fluctuations in your environment—this is now possible! As companies look to answer the question What is compressor in refrigeration system? they will increasingly find that smart technology offers solutions tailored to modern demands.

The Push for Eco-Friendly Solutions

In an age where sustainability is at the forefront of business practices, eco-friendly solutions are not just an option; they're a necessity. Manufacturers are focusing on creating Commercial Refrigeration Compressors that utilize environmentally friendly refrigerants and energy-efficient designs to minimize their carbon footprint. This push towards greener alternatives ensures that businesses can operate without compromising the health of our planet.

The types of refrigeration compressors available today reflect this trend toward sustainability, with many models designed specifically to reduce energy consumption while maintaining high performance levels. Companies must ask themselves which compressor is best for refrigerators that prioritize eco-friendliness without sacrificing effectiveness or reliability. As regulations tighten around refrigerants and emissions, staying ahead with sustainable options will be crucial for competitive advantage.

RIGID's Role in Advancing Micro Cooling

RIGID stands at the forefront of innovation within the micro cooling industry, pushing boundaries with their cutting-edge mini compressor technologies. Known for superior design and uncompromising quality, RIGID captures new technologies that cater to mobile and compact cooling systems—perfectly aligning with current trends towards efficiency and sustainability in commercial refrigeration applications. Their commitment to custom-made solutions means clients receive tailored products that meet specific requirements while adhering to budget constraints.

As a leader in mini compressor innovation in China, RIGID understands what it takes to stay relevant amidst changing market demands. Their focus isn't just on producing standard units; they aim to redefine how businesses approach cooling systems by integrating advanced features that enhance performance while remaining environmentally conscious. With RIGID's advancements in micro cooling technology, businesses can expect reliable performance from their refrigeration systems while contributing positively towards ecological goals.

Conclusion

In the world of commercial refrigeration, selecting the right compressor is crucial for optimal performance and efficiency. With various types of refrigeration compressors available, understanding their unique characteristics can help businesses make informed decisions that align with their operational needs. As technology advances, innovations in Refrigeration Compressor Technology continue to reshape the industry, offering solutions that not only enhance cooling capabilities but also prioritize energy efficiency.

The Best Options for Commercial Refrigeration

When it comes to choosing the best options for commercial refrigeration, it's essential to evaluate the different types of refrigeration compressors available on the market. Reciprocating compressors are often favored for their reliability, while scroll compressors have emerged as a modern choice due to their quiet operation and energy efficiency. However, screw compressors may be ideal for heavy-duty cooling applications where robust performance is required—each type has its strengths tailored to specific requirements.

Maximizing Efficiency in Your System

Maximizing efficiency in your refrigeration system begins with understanding how a refrigeration compressor works and how it fits into your overall setup. By focusing on energy efficiency ratios and performance metrics, businesses can identify which compressor is best for refrigerators within their operations. Additionally, incorporating sustainable practices and eco-friendly refrigerants will not only enhance operational efficiency but also contribute positively to environmental goals.

Custom Solutions with RIGID's Expertise

RIGID stands at the forefront of mini compressor innovation in China, specializing in customized solutions tailored to meet diverse business needs. By leveraging cutting-edge technologies in mobile and compact cooling systems, RIGID provides clients with superior design and uncompromising quality across various miniature cooling applications—from mini water chillers to micro DC air conditioning units. Their commitment to understanding client budgets ensures that every solution boosts competitiveness while delivering exceptional performance.